Buffalo horn glasses are a unique and luxurious choice for eyewear, known for their distinctive beauty and eco-friendly properties. These frames are not only stylish but also durable, lightweight, and hypoallergenic. To ensure your buffalo horn glasses maintain their exquisite appearance and longevity, it’s essential to know how to care for them properly. In this comprehensive guide, we’ll provide you with valuable insights on how to care for buffalo horn glasses.

Buffalo Horn Materials

INatural horn is one of the oldest frame materials in the world. It has it own beautiful color and pattern, each piece unique, created as god intended.

The first horn glasses known to history appeared in Italy during the 13th century. Primitive glass-blown lenses were set into wooden or animal horn and then held before the face or perched on the nose. Mostly used by monks, these grew in popularity and the technology improved through the Renaissance.

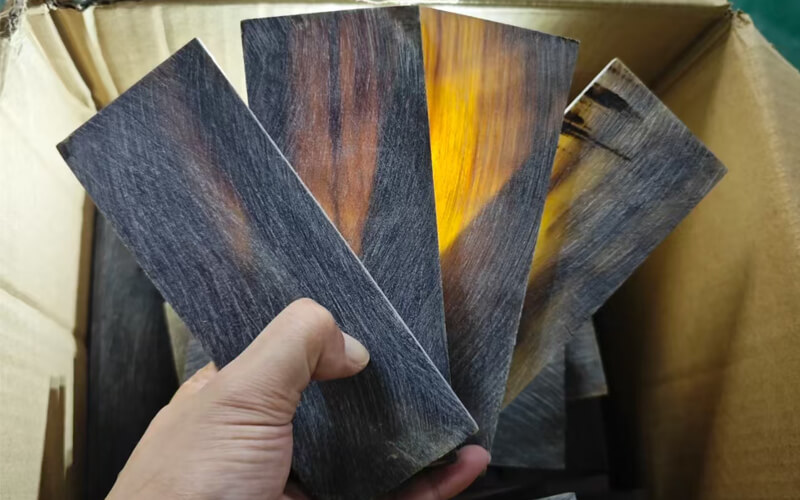

Whats are the Main Colors of Horn Eyewear?

The unparalleled grain and hues speak for themselves, and the wearer can choose from a multitude of horn shades.

Color options range from grey and anthracite tones to shades of brown and even white horn. And what is more, horn can be coloured using natural dyes so that numerous shades can be incorporated.

Nearly Black

Black with white lines

Brown

Brown Grey

Marble Brown

Brown with white lines

Blonde

What are the Properties of Horn Eyewear?

Properties of Horn Eyewear

The lightest of all the materials that can be used in sunglass and optical frames.

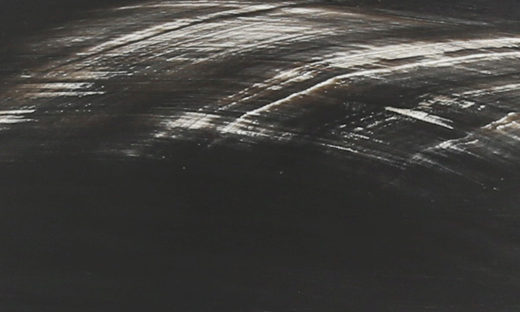

No other frame material has the warmth and feel of buffalo horn and every piece is unique. The way the light is reflected and the warm enticing appearance of the horn are inimitable. The exotic look and unique feel of horn is what many frame designers try to replicate with acetate frames.

Heat repellent: because it doesn’t absorb heat from sunlight, unlike metal frames. This keeps the face from overheating and developing excess blood pressure.

Comfort: Horn temple will bend and contour to the human face after 4 weeks of wearing.

Anti-Allergenic: The most skin-friendly material used in the making of glasses.

-

Buy Highend Buffalo Horn Eyewear in Bulk – 198639

$120.00 Select options This product has multiple variants. The options may be chosen on the product page -

Wholesale Fashion Buffalo Horn Sunglasses – 7550178

$120.00 Select options This product has multiple variants. The options may be chosen on the product page -

Wholesale Luxury Buffalo Horn Eyeglasses – 0035

$120.00 Select options This product has multiple variants. The options may be chosen on the product page -

Wholesale Retro Buffalo Horn Sunglasses – 17550179

$120.00 Select options This product has multiple variants. The options may be chosen on the product page

How to Produce Buffalo Horn Eyeglass?

1. Material Selection: Finding the Perfect Horn

The first step in making buffalo horn eyewear is selecting the right horn. Not all buffalo horns are created equal, so choosing high-quality material is crucial.

- Types of Horn: There are different types of buffalo horn, such as African and Indian buffalo horn. Each type has its own unique characteristics, like color, texture, and thickness. African horn might have more vibrant patterns, while Indian horn could offer a darker, more uniform appearance.

- Ethical Sourcing: It’s important to ensure the horn is ethically sourced. Buffalo horn is often a byproduct of the food industry, making it an eco-friendly option, but it’s still essential to work with suppliers who follow ethical practices.

The key here is to find horn pieces that are not only beautiful but also structurally sound. The better the quality of the horn, the more stunning the final product will be.

2. Horn Preparation: Getting the Material Ready

Once you’ve got your horn, the next step is to prepare it for crafting. This involves a few key processes:

- Cleaning and Sanitizing: First, the raw horn material needs to be thoroughly cleaned and sanitized. This ensures that any impurities are removed, leaving you with a clean, pure material to work with.

- Cutting the Horn: The horn is then cut into smaller, more manageable pieces, usually in the form of plates or slabs. These pieces will be used to create the frames.

- Flattening: Buffalo horn naturally has a curved shape, so to turn it into eyewear, it needs to be flattened. This is typically done by heating the horn and then pressing it flat. The heat softens the horn, making it pliable enough to shape without breaking.

This preparation stage is crucial for ensuring the horn is in the best possible condition for the later steps.

3. Layering and Laminating: Building Strength

Buffalo horn, by itself, is usually too thin to make durable eyewear. That’s where layering and laminating come in.

- Layering the Horn: Thin slices of horn are layered on top of each other to achieve the desired thickness. This is important because it gives the frames the strength they need to last a long time.

- Laminating: The layers are bonded together using natural or organic adhesives. The goal is to create a single, strong piece of horn that’s both durable and beautiful. It’s like creating a sandwich of horn layers, where each layer adds strength and stability.

This process not only enhances the durability of the frames but also allows for creative designs by mixing different slices with varied colors and patterns.

4. Frame Shaping: Bringing the Design to Life

Now that the horn is prepared, it’s time to cut it into the shape of the eyewear frames. This is where the magic starts to happen.

- Cutting the Frames: The laminated horn is cut into the rough shape of the frames using either templates or CNC machines. CNC machines are incredibly precise and can handle complex designs with ease, ensuring each pair of frames is perfectly shaped.

- Initial Sanding: After cutting, the edges of the frames will be rough. So, the frames are sanded down to smooth out these rough edges and refine the overall shape. This sanding process also helps to reveal the beautiful natural patterns of the horn.

At this stage, the frames start to look like actual glasses, but there’s still a lot of work to do.

5. Nose Bridge and Temple Construction: Shaping Comfort

The nose bridge and temples (the arms of the glasses) are essential for both comfort and fit. Here’s how they’re crafted:

- Shaping the Nose Bridge: The nose bridge is carefully shaped to ensure it sits comfortably on the wearer’s nose. This involves carving out the right curvature so the glasses rest evenly without slipping.

- Crafting the Temples: The temples are usually made from either solid pieces of horn or laminated layers, just like the frames. They need to be strong yet flexible, and they’re shaped to wrap around the ears comfortably.

- Attaching Hinges: Hinges are attached to the temples so they can fold. The choice between spring-loaded hinges (which offer flexibility) and fixed hinges (which provide a classic, sturdy feel) depends on the design and customer preference.

Getting these parts right is critical because they directly impact how the glasses feel when worn.

6. Handcrafting Details: Adding the Artistic Touches

Once the basic shape is done, it’s time to add those fine details that make buffalo horn eyewear stand out.

- Carving and Engraving: Skilled artisans might carve or engrave intricate designs into the horn, adding a unique touch to each pair of glasses. These details can range from subtle patterns to more elaborate designs, depending on the style of the eyewear.

- Polishing the Frames: The frames are then polished by hand to bring out the natural luster of the horn. This step reveals the stunning natural patterns and colors that make buffalo horn eyewear so desirable.

- Final Shaping: The frames are given a final check and any necessary adjustments are made to ensure they are perfectly shaped.

This stage is all about turning the eyewear into a work of art, with each piece of horn being unique in its patterns and hues.

7. Lens Cutting and Fitting: Completing the Glasses

No pair of glasses is complete without lenses. Here’s how they’re fitted into the buffalo horn frames:

- Cutting the Lenses: The lenses are cut to fit the specific shape of the frames. This requires precision cutting tools to ensure that the lenses fit snugly without any gaps.

- Fitting the Lenses: Once cut, the lenses are carefully fitted into the frames. This step requires a steady hand, as the lenses need to be secured without damaging them or the frames.

This is a crucial step that transforms the frames into functional eyewear.

8. Hand Polishing and Finishing: Bringing Out the Shine

Now that the lenses are in place, it’s time for the final polish and finish.

- Detailed Hand Polishing: The frames undergo a detailed hand polishing process to enhance the horn’s natural beauty. This brings out the unique colors and patterns, giving the eyewear a luxurious, glossy finish.

- Applying Oils or Waxes: Natural oils or waxes are applied to protect the horn and add an extra layer of shine. This not only makes the frames look stunning but also helps to preserve the horn over time.

- Final Inspection: The frames are carefully inspected to ensure there are no imperfections. They must be smooth, symmetrical, and perfectly crafted.

This final step is all about making sure the eyewear is ready to impress.

9. Assembly: Putting It All Together

With all the components ready, it’s time to assemble the glasses.

- Attaching Temples and Securing Lenses: The temples are attached to the frames, and the lenses are secured in place. Everything needs to be perfectly aligned to ensure the glasses are comfortable to wear and function properly.

- Final Adjustments: Any final tweaks are made to ensure that the frames fit perfectly and the lenses are securely held. The hinges are tested to make sure they move smoothly and the temples fold correctly.

After this step, the glasses are fully assembled and ready to wear.

10. Quality Control: Ensuring Perfection

Before the glasses are shipped out, they go through a rigorous quality control process.

- Thorough Inspection: Each pair of glasses is carefully inspected for any defects or imperfections. This includes checking the fit of the lenses, the alignment of the temples, and the overall finish of the frames.

- Durability Testing: The glasses are tested for durability, including how well the hinges hold up and whether the frames can withstand regular use.

- Final Polishing: If needed, the glasses are given one last polish to ensure they’re in perfect condition when they reach the customer.

Quality control is crucial for maintaining the high standards expected of buffalo horn eyewear.

11. Branding and Personalization: Adding the Final Touches

To make each pair of glasses unique, branding and personalization are added.

- Laser Engraving: Logos, custom designs, or even personalized messages can be laser engraved onto the frames. This adds a unique and professional touch to the eyewear.

- Custom Touches: For a truly bespoke product, additional touches like gemstone inlays or metal accents can be added to the frames. These details can make the eyewear even more special and luxurious.

This step ensures that each pair of glasses is as unique as the person who wears them.

12. Packaging and Presentation: The Final Flourish

The last step is packaging the glasses in a way that reflects their luxury status.

- Luxury Packaging: The glasses are placed in high-quality, often eco-friendly packaging that protects them during shipping and adds to the overall unboxing experience. This might include a branded case, a cleaning cloth, and care instructions.

- Protection for Shipping: The packaging is designed to ensure the glasses arrive in perfect condition, no matter how far they have to travel.

The presentation is the final touch that turns a great product into a memorable experience.

Receive Custom Guidance

Looking for the perfect custom eyewear to represent your brand?

Reach out to Eyewearbeyond for expert guidance on choosing the best materials, styles, and customizations for your eyewear collection!

How to Care for Buffalo Horn Glasses

1. Cleaning Your Buffalo Horn Glasses

Cleaning your buffalo horn glasses is the first and most crucial step in their care. Follow these steps for effective cleaning:

Use a Gentle Cleaning Solution:

Avoid using harsh chemicals or alcohol-based cleaners, as they can damage the horn’s natural luster. Instead, opt for a mild dish soap mixed with lukewarm water.

Dampen a Soft Cloth:

Dip a clean, soft cloth into the soapy water mixture. Ensure the cloth is only slightly damp, not soaking wet.

Wipe the Frames:

Gently wipe the frames, including the front and temple parts. Pay special attention to any areas with accumulated dirt or oils.

Dry with a Soft, Dry Cloth:

After cleaning, use a separate, dry, soft cloth to remove any remaining moisture. Buff the frames to restore their natural shine.

Buffalo horn frames may be resilient, but prolonged exposure to direct sunlight can cause the horn to dry out and lose its natural sheen. When not in use, store your glasses in a case or a shaded area to protect them from UV rays.

2. Avoid Excessive Sun Exposure

Buffalo horn frames may be resilient, but prolonged exposure to direct sunlight can cause the horn to dry out and lose its natural sheen. When not in use, store your glasses in a case or a shaded area to protect them from UV rays.

3. Handle with Care

Gently handle your buffalo horn glasses to prevent accidental damage. Avoid bending the frames or putting excessive pressure on them, especially at the hinges. When you remove or put on your glasses, hold them by the temples, not the front part.

4. Regular Maintenance

Gently handle your buffalo horn glasses to prevent accidental damage. Avoid bending the frames or putting excessive pressure on them, especially at the hinges. When you remove or put on your glasses, hold them by the temples, not the front part.

5. Avoid Extreme Temperatures

While buffalo horn adapts to your body temperature, it’s best to avoid exposing your glasses to extreme temperatures. Don’t leave them in your car on a hot summer day or in freezing cold environments.

6. Store Properly

When you’re not wearing your buffalo horn glasses, store them in a protective case. A sturdy case will shield them from dust, moisture, and potential impacts.

7. Regularly Clean Nose Pads

If your buffalo horn glasses have nose pads, clean them with a gentle solution to prevent the buildup of oils and debris. This can help maintain a comfortable fit on your nose.

Buffalo horn glasses are more than just eyewear; they’re a statement of individuality and a commitment to sustainable fashion. To ensure they continue to serve you well and look their best, it’s essential to care for them properly. By following the steps outlined in this comprehensive guide, you can enjoy the beauty and longevity of your buffalo horn glasses for years to come. With the right care, your glasses will remain a unique and eco-friendly accessory that enhances your style and comfort.

Conclusion

Producing buffalo horn eyewear is a process that requires skill, patience, and a keen eye for detail. From selecting the perfect horn to adding the final touches, every step is carefully crafted to create eyewear that’s not only beautiful but also durable and unique. Buffalo horn eyewear isn’t just a product—it’s a piece of art that reflects the craftsmanship and dedication of those who make it. Whether you’re drawn to it for its natural beauty, its luxury appeal, or its sustainable origins, buffalo horn eyewear is a truly special accessory that stands the test of time.

FAQ: A Comprehensive Guide to Buffalo Horn Frames

1. What makes buffalo horn eyewear special compared to other materials?

- Buffalo horn eyewear is unique due to its natural beauty, lightweight feel, and hypoallergenic properties. Each frame is one-of-a-kind, showcasing the natural patterns and colors of the horn. Additionally, buffalo horn frames are eco-friendly, as they are often made from ethically sourced horn, a byproduct of the food industry.

2. How is buffalo horn selected for making eyewear?

- Selecting the right buffalo horn involves choosing high-quality pieces with the desired color, texture, and thickness. Horns from different regions, like African or Indian buffalo, offer varying characteristics. Ethical sourcing is also crucial to ensure the horn is obtained responsibly.

3. What are the steps involved in preparing buffalo horn for eyewear?

- The preparation process includes cleaning and sanitizing the raw horn, cutting it into manageable pieces, and flattening it through heating and pressing. This preparation is essential to ensure the horn is in the best condition for crafting durable and beautiful eyewear.

4. Why is layering and laminating necessary in buffalo horn eyewear production?

- Buffalo horn is naturally thin, so layering and laminating thin slices of horn are necessary to achieve the desired thickness and strength for eyewear. This process not only enhances durability but also allows for creative designs by mixing different layers with varied colors and patterns.

5. How are buffalo horn frames shaped during production?

- After preparing and laminating the horn, the material is cut into the rough shape of the eyewear frames using templates or CNC machines for precision. The frames are then sanded to smooth out rough edges and refine the shape, revealing the natural beauty of the horn.

6. What makes the nose bridge and temples in buffalo horn eyewear comfortable?

- The nose bridge is carefully shaped to sit comfortably on the wearer’s nose, and the temples are designed to wrap around the ears without causing discomfort. The natural flexibility of buffalo horn allows it to contour to the face over time, ensuring a custom fit.

7. Are buffalo horn frames customizable?

- Yes, buffalo horn frames can be customized with intricate carvings, engravings, and other artistic details. Skilled artisans can add unique patterns or designs to the frames, making each pair of glasses a true work of art.

8. How are lenses fitted into buffalo horn frames?

- Lenses are cut to precisely fit the shape of the buffalo horn frames. They are carefully secured into the frames without causing damage, ensuring a snug and secure fit that transforms the frames into functional eyewear.

9. What steps are involved in the final polishing and finishing of buffalo horn eyewear?

- The final steps include detailed hand polishing to enhance the natural shine of the horn, applying oils or waxes for protection and added luster, and conducting a thorough inspection to ensure the frames are flawless and ready for wear.

10. How can buffalo horn eyewear be personalized or branded?

- Buffalo horn eyewear can be personalized through laser engraving or hand engraving, allowing for logos, custom designs, or personal messages to be added. Additional touches, such as gemstone inlays or metal accents, can further enhance the uniqueness of the frames.

11. What type of packaging is used for buffalo horn eyewear?

- Buffalo horn eyewear is typically packaged in high-quality, often eco-friendly materials that protect the glasses during shipping. Luxury packaging may include a branded case, cleaning cloth, and care instructions, enhancing the overall unboxing experience.

12. How should buffalo horn eyewear be cared for?

- Buffalo horn eyewear should be cleaned with a gentle solution, protected from excessive sun exposure, handled with care to avoid bending or pressure, and stored in a protective case when not in use. Regular maintenance, such as cleaning nose pads and avoiding extreme temperatures, will help preserve the beauty and longevity of the frames.

This FAQ section should help you better understand the process and care involved in producing and maintaining buffalo horn eyewear. If you have any more questions or need further information, feel free to reach out!

Clarify Your Questions

Still have questions about custom eyewear services?

Contact us for expert insights and tailored solutions!