Injection molding technology plays an indispensable role in the eyewear manufacturing industry. This highly efficient and precise manufacturing method enables companies to rapidly produce diverse eyewear products that cater to the needs of different consumers. In this process, material selection is critical to the performance, comfort, and durability of the eyewear. Each material comes with its unique advantages and suitable applications, making it valuable for both eyewear manufacturers and consumers to understand these materials in depth.

Overview of Common Materials

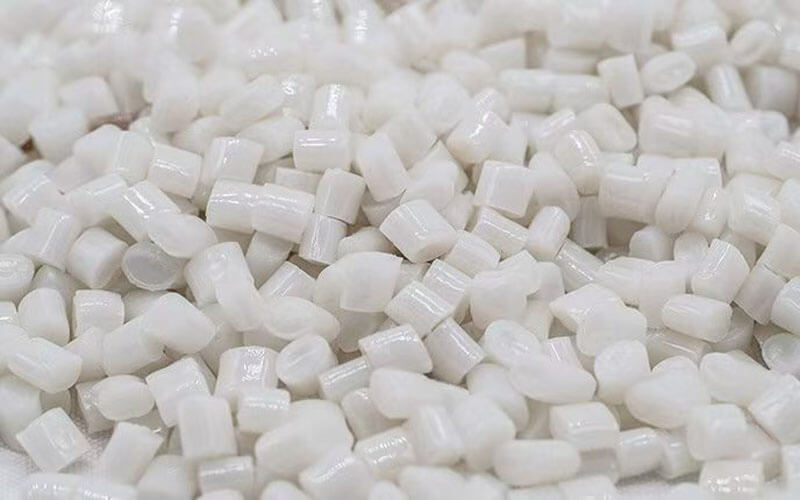

Injection molding technology is widely used in eyewear manufacturing primarily because it can handle various types of materials, particularly thermoplastics and bio-based polymers. These materials are not only easy to process but can also meet different market demands in multiple ways.

Thermoplastics

Thermoplastics are among the most common materials used in eyewear production. Their defining characteristic is that they soften when heated and harden when cooled, making them ideal for the injection molding process. Thermoplastics can be easily reprocessed, which helps reduce production costs and minimize waste. Here are some common thermoplastics and their applications in eyewear manufacturing:

| Thermoplastic | Characteristics | Suitable Eyewear Types |

| Polycarbonate (PC) | High transparency, impact resistance, UV protection | Sunglasses, safety glasses, protective eyewear |

| Nylon | High strength, chemical resistance | Sports eyewear, children’s eyewear, industrial protective eyewear |

| Acrylonitrile Butadiene Styrene (ABS) | Rigid, lightweight | Fashion eyewear, reading glasses, low-cost eyewear |

Polycarbonate is a representative material in the thermoplastics category, widely used in the production of sunglasses and protective eyewear due to its high transparency and excellent impact resistance. Nylon is known for its strength and durability, making it particularly suitable for sports eyewear that needs to withstand high-impact activities. ABS is another common thermoplastic that is favored for its rigidity and lightweight properties, often used in low-cost and rapidly iterated fashion eyewear products.

Bio-Based Polymers

With the growing awareness of environmental issues, bio-based polymers have become a popular material in eyewear manufacturing. These materials are derived from renewable resources such as corn, sugarcane, or other plants and offer the advantage of reducing the carbon footprint. In addition to their environmental benefits, bio-based polymers perform well in functionality and processability, meeting various design requirements in eyewear manufacturing.

Common bio-based polymers include polylactic acid (PLA) and other polymers derived from plant materials. While these materials are still gradually gaining traction in eyewear manufacturing, they have already shown great potential, especially for brands that aim to reduce their environmental impact.

Detailed Material Introduction

To further understand the materials used in injection molded eyewear, let’s delve into some of the most common materials and explore their applications in different types of eyewear.

TR90

TR90 is a high-performance memory plastic known for its excellent flexibility and impact resistance. TR90 is not only lightweight and comfortable to wear, but it can also withstand high impacts and chemical corrosion. Due to these characteristics, TR90 is commonly used in the following types of eyewear:

- Sports Eyewear: The high impact resistance of TR90 makes it an ideal choice for athletes and outdoor enthusiasts. These glasses frequently face falls and collisions, and TR90 material can effectively absorb impacts, reducing the risk of eyewear damage.

- Casual Eyewear: For everyday wearers, the lightweight and comfort of TR90 are crucial, particularly for those who wear glasses for extended periods.

TR90 is suitable not only for molding complex frame designs but also for producing various colors and styles through injection molding, meeting the personalized needs of different consumers.

-

Bulk Buy TR90 Optical Frames – 2223

$50.00 Select options This product has multiple variants. The options may be chosen on the product page -

Bulk Wholesale TR90 Optical Frames – 2095

$50.00 Select options This product has multiple variants. The options may be chosen on the product page -

Bulk Wholesale TR90 Optical Frames Supplier – KY58092

$50.00 Select options This product has multiple variants. The options may be chosen on the product page -

Buy Fashion TR90 Eyewear in Bulk – 8600

$50.00 Select options This product has multiple variants. The options may be chosen on the product page

Cellulose Acetate

Cellulose acetate is a classic eyewear material commonly used in manufacturing mid-to-high-end eyewear frames. It has excellent texture and dyeing capabilities, making it particularly popular in luxury brands and fashion eyewear. The main applications of cellulose acetate include:

- Luxury Brand Eyewear: High-end designs and rich color options make cellulose acetate a popular material in the luxury market. It not only looks premium but also provides exceptional comfort.

- Fashion Eyewear: Due to its ease of dyeing, designers can quickly produce a variety of eyewear styles according to fashion trends.

Although cellulose acetate is relatively expensive to produce, its high quality and stylish appearance make it the preferred material for many high-end eyewear brands.

-

Buy Acetate Sunglasses in Bulk – VS9004

$90.00 Select options This product has multiple variants. The options may be chosen on the product page -

Buy Wholesale Acetate Sunglasses in Bulk – S32101

$90.00 Select options This product has multiple variants. The options may be chosen on the product page -

Highend Acetate Sunglasses Supplier – Vintage 9523

$90.00 Select options This product has multiple variants. The options may be chosen on the product page -

Wholesale Acetate Sunglasses Distributor – 882218S

$90.00 Select options This product has multiple variants. The options may be chosen on the product page

Polycarbonate (PC)

Polycarbonate is known for its excellent impact resistance and high transparency, making it a common material for safety glasses and sunglasses. Here are the main application areas of polycarbonate:

- Safety Glasses: In industrial or laboratory environments, polycarbonate can provide superior eye protection, preventing debris, chemicals, or other hazardous materials from damaging the eyes.

- Sunglasses: The UV protection feature of polycarbonate makes it ideal for outdoor activities. It can effectively filter harmful UV rays while ensuring clear vision in bright light.

- Children’s Eyewear: For active children, the durability and lightweight nature of polycarbonate are crucial. It can withstand the drops and bumps of daily activities, ensuring the safety and longevity of the eyewear.

In addition, polycarbonate has shatter-resistant properties, meaning the lenses do not easily break even under strong impact, which further enhances its value in safety and outdoor eyewear.

Copolyester

Copolyester materials (such as Eastman Tritan™) are also widely used in injection molded eyewear. The durability, transparency, and BPA-free properties of copolyester make it an ideal choice for modern eyewear products. The applications of copolyester in eyewear include:

- Reading Glasses: The transparency and durability of copolyester ensure a clear view and comfortable wear for extended periods.

- Fashion Eyewear: Copolyester materials meet the aesthetic needs of fashion eyewear while providing environmental and health benefits, making them suitable for health-conscious and eco-friendly consumers.

Copolyester materials also have excellent impact resistance and chemical corrosion resistance, ensuring that eyewear maintains its high performance in various environments.

Acrylonitrile Butadiene Styrene (ABS)

ABS is a rigid, lightweight material commonly used in the manufacturing of structural eyewear frames. Its main applications include:

- Structural Eyewear: The rigidity of ABS allows it to support heavier lenses, making it particularly suitable for eyewear designs that require additional strength.

- Fast Fashion Eyewear: Due to its ease of processing, manufacturers can quickly produce eyewear styles that align with current trends, meeting the fast-paced demand of the market.

ABS also has good impact resistance and durability, ensuring the stability and long life of eyewear in everyday use.

The Rise of Eco-Friendly Materials

With the increasing global focus on environmental issues, eyewear manufacturers are gradually turning to recycled materials and biodegradable materials. These materials not only reduce waste generation but also significantly reduce the carbon footprint during production.

Recycled Materials

Recycled materials are increasingly being used in injection molding processes. These materials are made by recycling waste plastics, which can significantly reduce reliance on virgin plastics. The advantages of using recycled materials in eyewear manufacturing include:

- Environmental Benefits: Using recycled materials can reduce waste, decrease environmental pollution, and reduce reliance on fossil fuels.

- Economic Benefits: Since recycled materials are relatively low in cost, using them can help companies lower production costs while enhancing their eco-friendly image.

Recycled plastics can be repurposed through injection molding to produce a variety of environmentally friendly eyewear.

Biodegradable Materials

Biodegradable materials represent an important trend in future eyewear production. These materials can decompose in natural environments, reducing long-term environmental impacts. Eyewear products made from biodegradable materials not only comply with sustainable development requirements but also cater to the growing demand for eco-friendly products. The application areas of biodegradable materials include:

- Eco-Friendly Eyewear: Designed specifically for environmentally conscious consumers, these glasses are typically made from biodegradable plastics that can naturally decompose without compromising performance.

- Fashion Eyewear: As eco-fashion rises, biodegradable materials are increasingly being used in fashion eyewear design.

These materials can decompose naturally within a certain time frame without causing permanent damage to the environment, making them an essential part of future green design.

Receive Custom Guidance

Looking for the perfect custom eyewear to represent your brand?

Reach out to Eyewearbeyond for expert guidance on choosing the best materials, styles, and customizations for your eyewear collection!

Factors Influencing Material Selection

In the production of injection molded eyewear, the factors influencing material selection primarily include cost, production efficiency, design requirements, aesthetics, and market demand.

Cost and Production Efficiency

One significant advantage of injection molding is its high production efficiency, allowing for the rapid manufacture of large quantities of eyewear. However, the cost and processability of different materials vary. Thermoplastics are commonly used due to their ease of processing, while bio-based materials may occupy a larger market share in the future due to their environmental advantages. Manufacturers need to balance material costs and production efficiency to meet market demand for cost-effective products.

Design Requirements and Aesthetics

The physical properties of different materials, such as flexibility, hardness, and color adaptability, directly affect the design freedom of eyewear. For example, TR90 is suitable for complex frame designs due to its flexibility, while cellulose acetate is preferred for its dyeing capabilities, making it ideal for developing personalized and fashionable styles.

Market Demand and Consumer Preferences

Market demand is one of the most important factors determining material selection. For environmentally conscious consumers, eyewear made from recycled and bio-based materials will be more appealing. At the same time, consumer focus on comfort and durability has driven the widespread use of TR90 and polycarbonate materials.

Conclusion

In the production of injection molded eyewear, material selection directly determines the product’s performance, quality, and market positioning. The use of thermoplastics, bio-based polymers, and eco-friendly materials not only meets the needs of different markets butIn the production of injection molded eyewear, material selection directly determines the product’s performance, quality, and market positioning. The use of thermoplastics, bio-based polymers, and eco-friendly materials not only meets the needs of different markets but also paves the way for future sustainable development in the eyewear industry. Manufacturers must carefully consider various factors, including cost, design, market demand, and environmental impact, to produce high-quality eyewear that satisfies consumer expectations and stands out in a competitive market.

Conclusion

The combination of injection molding technology and these quality materials allows eyewear products to achieve unprecedented breakthroughs in design and functionality. In the future, we can expect more innovative and environmentally friendly materials to be applied in eyewear manufacturing, providing consumers with more choices and driving the industry towards more sustainable and intelligent development. By making informed material choices, manufacturers can not only improve product performance but also distinguish themselves in an increasingly competitive market.

FAQ: Injection Molded Eyewear Materials

1. What are the most common materials used in injection molded eyewear?

The most common materials used in injection molded eyewear include TR90, polycarbonate, nylon, ABS (Acrylonitrile Butadiene Styrene), cellulose acetate, and copolyester (e.g., Eastman Tritan™). These materials are chosen for their flexibility, durability, impact resistance, and ease of processing, making them ideal for various types of eyewear.

2. Why is TR90 popular for sports and casual eyewear?

TR90 is popular for sports and casual eyewear due to its high flexibility, lightweight nature, and excellent impact resistance. These characteristics make TR90 frames comfortable for long periods and resilient to the physical demands of sports and outdoor activities.

3. What makes polycarbonate suitable for sunglasses and safety glasses?

Polycarbonate is highly valued in the production of sunglasses and safety glasses because of its superior impact resistance, high transparency, and UV protection capabilities. These properties ensure that polycarbonate lenses can withstand tough conditions while protecting the eyes from harmful UV rays and other potential hazards.

4. How is cellulose acetate used in eyewear production?

Cellulose acetate is commonly used in mid-to-high-end eyewear frames. It is appreciated for its excellent texture, ease of dyeing, and comfort. This material is often seen in luxury and fashion eyewear due to its ability to support vibrant colors and intricate designs.

5. What are bio-based polymers, and how are they used in eyewear?

Bio-based polymers are environmentally friendly materials derived from renewable resources like corn and sugarcane. In eyewear, these materials are used to reduce the carbon footprint of production while still providing the necessary durability and flexibility. Polylactic acid (PLA) is a common example of a bio-based polymer used in sustainable eyewear designs.

6. Are there any eco-friendly materials used in injection molded eyewear?

Yes, eco-friendly materials such as recycled plastics and biodegradable polymers are increasingly being used in injection molded eyewear. Recycled materials help reduce waste and reliance on virgin plastics, while biodegradable materials are designed to decompose naturally, minimizing environmental impact.

7. How do different materials affect the design and aesthetics of eyewear?

Different materials offer varying levels of design freedom. For instance, TR90’s flexibility allows for complex frame designs, while cellulose acetate’s excellent dyeing capabilities make it ideal for creating vibrant, fashionable eyewear. The choice of material impacts the final product’s look, feel, and overall appeal.

8. What factors influence the selection of materials for injection molded eyewear?

Material selection is influenced by factors such as cost, production efficiency, design requirements, aesthetics, market demand, and environmental considerations. Manufacturers balance these factors to produce eyewear that meets consumer expectations and maintains competitiveness in the market.

9. How does ABS compare to other materials in eyewear manufacturing?

ABS is known for its rigidity and lightweight nature, making it a good choice for structural eyewear frames that require extra strength without adding much weight. It’s commonly used in fast fashion eyewear and low-cost options where rapid production and trend alignment are key.

10. What future trends are expected in the use of materials for injection molded eyewear?

Future trends include the increased use of sustainable and eco-friendly materials, such as biodegradable plastics and advanced bio-based polymers. These materials will likely become more prevalent as consumer demand for environmentally responsible products grows, and as manufacturers seek to reduce their environmental footprint.

Request a Free Quote

Wondering how to budget for your custom eyewear order?

Contact us to receive a tailored quote designed specifically for your eyewear needs!