Titanium is widely used in metal eyewear manufacturing due to its lightweight, high strength, and corrosion resistance. As consumers increasingly seek comfort and durability, titanium eyewear has become popular for its outstanding performance and modern design. This article explores the application of titanium in metal eyewear, analyzing its material properties, manufacturing processes, and market trends, while highlighting the importance of titanium eyewear in the contemporary eyewear industry.

1. Properties and Advantages of Titanium

Lightweight

Titanium has a density of only 4.5g/cm³, making it lighter than other commonly used metals such as stainless steel and aluminum. This lightweight property ensures that titanium eyewear places minimal pressure on the nose and ears, even during extended wear, significantly enhancing comfort. As a result, titanium eyewear is the top choice for consumers who prioritize a comfortable wearing experience.

High Strength

Despite being lightweight, titanium is extremely strong and can withstand various impacts and pressures encountered in daily use. With excellent yield and tensile strength, titanium eyewear effectively resists external forces, ensuring the frames do not easily deform or break. This characteristic makes titanium eyewear particularly advantageous in terms of durability and safety, especially for users who wear glasses during sports or outdoor activities.

Corrosion Resistance

Titanium offers outstanding corrosion resistance, remaining stable in humid, acidic, and alkaline environments. This property makes titanium eyewear ideal for use in coastal, tropical, and other high-humidity environments, where it can maintain its appearance and performance over time without rusting or corroding. For consumers living in humid conditions, titanium eyewear is an excellent choice.

Biocompatibility

Titanium is non-toxic and does not cause allergic reactions, making it widely used in the medical field for items such as artificial joints and implants. For consumers with sensitive skin or allergies, titanium eyewear is a safe option that does not cause skin irritation or allergic reactions, ensuring the wearer’s health and comfort.

Summary of Titanium Advantages

The following table summarizes the key advantages of titanium in eyewear manufacturing:

| Property | Description | Applicable Scenarios |

| Lightweight | Low density and weight reduce the burden of wearing | Daily wear, extended wear |

| High Strength | High yield and tensile strength resist impacts | Sports, outdoor activities |

| Corrosion Resistance | Stable in humid, acidic, and alkaline environments | High-humidity environments, coastal areas, tropical regions |

| Biocompatibility | Non-toxic, does not cause allergic reactions | Medical devices, consumers with sensitive skin |

-

Bulk Wholesale Designer Titanium Eyeglasses – 80995

$90.00 Select options This product has multiple variants. The options may be chosen on the product page -

Bulk Wholesale Retro Titanium Glasses Frames – 202314

$90.00 Select options This product has multiple variants. The options may be chosen on the product page -

Buy High Quality Titanium Eyeglasses in Bulk – EP

$90.00 Select options This product has multiple variants. The options may be chosen on the product page -

Buy Wholesale 18K Gold Eyewear in Bulk – 8215

$190.00 Select options This product has multiple variants. The options may be chosen on the product page

2. Titanium Eyewear Manufacturing Process

Refining and Processing of Titanium

Titanium refining and processing are complex, involving multiple steps to extract pure titanium or titanium alloys from ore. Typically, titanium ore undergoes chlorination and reduction to produce sponge titanium, which is then processed into titanium ingots through vacuum smelting. These titanium ingots are further processed into titanium sheets or wires suitable for eyewear manufacturing, laying the foundation for subsequent production.

Application of Titanium Alloys in Eyewear Frames

To enhance the properties of titanium, manufacturers often mix it with other metals (such as aluminum and vanadium) to create titanium alloys. Titanium alloys combine the lightweight, high strength, and corrosion resistance of titanium while improving workability and elasticity, making them ideal for manufacturing complex eyewear frames. Different alloy compositions offer designers various options to meet diverse market needs.

| Type of Titanium Alloy | Main Components | Properties | Application Scenarios |

| TA1 (Pure Titanium) | Titanium content ≥99.5% | Lightweight, high strength, excellent corrosion resistance | High-end eyewear frames, medical devices |

| TC4 (Titanium Alloy) | Titanium + aluminum, vanadium | High strength, good workability, heat resistance | Complex eyewear frames, sports eyewear |

| TB5 (Titanium Alloy) | Titanium + aluminum, vanadium, molybdenum | Extremely high tensile strength and fatigue resistance | Eyewear frames requiring ultra-high strength, professional sports eyewear |

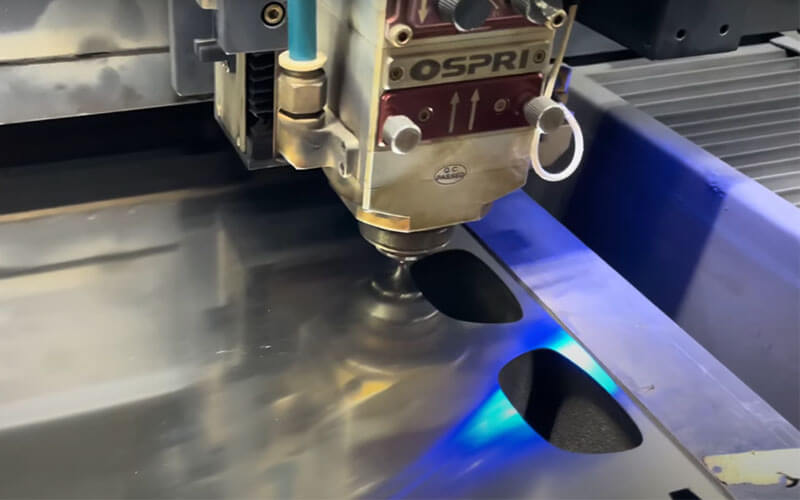

Forming and Processing Techniques for Titanium Eyewear

The forming process for titanium eyewear typically involves stamping, extrusion, or laser cutting, which precisely controls the shape and dimensions of the frames, ensuring accuracy and consistency. During processing, titanium undergoes multiple heat treatments to enhance strength and durability. Finally, titanium eyewear frames undergo surface treatments such as polishing, electroplating, or spraying to improve appearance and protective performance.

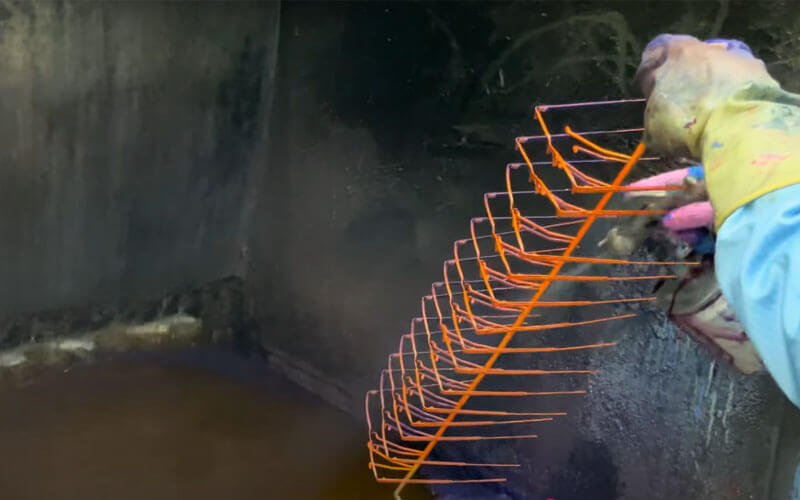

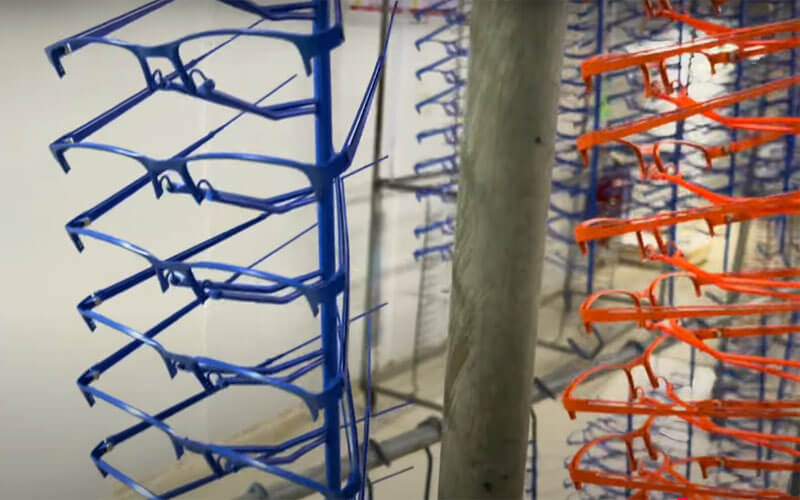

Surface Treatment Techniques for Titanium Eyewear

Surface treatment is crucial for titanium eyewear, with common methods including anodizing, electroplating, and spraying. Anodizing forms a protective oxide layer on the titanium surface, enhancing corrosion resistance and creating unique color effects. Electroplating further enhances the gloss and wear resistance of titanium eyewear, while spraying offers various color and texture effects, making the product more competitive in the market.

| Surface Treatment Technique | Main Function | Achieved Effects |

| Anodizing | Forms a protective layer, enhances corrosion resistance | Provides various color options, improves corrosion resistance |

| Electroplating | Enhances gloss and wear resistance, protects the metal surface | Increases gloss, improves durability |

| Spraying | Provides diverse color and texture effects, enhances aesthetics and customization | Offers a wide range of colors and textures, improves market competitiveness |

3. Design and Style of Titanium Eyewear

Combination of Modern and Classic Design

Titanium eyewear is well-suited for a blend of modern and classic design due to its material properties. Designers can leverage titanium’s thinness to create simple yet stable eyewear styles that meet various aesthetic preferences. The high strength of titanium allows designers to create bold and innovative designs without compromising frame stability.

Color and Texture Choices for Titanium

-

Fashion Titanium Eyeglasses Wholesaler – Atomic

$90.00 Select options This product has multiple variants. The options may be chosen on the product page -

Vintage Titanium Eyeglasses Wholesale Suppliers – 80984

$90.00 Select options This product has multiple variants. The options may be chosen on the product page -

Wholesale Highend Titanium Eyeglasses Frames – 10518

$90.00 Select options This product has multiple variants. The options may be chosen on the product page -

Wholesale Highend Titanium Glasses Frames – 202316

$90.00 Select options This product has multiple variants. The options may be chosen on the product page

Titanium naturally has a metallic sheen, but various surface treatments can produce a wide range of colors and textures. Anodizing can impart multiple color options to titanium eyewear, while polishing and spraying techniques can create matte, silky, or high-gloss finishes. These diverse color and texture options enable titanium eyewear to suit various occasions, from business to casual.

Application of Titanium Eyewear in the High-End Market

Due to the superior performance and higher manufacturing costs of titanium, titanium eyewear is typically positioned in the high-end market. High-end consumers value the comfort and durability of titanium eyewear, as well as its brand and design. Many luxury brands use titanium to create limited-edition or custom eyewear to meet the needs of consumers seeking quality and uniqueness.

Design for Different Consumer Groups

Titanium eyewear, with its diverse designs and high performance, meets the needs of various consumer groups. For business professionals, titanium eyewear offers stable, classic designs and comfort for extended wear. For younger consumers, titanium eyewear can attract attention with its wide range of colors and stylish designs. Additionally, titanium’s lightweight property makes it an ideal choice for sports enthusiasts.

Receive Custom Guidance

Looking for the perfect custom eyewear to represent your brand?

Reach out to Eyewearbeyond for expert guidance on choosing the best materials, styles, and customizations for your eyewear collection!

4. Performance and Durability of Titanium Eyewear

Resistance to Deformation

Titanium’s high strength ensures that titanium eyewear does not easily deform during daily use, maintaining the shape and structure of the frames over time. This feature not only enhances the durability of the eyewear but also ensures the stability of the fit, preventing discomfort caused by deformation.

Hypoallergenic Properties

Titanium is biocompatible and does not cause allergic reactions, making titanium eyewear particularly suitable for consumers with sensitive skin or allergies. Compared to other metals, titanium is more skin-friendly and can be worn with confidence.

Comfort for Long-Term Wear

The lightweight nature of titanium eyewear ensures that it places minimal burden on the nose and ears, even when worn for extended periods. This comfort is especially important for consumers who need to wear glasses all day. Additionally, the high strength of titanium allows manufacturers to design thinner and lighter frames, further enhancing the wearing experience.

Durability and Lifespan

Titanium eyewear excels in durability, maintaining its performance and appearance in various environments. Whether in high-temperature, humid, or acidic conditions, titanium eyewear remains resistant to deformation and rust, significantly extending the product’s lifespan. For consumers who value long-term product use, titanium eyewear is a wise investment.

| Performance Dimension | Advantages of Titanium | Application Scenarios |

| Deformation Resistance | High strength prevents deformation, maintaining stability | Daily use, sportswear |

| Hypoallergenic Properties | Non-toxic, does not cause allergic reactions | Suitable for sensitive skin, consumers with allergies |

| Comfort | Lightweight and comfortable, no burden during long-term wear | Long-term wear needs |

| Durability | Corrosion-resistant, wear-resistant, long lifespan | Long-term use in various environments |

5. Environmental Sustainability of Titanium

Recyclability of Titanium

Titanium is highly recyclable, reducing the consumption of natural resources when recycled after disposal. The recycling process for titanium is relatively simple and environmentally friendly, allowing titanium eyewear to be recycled at the end of its lifecycle with minimal environmental impact, aligning with sustainability principles.

Environmental Impact of Production

Although titanium refining and processing are complex, modern technologies have significantly reduced their environmental impact. Titanium production involves fewer harmful chemicals, and production waste can be recycled. Additionally, the long lifespan and durability of titanium reduce the environmental burden associated with frequent product replacement.

Lifecycle Analysis of Titanium Eyewear

The lifecycle of titanium eyewear is generally long, and it demonstrates good environmental performance at every stage, from production to disposal. Its durability and recyclability result in a lower overall environmental impact compared to eyewear made from other metal materials. For environmentally conscious consumers, titanium eyewear is undoubtedly a more sustainable choice.

| Environmental Dimension | Advantages of Titanium | Application Scenarios |

| Recyclability | High recyclability reduces natural resource consumption | Suitable for environmentally conscious consumers |

| Environmentally Friendly Production | Uses fewer harmful chemicals, and waste is recyclable | Sustainable production processes |

| Lifecycle | Long lifespan and durability reduce replacement frequency, lowering environmental impact | Consumers seeking long-term product value |

6. Market and Future Trends of Titanium Eyewear

Market Demand and Growth Trends for Titanium Eyewear

As consumers increasingly seek high quality, comfort, and durability, the market demand for titanium eyewear continues to grow. Titanium eyewear, known for its unique performance and stylish design, is becoming a popular choice in the high-end market. Simultaneously, as manufacturing processes improve and costs decrease, the penetration of titanium eyewear into the mid-range market is also increasing. It is expected that in the coming years, the market share of titanium eyewear will expand further.

Application Prospects of Titanium in Future Eyewear Design

With technological advancements, titanium is expected to play a larger role in eyewear design. For example, the demand for lightweight and high-strength materials in smart eyewear makes titanium an ideal choice. Additionally, the combination of titanium with other new materials, such as carbon fiber or ceramics, will further enhance the performance and design possibilities of eyewear.

Integration of Smart Eyewear with Titanium

As smart technology advances, smart eyewear is becoming increasingly popular. Titanium, due to its lightweight, durability, and biocompatibility, is an ideal material for manufacturing smart eyewear. Titanium not only meets the weight and strength requirements of smart eyewear but also seamlessly integrates with electronic components through advanced processing techniques, enhancing the overall performance and wearing experience of smart eyewear.

Development of High-Tech Coatings and Surface Treatments

In the future, titanium eyewear will increasingly utilize high-tech coatings and surface treatments. New coatings can provide titanium eyewear with enhanced scratch resistance, fingerprint resistance, and anti-reflective properties, improving both practicality and visual appeal. Additionally, with the development of nanotechnology, the surface treatment of titanium eyewear will become more refined and intelligent, further enhancing the product’s added value.

7. Pricing and Consumer Choices for Titanium Eyewear

Pricing Factors for Titanium Eyewear

The price of titanium eyewear is mainly influenced by material costs, manufacturing processes, and brand positioning. The refining and processing costs of titanium are high, resulting in titanium eyewear generally being priced higher than other metal eyewear in the market. Additionally, titanium eyewear often employs more complex manufacturing processes, such as laser cutting and anodizing, which also increase production costs. However, with the advancement of technology and the expansion of the market, the price of titanium eyewear is expected to gradually decrease, making it accessible to a broader consumer base.

Consumer Demand and Preferences for Titanium Eyewear

Consumer demand for titanium eyewear is primarily concentrated in the high-end market. Still, as titanium becomes more widespread and prices decrease, more mid-range consumers are starting to take an interest in titanium eyewear. The main reasons consumers choose titanium eyewear include its lightweight, comfort, durability, and hypoallergenic properties. Furthermore, the diverse designs and color options of titanium eyewear meet consumers’ demands for fashion and individuality.

Cost-Effectiveness and Market Positioning of Titanium Eyewear

Although titanium eyewear is priced higher, its durability and comfort give it a certain advantage in terms of cost-effectiveness. For consumers who prioritize product quality and long-term value, titanium eyewear is a wise choice. As the market matures and production costs decrease, titanium eyewear is expected to capture a larger market share in the future, becoming a mainstream product among metal eyewear.

8. Conclusion

With its unique properties of lightweight, high strength, corrosion resistance, and biocompatibility, titanium has secured an important place in metal eyewear manufacturing. Titanium eyewear not only excels in the high-end market but is also gradually making its mark in the mid-range market. As technology advances and market demand grows, titanium has promising prospects in eyewear design. In the future, titanium eyewear will continue to evolve through the integration of smart technology and high-tech coatings, offering consumers a higher-quality wearing experience and more diverse choices.

Here are some frequently asked questions (FAQs) related to the application of titanium in metal eyewear:

1. What makes titanium a popular choice for metal eyewear?

Answer:

Titanium is popular for metal eyewear due to its lightweight, high strength, corrosion resistance, and hypoallergenic properties. These characteristics make titanium eyewear comfortable for long-term wear, durable, and safe for people with sensitive skin or allergies.

2. How does titanium compare to other metals used in eyewear?

Answer:

Compared to other metals like stainless steel and aluminum, titanium is significantly lighter and stronger. It offers superior corrosion resistance, making it ideal for use in humid environments. Additionally, titanium is hypoallergenic, whereas other metals may cause skin irritation or allergies in some individuals.

3. Is titanium eyewear suitable for people with sensitive skin?

Answer:

Yes, titanium is biocompatible and does not cause allergic reactions, making it an excellent choice for people with sensitive skin or those prone to metal allergies.

4. How durable is titanium eyewear?

Answer:

Titanium eyewear is highly durable, offering excellent resistance to deformation, corrosion, and wear. It performs well in various environments, including high temperatures and humid conditions, ensuring a long lifespan.

5. What are the different types of titanium alloys used in eyewear, and how do they differ?

Answer:

Common titanium alloys used in eyewear include:

- TA1 (Pure Titanium): High titanium content (≥99.5%), offering lightweight and excellent corrosion resistance, often used in high-end eyewear.

- TC4 (Titanium Alloy): A combination of titanium with aluminum and vanadium, known for its high strength and good workability, suitable for complex frame designs.

- TB5 (Titanium Alloy): Includes titanium, aluminum, vanadium, and molybdenum, providing extremely high tensile strength and fatigue resistance, ideal for professional sports eyewear.

6. What surface treatments are available for titanium eyewear?

Answer:

Surface treatments for titanium eyewear include:

- Anodizing: Adds a protective oxide layer, enhances corrosion resistance, and allows for various color options.

- Electroplating: Increases gloss and wear resistance, giving the eyewear a polished, durable finish.

- Spraying: Provides a wide range of color and texture effects, enhancing aesthetics and customization.

7. Is titanium eyewear more expensive than other metal eyewear?

Answer:

Yes, titanium eyewear is generally more expensive due to the higher cost of titanium materials and the complex manufacturing processes involved. However, its durability, comfort, and hypoallergenic properties often justify the higher price for many consumers.

8. How does titanium contribute to sustainable eyewear manufacturing?

Answer:

Titanium is highly recyclable, reducing the consumption of natural resources. The production process involves fewer harmful chemicals, and its long lifespan reduces the need for frequent replacements, resulting in a lower overall environmental impact.

9. Is titanium eyewear suitable for sports and outdoor activities?

Answer:

Yes, titanium’s high strength and lightweight properties make it ideal for sports and outdoor activities. It resists deformation and damage, even under stress, and remains comfortable to wear during physical activities.

10. What future trends can we expect in the use of titanium in eyewear?

Answer:

Future trends include the increased integration of titanium in smart eyewear, where its lightweight and durable properties are essential. Additionally, advancements in surface treatments and coatings will further enhance the performance and aesthetics of titanium eyewear, making it even more appealing to a broader market.

Request a Free Quote

Wondering how to budget for your custom eyewear order?

Contact us to receive a tailored quote designed specifically for your eyewear needs!