In the modern eyewear manufacturing industry, metal eyewear is highly favored for its durability and fashionable versatility. To further enhance the aesthetics and market competitiveness of metal eyewear, spray painting technology has become an indispensable process. Spray painting not only provides a wide range of color options for metal eyewear but also achieves diverse surface textures through special techniques, meeting consumers’ demand for personalization and style. This article will explore the application of spray painting technology in metal eyewear manufacturing in detail, from basic principles to future developments, showcasing the core value of this process.

2. Basic Principles of Spray Painting Technology

Overview of Spray Painting Process

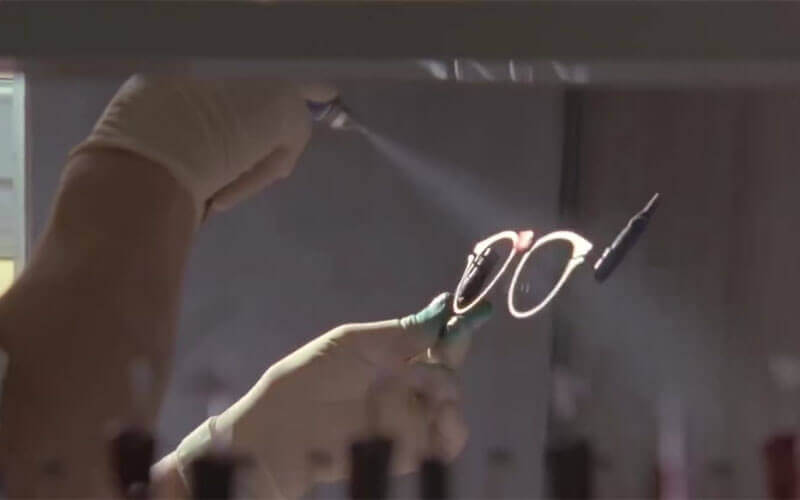

Spray painting is a technique that involves applying paint evenly to the surface of metal using compressed air or other gases to spray the paint through a spray gun. By layering multiple coats, the desired color and texture are achieved. The key to spray painting lies in its ability to cover surfaces with various colors while enhancing the metal’s natural sheen, thereby increasing the product’s visual appeal.

Common Spray Painting Materials and Equipment

The choice of spray painting materials determines the final color effect and coating performance. Below is a table describing some common spray painting materials and their application scenarios:

| Spray Painting Material | Characteristics | Application Scenarios |

| Metallic Paint | Provides surface gloss and metallic texture | High-end eyewear products, adds luxury appeal |

| Plastic Paint | Offers a variety of colors, versatile textures | Fashionable eyewear, suitable for young consumers |

| Powder Coating | High wear resistance, environmentally friendly | Business eyewear, improves durability and lifespan |

| Water-based Paint | Low VOC emissions, excellent environmental performance | Meets demands for eco-friendly and healthy products |

Metallic Paint

Plastic Paint

Powder Coating

Water-based Paint

These materials, used in conjunction with equipment such as spray guns, air compressors, and paint heaters, can achieve a variety of coating effects ranging from matte to high gloss, and from solid colors to gradients.

Steps and Processes of Spray Painting

The spray painting process typically involves the following key steps:

- Pre-treatment: Cleaning, sanding, and degreasing the metal surface to ensure paint adhesion.

- Primer Application: Applying a primer as the first coat to enhance the adhesion and durability of subsequent paint layers.

- Color Application: Applying color coats according to design requirements, layering them to achieve the desired effect.

- Curing: Baking or air-drying the coated eyewear to harden the paint and ensure it adheres firmly to the metal surface.

- Topcoat Application: Applying a clear topcoat to increase surface gloss and wear resistance.

Each step is crucial to the final outcome, requiring precise control of details to ensure color uniformity and coating durability.

3. Application of Spray Painting in Metal Eyewear Manufacturing

The Role of Spray Painting in Surface Treatment of Eyewear

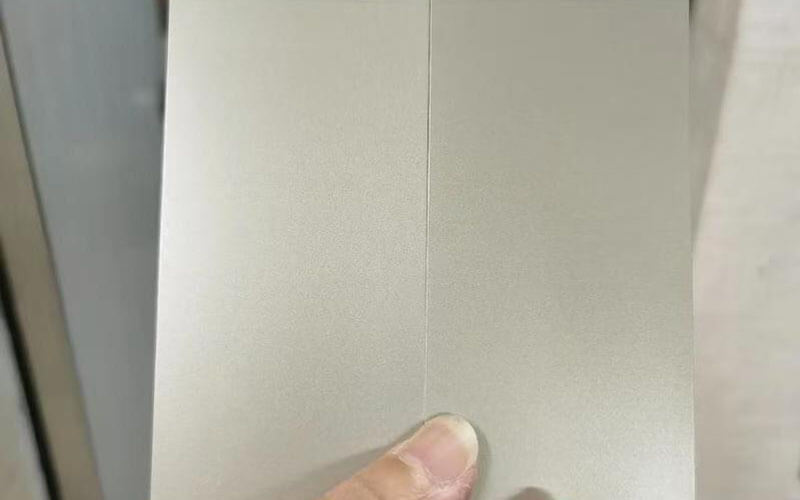

Spray painting technology is a key step in the surface treatment of metal eyewear. Through spray painting, eyewear frames can be endowed with various vibrant colors and different texture effects, such as matte, glossy, or silky finishes. Spray painting enables eyewear designers to quickly adapt product appearances according to market trends and consumer demands, making metal eyewear more competitive in the market.

Common Spray Painting Effects and Their Application Scenarios

Spray painting technology can achieve various color and surface effects to suit different application scenarios. Below is a description of common spray painting effects and their application scenarios:

| Spray Painting Effect | Characteristics | Application Scenarios |

| Matte Effect | Low surface gloss, presenting a soft texture | Suitable for understated luxury business style, favored by mature consumers |

| Glossy Effect | High gloss, mirror-like smooth surface | High-end fashion eyewear, appealing to image-conscious young consumers |

| Gradient Effect | Colors transition smoothly from dark to light | Personalized, trendy products, meeting the needs of fashion-forward consumers |

| Special Texture | Surface features unique tactile and visual effects | High-end custom eyewear, providing a unique user experience |

Matte Effect

Glossy Effect

Gradient Effect

Special Texture

These effects not only enrich the design language of the product but also enhance the consumer’s visual experience, increasing the appeal of the eyewear.

Combining Spray Painting with Other Surface Treatment Techniques

Spray painting can be combined with other surface treatment techniques to create more complex and unique visual effects. For example, spray painting after electroplating allows the metallic tones to complement the spray colors, adding depth to the product’s color palette. Spray painting after brushing treatment can maintain the fine texture of the metal surface while adding new color dimensions, making the product more sophisticated and stylish.

4. Impact of Spray Painting on the Appearance of Metal Eyewear

Enhancing the Color Richness and Saturation of Metal Eyewear

Spray painting significantly enhances the color richness and saturation of metal eyewear, making the eyewear appear more vibrant and long-lasting. Compared to traditional electroplating and oxidation processes, spray painting provides higher color saturation, especially when highlighting brand identity or expressing specific design concepts.

Through spray painting, designers can choose single tones or multi-color combinations, even achieving complex gradient effects on a single surface. This makes metal eyewear visually richer and more diverse, meeting the market’s demand for personalized products.

Achieving Matte, Glossy, and Gradient Effects with Spray Painting

Spray painting technology can flexibly achieve various texture effects. For example, matte spray painting reduces surface reflection, making eyewear appear understated yet tasteful, ideal for business professionals or consumers who prefer a reserved style. Glossy spray painting gives eyewear a shiny appearance, suitable for designs that need to attract attention. Gradient spray painting, through multiple applications and layering, creates a natural transition from dark to light, adding depth and visual impact to the product.

How Spray Painting Meets Different Market Demands and Consumer Preferences

Different markets and consumers have varying preferences for the color and texture of eyewear. Younger consumers tend to favor bold, vibrant colors, while mature consumers prefer low-key, neutral tones. The versatility of spray painting allows eyewear manufacturers to flexibly respond to these demands, customizing products for different markets. Additionally, the ability of spray painting to quickly adapt to market trends enables brands to launch new products that align with current trends, increasing market responsiveness.

-

Bulk Buy Metal Eyewear – 3062

$80.00 Select options This product has multiple variants. The options may be chosen on the product page -

Bulk Wholesale Metal Eyewear – HT004

$80.00 Select options This product has multiple variants. The options may be chosen on the product page -

Buy Metal Eyewear in Bulk – 3096

$80.00 Select options This product has multiple variants. The options may be chosen on the product page -

Wholesale Highend Metal Eyewear – 1988

$99.00 Select options This product has multiple variants. The options may be chosen on the product page

5. Quality Control in the Spray Painting Process

Methods for Controlling the Uniformity and Adhesion of Spray Paint

Uniformity and adhesion are two key quality indicators in the spray painting process. To ensure even color distribution, the speed and angle of the spray gun must be precisely controlled during application to avoid uneven color or blotches. Additionally, surface preparation (e.g., cleaning, sanding) before painting directly affects the adhesion of the coating. Only when the metal surface is free from oil and oxidation can the coating adhere evenly and firmly.

Wear Resistance and Corrosion Resistance Testing of the Spray Coating

To ensure the long-term durability of the spray coating, wear resistance and corrosion resistance tests are essential. Wear resistance is typically tested through abrasion tests, simulating everyday wear and ensuring the coating does not peel or scratch easily. Corrosion resistance is tested using salt spray tests, assessing the coating’s ability to withstand high humidity and saline environments. These test results help ensure the stability and durability of the spray coating in different environments.

Key Indicators and Standards for Spray Painting Quality Inspection

Quality inspection of spray painting needs to consider multiple factors, including color consistency, surface smoothness, coating adhesion, and wear and corrosion resistance. The table below shows the key indicators for spray painting quality inspection and corresponding standards:

| Inspection Indicator | Standard Description | Inspection Method |

| Color Consistency | No significant color difference, meets design requirements | Visual inspection or colorimeter measurement |

| Surface Smoothness | No noticeable particles, bubbles, or spots, moderate gloss | Visual inspection, gloss meter measurement |

| Coating Adhesion | No peeling or cracking, strong adhesion | Scratch test or tape peel test |

| Wear Resistance | No significant wear or scratches after abrasion test | Abrasion test |

| Corrosion Resistance | No noticeable corrosion spots or discoloration after salt spray test | Salt spray test |

By adhering to these strict inspection standards, manufacturers can ensure that spray-painted eyewear meets market requirements in terms of both appearance and performance, delivering high-quality products.

6. Advantages of Spray Painting in Customized Production

Flexibility and Customizability of Spray Painting Technology

The high flexibility of spray painting technology provides unique advantages in customized production. Brands can tailor unique color combinations or surface textures to meet the personalized needs of different markets and consumers. For example, limited-edition products designed for specific customer groups can be quickly realized through spray painting, enhancing the brand’s market competitiveness and product added value.

Application of Spray Painting Technology in Small-batch Production

In small-batch production, the flexibility of spray painting technology is particularly crucial. Compared to other surface treatment methods, spray painting can quickly adjust colors and effects, making it suitable for the production of limited-edition and customized products. Especially in response to rapidly changing market trends, spray painting technology enables brands to quickly launch new products that align with current trends, effectively improving market responsiveness.

The Role of Spray Painting in Brand Differentiation

Spray painting technology provides brands with tools for differentiation in design. Through unique color and texture designs, brands can stand out in a competitive market. For example, brands can use spray painting technology to achieve gradient or dual-color effects, enhancing the visual impact of products and increasing brand recognition. In the market, consumers are often more interested in products with unique appearances and textures, making spray painting technology an essential means for brands to build a unique image.

7. Environmental and Health Considerations of Spray Painting

Environmental Performance of Spray Painting Materials and Their Selection

With increasing environmental awareness, the environmental performance of spray painting materials has become a key criterion for manufacturers. Modern spray painting technology increasingly adopts low-VOC (volatile organic compounds) or VOC-free water-based paints to reduce environmental pollution. Water-based paints not only have good environmental performance but also provide color performance and durability comparable to traditional solvent-based paints. Additionally, using eco-friendly materials helps enhance a brand’s social responsibility, aligning with the market’s current demand for green products.

Controlling Volatile Organic Compounds (VOC) During Spray Painting

VOC emissions are a major environmental concern during the spray painting process, posing potential hazards to both the environment and health. To reduce VOC emissions, manufacturers can take the following measures:

- Choose low-VOC or VOC-free eco-friendly paints.

- Equip advanced ventilation systems to promptly expel harmful gases.

- Use automated spray painting equipment to improve paint utilization and reduce waste.

These measures enable manufacturers to effectively control VOC emissions during the spray painting process, reducing environmental impact and protecting workers’ health.

Health Impact and Safety Standards of Spray Painting for Wearers

To ensure that spray-painted eyewear is safe for wearers, manufacturers must comply with strict safety standards. For example, the EU’s RoHS directive and REACH regulations impose strict limits on harmful substances in eyewear products. Spray painting materials must not contain harmful heavy metals such as nickel or lead, and the coatings must undergo rigorous testing to ensure they do not cause skin allergies or other health issues. Below are some common safety testing standards:

| Safety Testing Standard | Testing Content | Objective |

| RoHS Directive | Limits on the content of harmful substances in products | Ensures no harmful heavy metals, such as nickel or lead |

| REACH Regulation | Registration, evaluation, authorization, and restriction of chemicals | Controls the use of chemicals to protect human health and the environment |

| Nickel Release Test | Tests the amount of nickel released from coatings | Prevents nickel-induced skin allergic reactions |

| Skin Sensitivity Test | Evaluates the irritation of the coating to the skin | Ensures wearer’s skin safety, no allergic reactions |

By strictly adhering to these standards, spray-painted eyewear not only provides excellent visual effects but also ensures the health and safety of the wearer.

8. Future Development Trends in Spray Painting Technology

Innovative Applications of Spray Painting Technology in the Eyewear Industry

As technology advances, spray painting technology will be more widely and innovatively applied in the eyewear industry. In the future, spray painting technology will focus more on intelligence and environmental protection. For example, intelligent spray painting technology can be computer-controlled, achieving more precise and complex color gradients and texture effects. Additionally, nano spray painting technology will gradually be applied in eyewear manufacturing, giving products finer surface textures and higher durability.

Integration of Spray Painting with Smart Manufacturing

The development of smart manufacturing technology offers new possibilities for optimizing the spray painting process. Through intelligent production lines, manufacturers can achieve real-time monitoring and precise control of the spray painting process, ensuring consistency in every production stage. By combining IoT (Internet of Things) technology, manufacturers can monitor paint composition, spray thickness, and curing temperature in real time, automatically adjusting spray parameters to achieve optimal effects. This not only improves production efficiency but also significantly reduces defect rates and material waste.

Environmental Improvements in Spray Painting Technology

In the future, environmental protection will be a key direction in the development of spray painting technology. As regulations become stricter and consumer awareness of environmental protection increases, manufacturers will focus more on developing and using eco-friendly spray painting materials, such as water-based paints and biodegradable coatings. These materials not only reduce VOC emissions but also minimize environmental impact at the end of their lifecycle. Additionally, the development of paint waste recycling technology will further promote the sustainability of the spray painting process.

9. Conclusion and Outlook

The application of spray painting technology in metal eyewear manufacturing provides strong support for product design and market competitiveness. Through spray painting, metal eyewear can not only present rich colors and textures but also meet the diverse needs of consumers through various surface treatments. In the future, with continuous advancements in smart manufacturing and environmental technology, spray painting will play a greater role in eyewear design and production. Brands should actively adopt spray painting technology, continuously innovate, and enhance their competitive advantage in the market. In future developments, spray painting technology will not only become more refined and intelligent but also achieve greater progress in environmental protection and sustainability.

Here are some frequently asked questions (FAQs) related to the application of spray painting in metal eyewear manufacturing:

1. What is spray painting, and why is it important in metal eyewear manufacturing?

Answer:

Spray painting is a process that involves applying paint to the surface of metal eyewear using compressed air or other gases to achieve a smooth, even coating. This technique is crucial in metal eyewear manufacturing because it allows for a wide range of color and texture options, enhancing the visual appeal and marketability of the eyewear. It also enables manufacturers to customize products to meet specific consumer preferences and market trends.

2. What materials are commonly used in spray painting for metal eyewear?

Answer:

Common materials used in spray painting for metal eyewear include metallic paints, plastic paints, powder coatings, and water-based paints. Each material offers different properties:

- Metallic Paints: Provide a glossy, metallic finish, often used in high-end eyewear.

- Plastic Paints: Versatile in color, suitable for fashion-oriented designs.

- Powder Coatings: Highly durable, environmentally friendly, and ideal for business eyewear.

- Water-based Paints: Low VOC emissions, making them eco-friendly and suitable for health-conscious consumers.

3. How does spray painting improve the appearance of metal eyewear?

Answer:

Spray painting enhances the appearance of metal eyewear by providing vibrant colors, varied textures, and high-quality finishes. It allows manufacturers to create glossy, matte, or gradient effects, adding depth and richness to the product’s design. Spray painting also enables the creation of special textures that can make eyewear look more sophisticated and unique, catering to different style preferences and market demands.

4. Can spray painting be combined with other surface treatments?

Answer:

Yes, spray painting can be effectively combined with other surface treatments like electroplating, brushing, or polishing. For example, after electroplating, a spray-painted layer can add color depth and contrast, creating a more dynamic visual effect. Similarly, spray painting after brushing can retain the metal’s texture while introducing new color dimensions, enhancing the overall design and appeal of the eyewear.

5. What are the key factors to ensure high-quality spray painting?

Answer:

To ensure high-quality spray painting, manufacturers must focus on:

- Uniformity: Achieving even color distribution by precisely controlling the spray gun’s movement and paint application.

- Adhesion: Ensuring strong paint adhesion by thoroughly cleaning and preparing the metal surface before painting.

- Durability: Testing the coating for wear resistance and corrosion resistance to ensure long-lasting quality.

- Consistency: Maintaining consistent color and finish across all products by adhering to strict quality control standards.

6. How does spray painting contribute to customized production?

Answer:

Spray painting offers significant flexibility and customization options, making it ideal for producing limited-edition or personalized eyewear. Manufacturers can quickly adjust colors and textures to meet specific customer demands, allowing brands to offer unique products that stand out in the market. This adaptability is particularly valuable in small-batch production, where responsiveness to market trends is crucial.

7. Is spray painting environmentally friendly?

Answer:

Spray painting can be environmentally friendly, especially when using water-based paints or low-VOC (volatile organic compound) paints. These eco-friendly options reduce harmful emissions and minimize the environmental impact of the manufacturing process. Additionally, manufacturers can further reduce environmental impact by using advanced ventilation systems to control VOC emissions and by recycling paint waste.

8. How does spray painting affect the health and safety of eyewear users?

Answer:

To ensure the safety of eyewear users, spray-painted products must comply with strict safety standards, such as the EU’s RoHS and REACH regulations. These standards limit the use of harmful substances like heavy metals in paint. Spray painting materials must undergo rigorous testing, such as nickel release tests, to ensure they do not cause skin allergies or other health issues. By following these guidelines, manufacturers can produce safe, skin-friendly eyewear.

9. What are the future trends in spray painting technology for eyewear?

Answer:

Future trends in spray painting technology for eyewear include the integration of intelligent manufacturing techniques and the development of more eco-friendly materials. Intelligent spray painting systems can offer precise control over color gradients and textures, enabling more complex and innovative designs. Additionally, the use of water-based and biodegradable paints will continue to grow as manufacturers prioritize sustainability and environmental responsibility.

10. How can spray painting help a brand differentiate itself in the eyewear market?

Answer:

Spray painting allows brands to create unique and visually striking designs that set them apart from competitors. By offering custom colors, textures, and effects—such as gradients or special finishes—brands can develop a distinctive visual identity that appeals to specific consumer groups. This differentiation helps build brand recognition and loyalty, making spray painting a valuable tool in a brand’s design and marketing strategy.

Receive Custom Guidance

Looking for the perfect custom eyewear to represent your brand?

Reach out to Eyewearbeyond for expert guidance on choosing the best materials, styles, and customizations for your eyewear collection!