When it comes to producing high-performance sports eyewear, two dominant manufacturing techniques stand out: Injection Molding and Traditional Manufacturing (which includes manual cutting, CNC machining, and acetate lamination).

Each method has its strengths and limitations in terms of durability, cost, customization, production efficiency, and sustainability. Whether you’re an eyewear brand owner, wholesaler, or custom eyewear buyer, understanding these differences can help you select the best manufacturing approach for your business.

Let’s break down these two manufacturing processes in detail, analyzing their impact on performance, cost-effectiveness, and market positioning.

1. Understanding the Two Manufacturing Methods

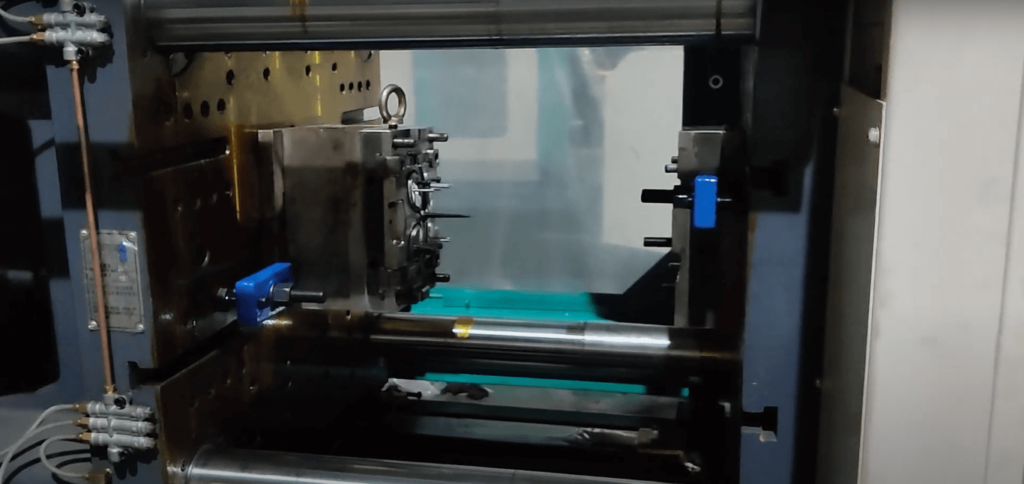

What is Injection Molding?

Injection molding is a high-precision, automated process that injects molten plastic into a pre-designed mold at high pressure. The material cools and solidifies, forming a lightweight yet durable eyewear frame. This method is particularly popular for sports eyewear, performance sunglasses, and industrial safety glasses, where impact resistance, flexibility, and consistency are essential.

- Speed & Efficiency: Each frame can be produced in under 60 seconds.

- High Consistency: Every piece is identical due to automated molding.

- Material Efficiency: Minimal waste and recyclable plastic options.

- Mass Customization: Various colors, textures, and logo branding options.

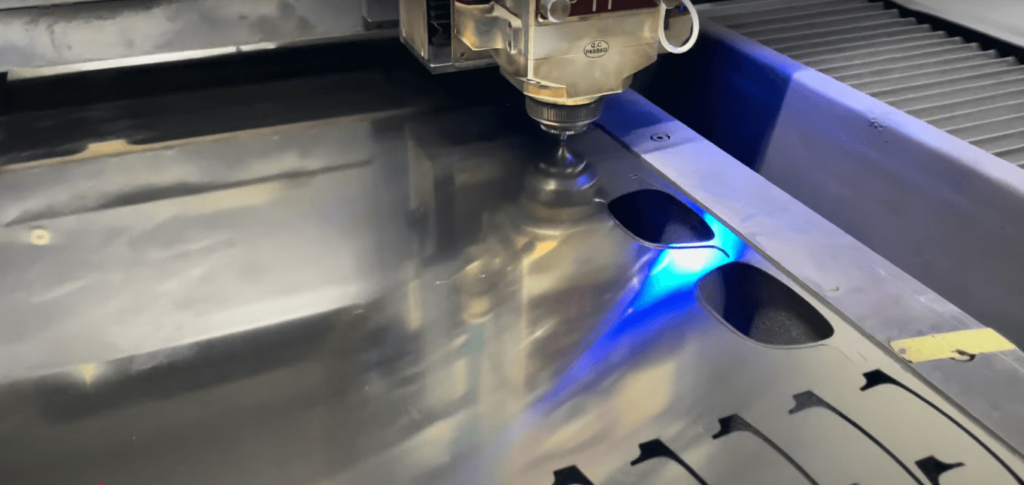

What is Traditional Manufacturing?

Traditional eyewear manufacturing relies on manual or CNC-based techniques where frames are cut, shaped, polished, and finished from solid acetate or metal sheets. This method is the foundation of premium handmade eyewear, acetate fashion frames, and luxury collections, emphasizing craftsmanship.

- Handcrafted Precision: Each frame undergoes multiple cutting, shaping, and polishing steps.

- Unique Finishes: Artisanal touch allows for intricate detailing, custom patterns, and layered color designs.

- Stronger but Less Flexible: Frames can be durable but are more prone to breakage under extreme impact.

2. Injection Molding vs. Traditional Manufacturing: A Detailed Comparison

| Feature | Injection Molding | Traditional Manufacturing |

|---|---|---|

| Production Speed | Fast – Frames molded in seconds | Slow – Multiple cutting, shaping, and finishing steps |

| Material Options | TR90, Nylon, Polycarbonate, TPU, TPE | Acetate, Metal, Titanium, Stainless Steel |

| Customization | Multi-color injection, engraved logos, rubber coatings | Handmade finishes, unique layered acetate colors |

| Durability | High impact resistance, lightweight, flexible | Rigid, premium feel but may crack under stress |

| Precision & Consistency | Extremely high – Every frame is identical | Medium – Slight variations due to manual processes |

| Best for | Sports eyewear, safety glasses, high-volume production | Luxury eyewear, boutique brands, limited editions |

| Production Cost | Lower for bulk orders due to automation | Higher due to labor-intensive processes |

3. Production Speed & Efficiency: Why Injection Molding is Superior

For brands looking to manufacture eyewear at scale, speed and efficiency are major factors.

- Injection Molding: Produces thousands of frames per day with minimal labor, keeping costs down.

- Traditional Manufacturing: Labor-intensive, requiring manual shaping, polishing, and finishing, leading to longer lead times and higher costs.

For high-volume production, injection molding is the clear winner. If you’re launching a sports eyewear brand and need bulk production with quick turnaround times, this method is your best choice.

4. Durability & Performance: Which Material is Stronger?

Sports eyewear needs to withstand extreme conditions, including high-impact activities, temperature changes, and outdoor exposure. Let’s compare how both methods hold up.

Injection Molding: Superior Impact Resistance

Frames made from TR90, Nylon, or Polycarbonate offer: ✔ High Flexibility – Absorbs impact without breaking

✔ Lightweight Comfort – Reduces pressure on the nose and ears

✔ Resistant to Heat & Moisture – Ideal for extreme environments

Traditional Manufacturing: Rigid but Luxurious

Frames made from acetate or metal provide: ✔ A Premium Look & Feel – Hand-polished, smooth surfaces

✔ Durability Over Time – Strong but heavier

✔ Less Flexible – More likely to crack under impact

For sports and safety eyewear, injection molding provides better shock absorption and durability.

5. Customization & Branding: Which Offers More Design Freedom?

Eyewear brands need distinctive, high-quality customization options to stand out.

Injection Molding: High Precision & Mass Customization

✔ Color Injection Technology – Gradient, translucent, and solid color designs

✔ Textured Finishes – Matte, glossy, rubberized coatings

✔ Laser-engraved Logos – Cost-effective branding on every frame

✔ Grip-Enhancing Rubber Coatings – Ideal for sports eyewear

Traditional Manufacturing: Artisanal Handcrafted Finishes

✔ Layered Acetate Colors – Unique patterns that injection molding cannot replicate

✔ Hand-Polished Finishes – Luxurious high-gloss or matte textures

✔ Metal Engravings – Suitable for boutique and luxury branding

If custom sports eyewear is your goal, injection molding provides cost-effective branding with consistent quality.

6. Cost Comparison: Which Method is More Affordable?

Cost is a key factor for both small brands and large-scale manufacturers.

- Injection Molding:

- High initial mold investment (~$3,000–$10,000 per mold)

- Low per-unit cost after mass production starts

- Best for high-volume production (OEM/ODM sports eyewear)

- Traditional Manufacturing:

- Labor-intensive, increasing production costs

- Expensive materials like acetate and titanium

- Best for small-batch, high-end collections

For large-scale production, injection molding is far more cost-effective.

7. Sustainability & Environmental Impact

With sustainability becoming a priority, let’s compare how each method affects the environment.

- Injection Molding

✔ Minimal material waste – Excess plastic can be recycled

✔ Energy-efficient – Lower overall environmental footprint

✔ Supports eco-friendly materials – Biodegradable plastics available - Traditional Manufacturing

❌ High material waste – Large amounts of acetate scraps

❌ Higher energy consumption – Requires multiple manual processes

For sustainable, large-scale eyewear production, injection molding is the greener option.

Choosing the Right Manufacturing Method

| Your Business Type | Best Choice |

|---|---|

| Sports eyewear brands needing mass production | Injection Molding |

| Safety eyewear manufacturers | Injection Molding |

| High-performance sports sunglasses brands | Injection Molding |

| Designer/luxury eyewear brands | Traditional Manufacturing |

| Boutique eyewear brands | Traditional Manufacturing |

| Brands focusing on sustainable eyewear | Injection Molding (with recycled materials) |

Final Thoughts: Which is Right for You?

If your goal is high-performance, impact-resistant sports eyewear in large quantities, injection molding is the superior choice due to its speed, efficiency, and cost-effectiveness.

However, if you’re targeting the luxury eyewear market, traditional manufacturing provides a handcrafted, artisanal aesthetic that appeals to premium buyers.