A Complete Guide to Top 60+ Luxury Sunglasses Brands Around the World 2025

Sunglasses have undergone a remarkable transformation—from being purely functional accessories designed to protect the eyes, to becoming iconic fashion statements. ...

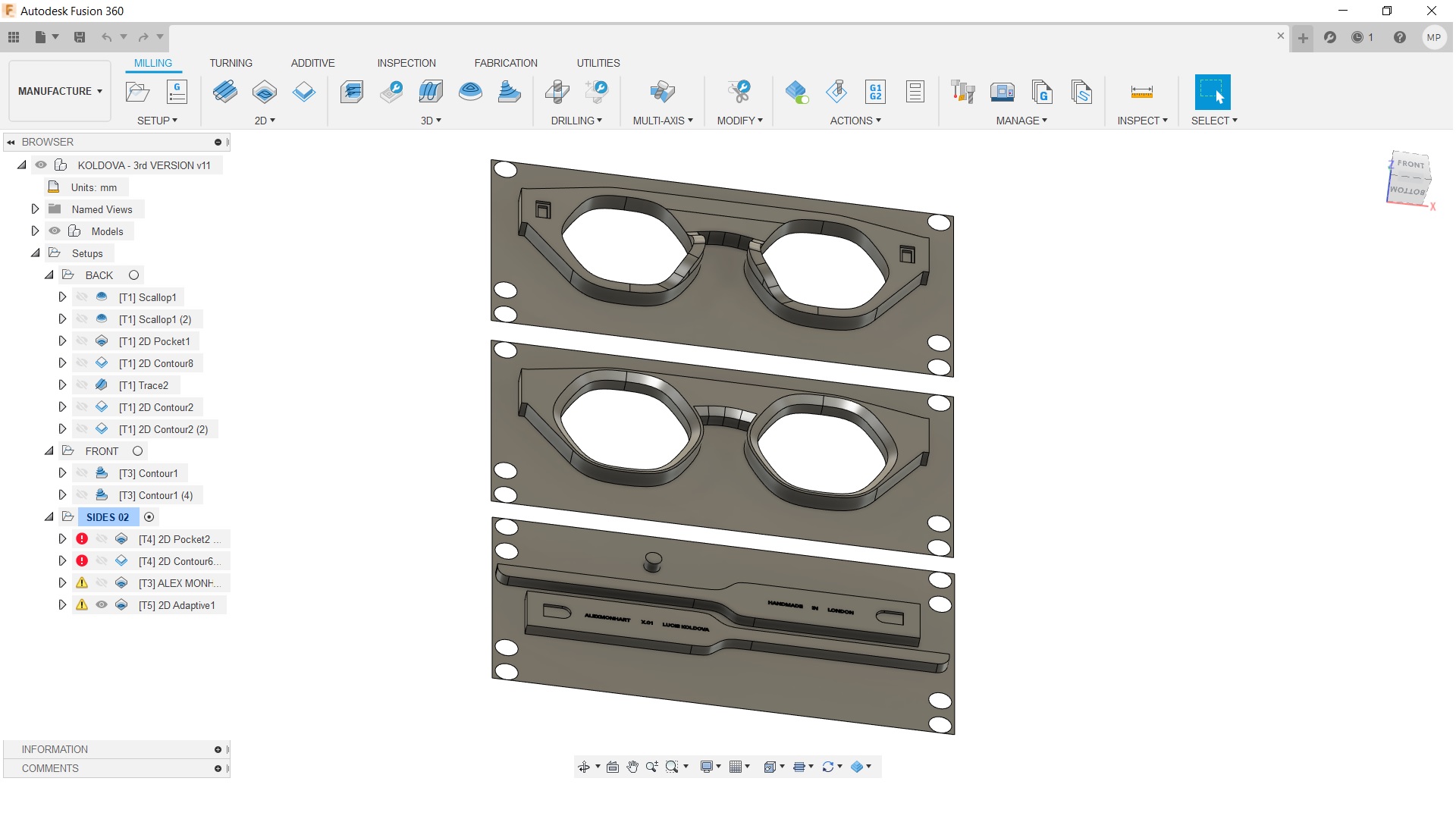

Our CNC Machining Solutions Deliver High-Precision Cutting for Eyewear Brands That Demand Flawless Fit and Finish.

In today’s fiercely competitive eyewear industry, design alone is no longer enough. Precision has become the true currency of premium eyewear brands.

It’s what determines whether a temple aligns flawlessly with a frame front, whether a nose bridge feels balanced on the face, and whether your end customer notices a refined product—or a flaw.

You may have invested in beautiful sketches, rich materials like titanium or Mazzucchelli acetate, and even strong branding. But if your manufacturer can’t translate those ideas into frame components that meet strict tolerances and consistent symmetry, your product will fall short—visually, functionally, and commercially.

At EyewearBeyond, we’ve been in the eyewear manufacturing business for over a decade. We’ve seen firsthand what happens when traditional cutting methods can’t keep up with modern design demands. That’s why we’ve built a dedicated CNC Machining Line—purpose-built for precision eyewear production, from minimalist optical frames to bold, sculpted statement pieces.

Whether you’re prototyping a new line or scaling to full production, our CNC line is designed to deliver:

✂️ Micron-level cutting accuracy (±0.005 mm)

🧱 Perfect repeatability across thousands of units

🧠 Freedom to design without compromise

Clean cuts. Balanced frames. Zero margin for error.

This is what your customers expect.

This is what EyewearBeyond delivers—every time.

CNC (Computer Numerical Control) is a digitally guided manufacturing method that cuts, drills, and shapes materials with machine-perfect accuracy. For eyewear brands, that means:

🔹 ±0.005 mm precision

🔹 Consistent frame symmetry across every batch

🔹 No molds required—ideal for small runs or new launches

🔹 Perfect for acetate, titanium, stainless steel, and even carbon fiber

This isn’t just production—it’s engineering that protects your design intent.

Frame fronts: full-rim, semi-rimless, or base cuts

Temples and temple tips

Titanium nose bridges and pad arms

Embedded hinge structures and metal cores

Laser-engraved logos and patterns

From minimalist metal eyewear to layered acetate showpieces, CNC helps you achieve form, function, and finish—at scale.

| Material | Why It Works in Eyewear |

|---|---|

| Titanium | Lightweight, corrosion-resistant, premium-grade appeal |

| Stainless Steel | Durable, cost-effective, classic business aesthetics |

| Acetate | Vibrant colors, easily milled, perfect for statement frames |

| Carbon Fiber | Ultra-strong and light, used in performance eyewear |

At EyewearBeyond, our CNC machining line is designed to serve eyewear brands with uncompromising precision, flexibility, and quality. Here’s a detailed breakdown of what our system can deliver:

| Feature | Specification & Value |

|---|---|

| Machine Type | 3-axis & 5-axis CNC milling Enables both flat and complex multi-dimensional cuts. Perfect for intricate temples, layered acetate fronts, and fine metal detailing. |

| Tolerance | ±0.005 mm (micron-level accuracy) Ensures perfect frame symmetry and snug component fit—critical for luxury-grade optical frames. |

| Max Frame Size | Up to 180 mm in length Supports full-size eyewear production, including oversized sunglasses or wrap-around sport styles. |

| File Formats Accepted | STEP, IGES, DXF, STL Compatible with most CAD software used by eyewear designers and engineers. We also support design file reviews before production. |

| Production Volume | From 1 prototype to 10,000+ units Ideal for both new brands launching small collections and larger companies scaling global production. |

| Turnaround Time | Samples in 5–7 business days Mass production in 2–4 weeks Fast, reliable lead times allow you to move from concept to market efficiently. |

✅ We use industrial-grade CNC equipment, German-standard tooling, and CNC-certified operators to ensure every cut is repeatable, clean, and aligned to your design specs—batch after batch.

Whether you’re machining lightweight titanium frames or colorful acetate temples, our CNC line delivers with consistency and speed.

Our CNC line is ideal for:

🕶️ Titanium optical frames with hidden components

🎨 Artistic acetate fronts with 3D relief or gradient cuts

💼 Business-ready minimalist styles needing frame balance

🚀 Start-up brand prototypes with fast turnaround

⚡ Hybrid metal-acetate builds with precise fit tolerances

Whatever the vision, CNC makes sure your design becomes wearable precision.

Want to turn your eyewear CAD files into market-ready frames with precision, speed, and reliability?

You’re in the right place.

Send your CAD file (STEP, DXF, IGES, or even sketches)

Choose your materials (metal or acetate)

Let us know quantity & delivery preferences

Get a custom quote within 1 business day

In the modern eyewear industry, design innovation means nothing without manufacturing precision. For brands creating high-end frames from titanium, stainless steel, or acetate, CNC milling offers the accuracy, repeatability, and design freedom needed to bring even the most intricate ideas to life.

Whether you’re producing custom optical frames, low-volume prototypes, or luxury sunglasses, CNC milling plays a foundational role in shaping high-quality eyewear components—without the need for expensive tooling.

In this article, we’ll explore:

What CNC milling really is

How the process works in frame production

Why it’s ideal for cutting metal and acetate

Key material insights specific to eyewear

Design tips for better CNC manufacturability

Let’s dive in.

CNC milling (Computer Numerical Control milling) is a digital machining method that uses rotating tools to cut, drill, and shape materials into a defined geometry—typically based on a 2D or 3D design file (CAD).

In eyewear manufacturing, CNC milling is used to produce:

Frame fronts (especially in acetate and titanium)

Temples and temple cores

Bridge components and nose pads

Custom-cut logos or engraving slots

Prototype parts with tight tolerances

Unlike molding or stamping, CNC milling doesn’t require dies or patterns. It provides a contactless, repeatable, and highly accurate method to process premium eyewear materials into production-ready parts.

The CNC process typically follows these three key stages:

Designers create a detailed 2D or 3D model of the eyewear part using CAD software (e.g., Rhino, SolidWorks, Fusion360). The design includes:

Dimensions and tolerances

Slot depth for hinges

Bridge curvature

Surface textures or engraving points

The CAD file is then imported into CAM software to generate G-code, which controls:

Tool paths

Cutting speed

Depth of cut

Axis movement

Spindle speed

The operator loads the raw material (block of acetate, titanium sheet, etc.), uploads the G-code, and begins the milling process. The machine cuts with ±0.005 mm accuracy, ideal for:

Lens groove fitting

Seamless symmetry

Repeating the same design across thousands of units

Used to flatten the frame front surface, especially on acetate blocks. Ideal before polishing or engraving.

Used for creating curved edges and outlines—such as around the lens area or temple tips.

Used to cut precise hinge slots, nose pad slots, or embedded metal core grooves in temples.

Each operation uses a different tool path and cutter type to match the complexity and shape of the component.

Lightweight, corrosion-resistant

Perfect for minimalist luxury frames

Ideal for laser engraving & surface finishing

Durable, cost-effective

Good for classic optical styles

Compatible with electroplating

Rich in color, easy to polish

Ideal for CNC contouring, cut-outs, and 3D milling

Used in fashion-forward or artistic designs

High-performance, ultra-light

Perfect for sports or innovation-forward frames

Note: Each material requires specific spindle speeds, tool types, and coolant methods. At EyewearBeyond, our CNC line is pre-calibrated for all these materials to ensure smooth processing and quality control.

Want to reduce cost, waste, and turnaround time? Here’s how to optimize your eyewear designs for CNC manufacturing:

Avoid unnecessary undercuts unless using 5-axis milling

Maintain consistent wall thickness in acetate frames

Use standard radius corners to match tooling sizes

Keep hinge slots accessible for cutter paths

Design in metric (mm) for CNC compatibility

We offer free DFM (design for manufacturability) checks on all incoming files—so your designs are ready before cutting begins.

| Component | CNC Role |

|---|---|

| Optical frame front | 3D shaping, slotting, bridge milling |

| Temple arms | Tapered profiling, logo engraving, slot milling |

| Nose pads & bridges | Small component machining |

| Engraving | Branding, serial codes, texture effects |

| Prototyping | One-off sample production in days |

🎯 Unmatched precision (±0.005 mm tolerance)

📐 Freedom to innovate with complex designs

🚀 Fast sample-to-production transition

🧱 Low MOQ-friendly — great for new collections

♻️ Supports sustainable materials like bio-acetate

🧰 No mold/tooling costs

CNC milling isn’t just a manufacturing trend—it’s a must-have for modern eyewear brands looking to balance precision, flexibility, and speed. From custom prototypes to mass production, CNC enables designers and engineers to bring bold concepts to life with confidence and consistency.

At EyewearBeyond, we combine technical expertise, high-end equipment, and industry knowledge to deliver CNC-cut eyewear parts that meet the highest global standards.

This blog series explores everything you need to know about CNC in eyewear manufacturing: from how it works, to how it transforms raw materials like titanium, acetate, and stainless steel into beautifully engineered eyewear components.

Whether you’re just learning about CNC or looking to scale your custom frame production, these posts will give you insider insights, expert tips, and real-world examples to help you stay competitive in an industry where every millimeter matters.

Sunglasses have undergone a remarkable transformation—from being purely functional accessories designed to protect the eyes, to becoming iconic fashion statements. ...

Creating a sunglasses brand is a fantastic idea. But knowing how to establish and grow a successful sunglasses brand in ...

In modern eyewear manufacturing, acetate eyewear has become a popular choice. Whether for fashion brands or custom eyewear, acetate is ...

When it comes to eyewear, metal frames are a go-to choice for anyone who loves a classic, timeless look. Whether ...

Acetate frames are well-loved in the eyewear industry for their lightweight, durable, and flexible nature. They’re not just practical but ...

Acetate, also known as cellulose acetate, is a type of plastic derived from natural sources like wood pulp and cotton ...

We are here to help you 7 days a week and respond within 24 hours. Plus, you can find most answers to your questions right on this page.

A: Absolutely. Our CNC machining line is fully equipped to process both metal materials (like titanium, stainless steel, and nickel-free alloys) and non-metal materials such as Italian acetate, bio-acetate, and carbon fiber. Each material is handled with the appropriate tool settings and cooling systems to ensure clean cuts, no burn marks, and precision shapes with tight tolerances.

A: We offer flexible MOQs to support startups and boutique brands. Our standard MOQ starts at 300 pieces per model, depending on the design complexity and materials involved. For prototyping or market testing, we also support single-unit samples under our rapid CNC development program.

A: Our typical turnaround time for CNC prototypes is 35–40 business days, assuming the design file is ready and approved. If post-processing (such as polishing or engraving) is requested, it may add 1–7 days. We prioritize fast sampling to help brands test the market or finalize design specs quickly.

A: Yes, we provide full post-CNC finishing services, including:

Mirror polishing (hand or machine)

Matte surface brushing

Sandblasting

Anodizing or IP electroplating (for metals)

Laser engraving for logos or design detailing

Logo stamping or silk screen printing (for acetate)

This makes your parts not only precise—but also retail-ready.

A: We accept most industry-standard CAD files, including STEP (.stp), IGES (.igs), DXF (.dxf), and STL (.stl). If you only have 2D sketches or conceptual designs, our engineering team can help convert them into CNC-ready files.

A: Our facility uses both 3-axis and 5-axis CNC milling machines. 3-axis machines are perfect for standard component shaping (like flat temple arms), while 5-axis machines enable multi-dimensional cutting for complex frame fronts, compound curves, or undercuts, especially in titanium or carbon fiber frames.

A: We offer micron-level precision, with tolerances up to ±0.005 mm. This ensures that each piece—whether it’s a hinge slot, a bridge mount, or a lens groove—is consistently aligned and structurally sound, even in high-volume production.

A: Absolutely. In fact, we recommend it. Our CNC prototyping service lets you see and test your design before moving to mass production. You’ll be able to evaluate the fit, alignment, material finish, and surface detailing to ensure it meets your expectations.

A: Our CNC line can produce a wide range of precision eyewear parts, including:

Frame fronts (acetate or metal)

Temples and tips

Hinges and embedded metal cores

Nose bridges and pad arms

Metal logos and decorative components

Lens groove shaping and drill-mount holes

Each component is machined to match your exact design specifications.

A: Definitely. CNC machining is the go-to technology for premium eyewear brands due to its superior precision, clean cuts, and ability to replicate intricate designs. It’s ideal for producing luxury titanium frames, multi-layer acetate styles, and frames with engraved logos or texture effects.

A: Quality is at the core of our process. We implement multi-stage QC during CNC production, including:

Pre-run calibration with test cuts

Real-time monitoring of toolpaths

Visual and dimensional inspection after cutting

Fit-testing of assembled components (if required)

ISO-compliant reporting for each production batch

Consistency and symmetry are verified on every frame to ensure they meet international retail standards.

A: Yes! That’s the beauty of CNC. We support one-off prototypes for early-stage development and scale up to mass production runs of 10,000+ units. Since no molding is needed, you can transition from sampling to production seamlessly, with zero tooling delay.

✅ 10+ years of eyewear manufacturing

✅ Fully integrated CNC workshop for frames & components

✅ Exporting to over 30 global markets

✅ ISO-compliant QA/QC standards

✅ Low MOQs for boutique & emerging brands

✅ Multilingual support (English & 中文)

✅ Trusted by wholesalers, designers, and private label clients

✨ We’re not just a factory. We’re your technical partner in modern eyewear production.

Follow Us:

Set your brand apart with custom-designed eyewear! At Eyewearbeyond, we specialize in tailor-made eyeglasses and sunglasses that fit your specifications. Request a quote and start designing now!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Ready to bring your unique eyewear designs to life? Start your journey to custom eyewear today—request your free quote now!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Looking for the perfect custom eyewear to represent your brand?

Our experts can help you find the perfect eyewear solution tailored to your requirements!

You have successfully subscribed to the newsletter

There was an error while trying to send your request. Please try again.