Top 12 Handmade Eyewear Brands to Watch in 2025

In a Mass-Produced World, Handmade Still Stands Apart When it comes to eyewear, there’s something undeniably special about a pair ...

Our handcrafted technical solutions refine every edge, polish every surface, and sculpt each detail—so your brand stands out with unmistakable precision.

There’s something unforgettable about well-made acetate glasses. The texture. The color depth. The curve of a polished temple in your hand. But behind every beautiful frame is a factory that understands not just how to cut acetate—but how to shape it into emotion, identity, and retail success.

At EyewearBeyond, we’ve spent over a decade building eyewear lines for brands across the globe. And when it comes to acetate, we know: your frame isn’t just a product. It’s your signature.

That’s why our acetate production line is engineered to combine machine precision with artisan hand-finishing—delivering custom eyewear that reflects your creative vision with flawless execution.

✅ If you believe in craftsmanship, material quality, and original design—we speak your language.

We only work with top-tier, sustainable materials, including:

🇮🇹 Mazzucchelli acetate: the gold standard for color richness and layered tone

🌱 Bio-acetate: biodegradable, plasticizer-free, and ideal for eco-conscious collections

Our supply chain ensures you get:

Smooth machine cutting with fewer defects

Deep, consistent color that shines through final polish

Frame flexibility and long-term durability

We support end-to-end production of:

Full acetate frame fronts (classic, geometric, oversized, or artistic)

Temples (with core-wire insertions, engravings, or lamination)

Custom lamination & multi-tone styling

Nose bridges & edge shaping

Branding: laser logos, pad printing, and foil stamping

Finishing: mirror-polish, matte, or gradient textures

Every frame undergoes over 30 steps of machine-guided cutting, shaping, and hand polishing—because that’s how you achieve true elegance.

| Stage | Process |

|---|---|

| 1️⃣ | Material selection: Mazzucchelli / Bio-acetate blocks or sheets |

| 2️⃣ | CNC cutting or heat-press shaping into rough frame outlines |

| 3️⃣ | Lamination & color pattern bonding (if needed) |

| 4️⃣ | Tumbling, edge contouring, or beveling |

| 5️⃣ | Slotting hinges & inserting metal cores (temples) |

| 6️⃣ | Hand polishing: glossy, semi-gloss, matte, or brushed finish |

| 7️⃣ | Branding (logo), final QC & packaging |

🔁 Whether you need 300 pieces or 10,000—our workflow adapts to your brand’s size, speed, and styling.

| Feature | Your Advantage |

|---|---|

| Low MOQ | Start from just 100 pcs per style/color |

| Mixed SKUs in 1 batch | Perfect for diverse capsule collections |

| Support for hybrid designs | Acetate + metal core, flexible temple integration |

| Hand polishing | Adds premium finish & product appeal |

| Custom lamination | Showcase multi-tone color play and visual depth |

Our acetate frame line is trusted by:

🌱 Eco-lifestyle brands switching to bio-acetate

🧑🎨 Indie designers seeking small batch production

🕶️ Fashion houses expanding into optical collections

🛍️ Retailers developing private-label eyewear SKUs

Whether you’re creating bold fashion-forward styles, vintage-inspired pieces, or a timeless essentials line, our team helps you bring those ideas into market—with beauty, balance, and brand value in every frame.

Ready to create frames that feel as premium as your brand?

Fast response within 24 hours

Low-MOQ pricing

Prototyping & DFM support

Flexible design and color development

Have you ever held a pair of glasses that just felt different? Not just better made, but more alive—like you could somehow sense the care that went into every curve, polish, and angle?

That’s the magic of handmade acetate eyewear.

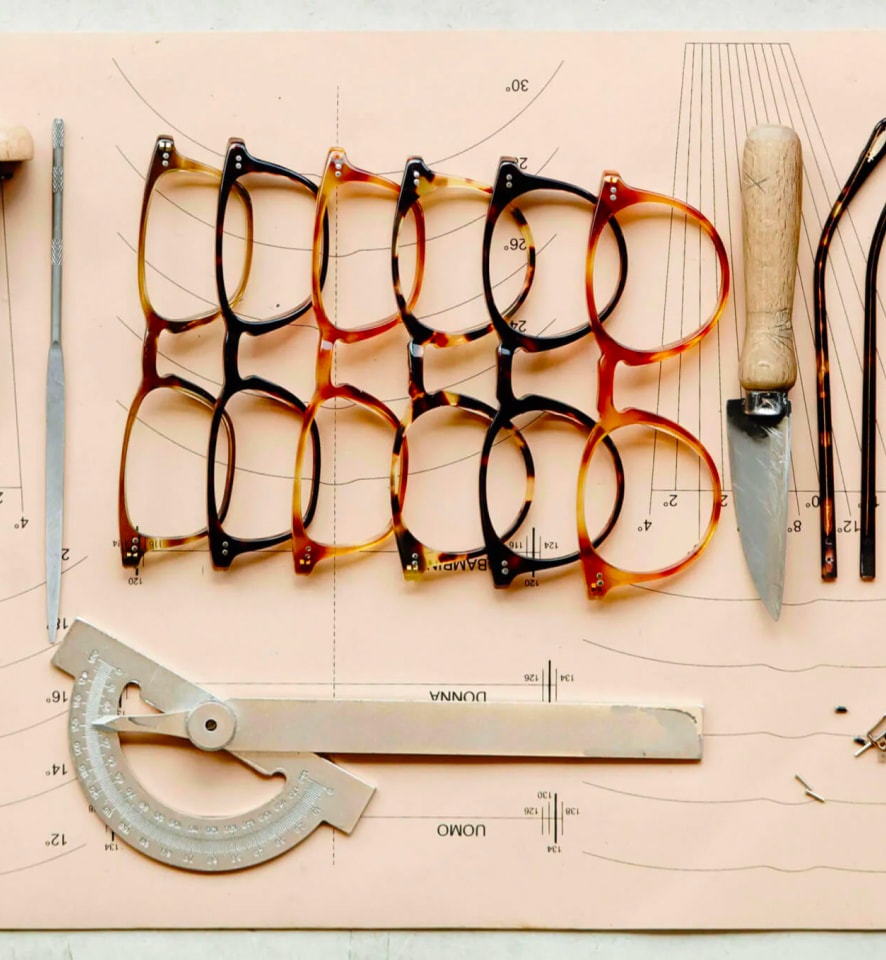

In an age of automation and factory lines, there’s still something incredibly special about frames made by real hands. Each one takes hours—sometimes days—to create. And behind every step is a skilled artisan using tools, not just machines, to shape something truly personal.

Today, we’re peeling back the curtain on that process. Whether you’re an eyewear brand founder, a retailer, or someone who just appreciates great design, here’s everything that goes into making a single pair of handmade acetate frames.

Before we get to the tools and techniques, let’s talk about what we’re working with.

Acetate (technically “cellulose acetate”) is a plant-based plastic made from wood pulp or cotton. Compared to typical petroleum plastics, acetate is more eco-friendly, more flexible, and way better looking.

Why do artisans love working with it? Because acetate holds color beautifully. Think rich marbles, deep gradients, transparent hues—it’s basically a canvas for color. And it can be cut, bent, polished, and shaped without losing that quality. In short: perfect for eyewear.

Read More:How to Make Acetate Eyewear?

Here’s a step-by-step walk through the key techniques that define handmade acetate eyewear.

Lamination & Block Building

Lamination & Block Building

Handmade acetate doesn’t start as a frame—it starts as a block. Or rather, sheets of acetate layered and laminated together.

Craftsmen choose the right color layers and literally fuse them by hand, sometimes aligning specific patterns to create things like tortoise shells, stripes, or gradients. They’ll stack the sheets with care, heat them under pressure, and then let them rest. This curing step is vital—it’s what makes the material stable enough to last for years without warping.

This step is where visual magic begins.

Once the block is ready, it’s time to cut the rough shape of the front.

Some makers use CNC machines for precision, especially for symmetrical cuts—but in many workshops, shapes are traced and cut by hand, especially for custom silhouettes.

Whether using a saw, blade, or a grinding wheel, the maker follows the outline with care, creating a base that still needs lots of refining… but already looks like a pair of glasses.

Hand-Drilling and Slotting

Hand-Drilling and Slotting

Now it’s time to add the functional parts. Holes for:

Lenses

Nose bridge

Hinge placement

Temple connections

Each of these is measured, marked, and drilled by hand using small, sharp tools and guided jigs. This is where alignment matters most—get a hinge even a millimeter off, and you’ve got a frame that pinches, sits crooked, or wears unevenly.

Human judgment wins here.

Inserting the Core Wire in Temples

Inserting the Core Wire in TemplesThose sleek temples on your acetate glasses? Most have a metal core hidden inside for strength and flexibility.

To insert it, artisans heat the acetate temple with warm air until it’s pliable. Then they gently slide the metal core inside, making sure it’s straight, centered, and bubble-free.

It sounds simple. It’s not. Get it wrong, and the whole temple might twist or lose its spring. This is one of those jobs that just takes years of experience to master.

Edge Shaping and Refining

Edge Shaping and RefiningThe frames are now recognizable—but they’re still a little raw.

Artisans hand-file the edges to round off the sharp cuts. They smooth the bridge (so it rests comfortably on your nose), refine the inner temples (so they don’t rub), and shape the ends of the temples to curve naturally behind your ears.

This is where comfort gets built in—not just fit, but that feeling when something hugs your face just right.

Multi-Step Polishing

Multi-Step PolishingThis is the signature move. The one thing you absolutely cannot fake with a machine.

Handmade acetate eyewear is known for its shine—that deep, mirror polish that feels like glass. Here’s how it’s done:

Pre-polishing by hand, smoothing the edges

Tumbling the pieces in big wooden barrels with wax and chips for hours

Buffing with cotton wheels and polishing compound

Final hand-polish for clarity and touch

Some frames even get a brushed matte or satin finish, done with specialized hand tools. Others get engraved textures for depth. Whatever the look, the smooth feel you get on your skin? That’s 100% thanks to human touch.

Hinge & Temple Assembly

Hinge & Temple AssemblyAttaching the temples is a job for steady hands and patient eyes.

Artisans drill tiny holes, align the hinges, and screw or rivet them in by hand. They check the opening resistance, make sure the temples open smoothly, and adjust the angles for a balanced fit.

This is also where things like spring hinges or custom flex features get added. Machines help, but it’s the person at the bench who makes it work just right.

Branding & Personalization

Branding & PersonalizationWant your logo on the frame? That happens here.

Using foil stamping, silk screen, or laser engraving, the brand name or logo is applied by hand—usually under a heated press or guided by a laser. Some makers even inlay metal logos beneath the acetate, sealed forever inside.

What matters most here? Placement, alignment, and sharpness. No smudges allowed.

Final Inspection & Cleaning

Final Inspection & CleaningBefore anything ships, every frame gets:

Checked for fit, balance, and polish

Cleaned with a microfiber cloth

Packaged (by hand) into cases with care cards, accessories, and protection layers

Only after this final step does the frame head out into the world.

Because when something’s made by hand, it’s never just about function—it’s about feeling.

A frame that fits better.

A polish that glows deeper.

A design that feels more… human.

In every pair of handmade acetate frames, there’s a story, a skill, and a soul.

If you’re a brand, this is the kind of product your customers will feel connected to. If you’re a maker—thank you for keeping the craft alive.

Summary: The Heart of Handmade Acetate Eyewear

Summary: The Heart of Handmade Acetate Eyewear| Step | Why It Matters |

|---|---|

| Lamination | Custom color depth and pattern creation |

| Rough cutting | Brings design to life, shape by shape |

| Drilling & slotting | Aligns hinges, bridges, and lenses with care |

| Core wire insertion | Adds flexibility and structure by hand |

| Edge refining | Ensures comfort where it matters most |

| Polishing | Creates that unmistakable high-end shine |

| Assembly | Perfects function, alignment, and movement |

| Branding | Makes it truly yours—forever |

| Final QC | Sends out only the best, frame by frame |

At EyewearBeyond, we believe the future of eyewear doesn’t lie in choosing between machines or hands—it’s in combining both.

Our acetate eyewear production line is equipped with advanced automation, ensuring high-volume precision, clean cuts, and consistent shapes. This gives you reliable quality, especially when scaling up collections.

But what truly sets our frames apart is what happens after the machines stop.

From core wire insertion to edge refinement, multi-stage hand polishing, and final assembly, every frame passes through skilled hands—hands that feel the subtle weight of acetate, adjust the tension of each hinge, and polish corners no machine can reach.

This is how we ensure every frame isn’t just well-made—but crafted. Smooth to the touch. Balanced in the hand. And full of character in the details.

In short: Machines bring consistency. Our artisans bring soul. And you don’t have to choose between the two.

Handmade acetate eyewear isn’t fast fashion. It’s not volume-driven or machine-made at scale. It’s slower, deeper, and better.

And in a world full of disposable things, that kind of beauty really matters.

Whether you’re sourcing for a boutique line, designing your own optical label, or just geeking out on craft—we hope this gave you a whole new appreciation for what it means when someone says:

This blog series explores everything you need to know about handmade acetate eyewear—from how raw acetate is layered, shaped, and polished by hand, to the craftsmanship that transforms each frame into a wearable work of art.

We’ll take you behind the scenes of the artisan process: the tools used, the techniques passed down through generations, and the hands-on decisions that make every frame unique. You’ll discover how real makers breathe life into sheets of Mazzucchelli acetate and turn them into stylish, functional, and character-rich glasses.

Whether you’re a designer starting your first collection or a brand founder refining your product line, these posts will give you insider knowledge, practical insights, and real-world production wisdom to help you understand why handmade still matters in a world of fast fashion and automation.

👉 Because in acetate eyewear, it’s not just about the shape or color—it’s about the soul you can feel in every polished edge and custom curve.

In a Mass-Produced World, Handmade Still Stands Apart When it comes to eyewear, there’s something undeniably special about a pair ...

Introduction: Beautiful Materials Alone Aren’t Enough You’ve probably heard the phrase tossed around: “We use Mazzucchelli acetate.” In the world ...

Let’s Be Honest: It’s the Finish That Makes You Fall in Love If you’ve ever picked up a pair of ...

Introduction: Craftsmanship in Every Curve In a world where speed and automation dominate production, handmade acetate eyewear stands as a ...

Acetate frames are well-loved in the eyewear industry for their lightweight, durable, and flexible nature. They’re not just practical but ...

Acetate, also known as cellulose acetate, is a type of plastic derived from natural sources like wood pulp and cotton ...

We are here to help you 7 days a week and respond within 24 hours. Plus, you can find most answers to your questions right on this page.

A: Our MOQ starts at just 100 pieces per color or 300pcs per style, making it ideal for independent designers, boutique brands, or capsule collections. We understand the importance of flexibility, so we also support mixed SKUs in a single batch, meaning you can produce multiple colors or shapes in one order without meeting a high minimum for each.

A: Yes, we offer custom color development based on your Pantone code or physical acetate swatches. If you’re looking for multi-layered or multi-tone effects, our team can hand-layer different acetate sheets to create bespoke lamination blocks. This is a completely manual process, giving you freedom to achieve your brand’s visual identity through color and transparency.

A: Absolutely. We work with certified bio-acetate suppliers such as Mazzucchelli’s M49 and other biodegradable materials that are plasticizer-free and plant-based. These materials are a growing demand among sustainable eyewear brands, and our craftsmen are trained to cut, polish, and assemble them just like traditional cellulose acetate—without compromising performance or finish.

A: Yes, we offer multiple logo branding options tailored to your design aesthetic:

Laser engraving (discreet and durable)

Foil stamping in gold, silver, or custom colors

Silk screen printing (great for full-color logos)

Pad printing for fine detail or gradient effects

All logo work is done by hand with a precision jig setup to ensure alignment, depth, and clarity.

A: We provide a wide range of surface finishes to elevate your frames:

High-gloss mirror polish (multi-stage hand polishing)

Matte (buffed by hand for a velvety texture)

Sandblasted (for a modern, frosted look)

Brushed finish (adds tactile depth and texture)

Custom textures (achieved with rotary tools or polishing compounds)

Each finish is applied and inspected by hand, ensuring a premium tactile feel and consistency across the collection.

A: Yes. Many acetate temples require a metal core wire for added flexibility and support, especially if you want to use adjustable temples. We insert these manually after heating the acetate with hot air. Our artisans ensure each core is centered, bubble-free, and tension-balanced, making the frame both durable and comfortable to wear.

A: Our polishing process is one of the most crucial handmade steps. It includes:

Initial edge smoothing by hand

Tumbling in wooden barrels with polishing chips

Rotary buffing with wax compounds

Final hand-polishing on cotton wheels for a deep mirror shine

While tumbling is semi-automated, all other polishing and quality inspection steps are done by hand, giving each frame a luxurious finish and skin-smooth surface.

A: Yes, we can design and produce custom acetate bridges with a lower curve and wider pad area to suit Asian-fit or low-nose-bridge wearers. This fit is increasingly popular for comfort and ergonomics, and we use manual shaping and jig testing to ensure precision alignment and pressure distribution.

A: For custom designs, our typical development timeline is:

3–5 days for CAD and material confirmation

7–10 days for prototype sample cutting

15–20 days for final adjustments and pre-production sample

30–45 days for full production depending on volume

Because many steps are handmade, our focus is on accuracy and craftsmanship, not just speed. We’ll communicate every milestone so your launch timeline stays on track.

A: Yes. Unlike mass production, our hand-assembled eyewear line allows you to adjust:

Hinge positioning (for better fit or style)

Temple length (common range: 135mm to 150mm)

Frame angle (pantoscopic tilt) and temple curve

All adjustments are made using manual fixtures and trained hand alignment, ensuring your frames look great and feel even better on the customer’s face.

A: Definitely. If you send us a physical sample, 3D file, or even a hand-drawn sketch, we can reverse-engineer the shape. Our design team will convert it to CAD and prepare a CNC-compatible file. For truly unique shapes, we still cut and shape by hand, especially if the design has asymmetry or intricate curves.

A: In addition to the frames, we can supply or co-develop:

Custom logo cases (pouch, box, or hard case)

Microfiber cloths with your branding

Individual barcode stickers, SKUs, and care cards

Retail-ready packaging or bulk-packed for global distribution

All packing is done by hand with QC checks to ensure every frame arrives clean, aligned, and professionally presented.

📍 Located in China with full-scale acetate manufacturing capacity

✂️ In-house polishing, cutting, lamination, and branding

🌍 Export-ready with compliance for Europe, USA, and Asia

🧰 Low MOQs and flexible styles—ideal for DTC brands or optical chains

💬 Multilingual B2B team (English/中文) ready to collaborate

Let us turn your acetate vision into reality—without compromise.

Follow Us:

Set your brand apart with custom-designed eyewear! At Eyewearbeyond, we specialize in tailor-made eyeglasses and sunglasses that fit your specifications. Request a quote and start designing now!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Ready to bring your unique eyewear designs to life? Start your journey to custom eyewear today—request your free quote now!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Looking for the perfect custom eyewear to represent your brand?

Our experts can help you find the perfect eyewear solution tailored to your requirements!

You have successfully subscribed to the newsletter

There was an error while trying to send your request. Please try again.