Are You Looking for Custom Eyewear Manufacturer?

Eyewear Manufacturers

Eyewearbeyond stands out among eyewear manufacturers by offering bespoke OEM solutions for a wide range of products, including eyeglass frames and sunglasses. Specializing in high-end custom designs, we help brands create unique eyewear that captures attention in the competitive market.

We are a Group of Eyewear Manufacturers

From developed from scratch designs to customized blanks made in China

We are a eyewear manufacturers group based in China. Specialized in Custom high-quality eyewear with an eco-friendly and sustainable philosophy.

Manufacturing inspiring eyewear is our passion.

Our highly qualified team includes :

We work with well known international brands, but we also support new brands in their path to success.

We’re not just eyewear supplier, we’re your business partners.

25 Years of Experience

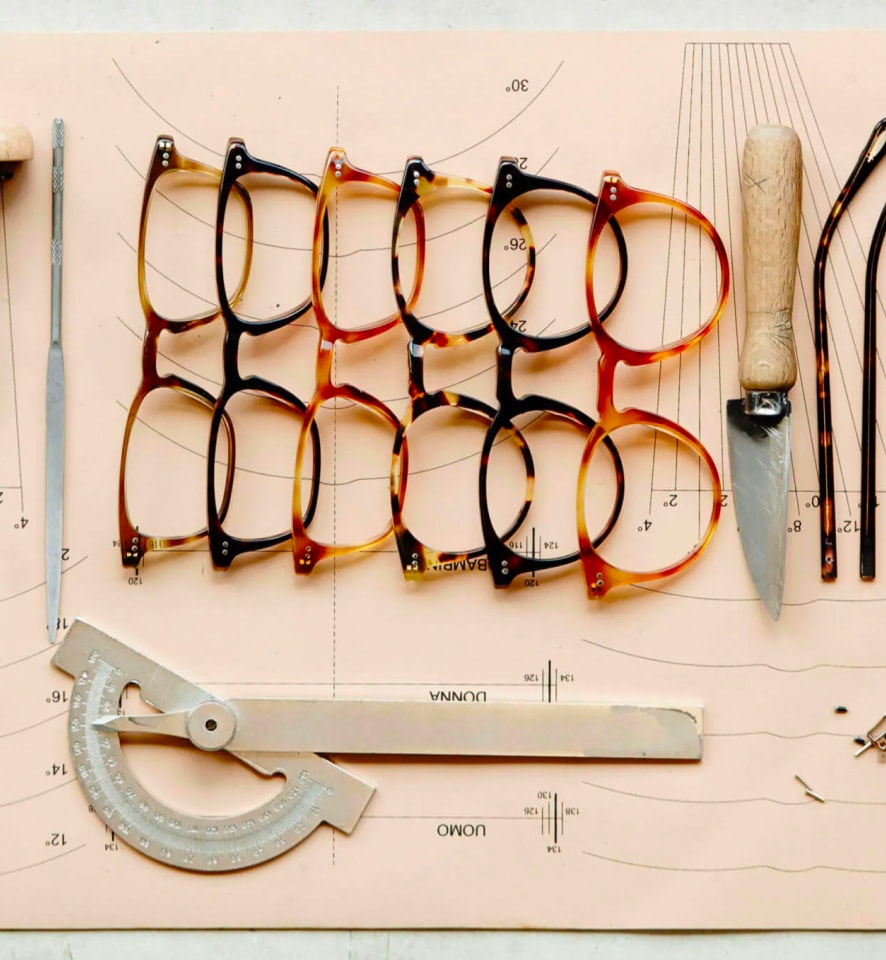

CRAFT

250 Steps, 71 hours, and 13 Craftsmen.

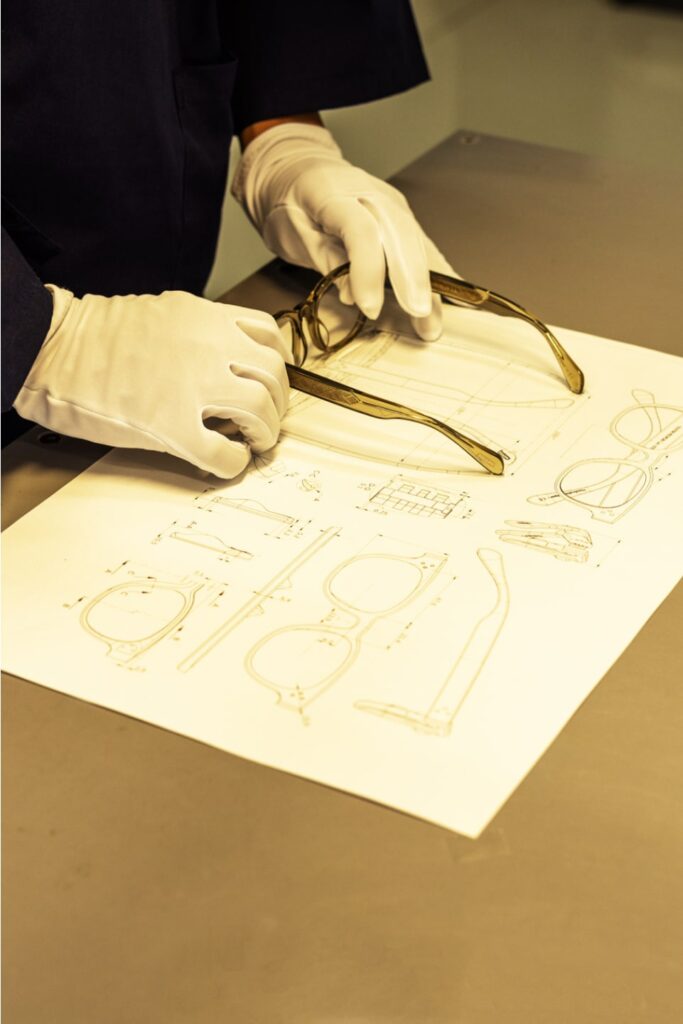

Each of our designs is crafted by hand in the renowned eyewear workshops as many as 200+ steps to bring to life. This is eyewear created through 25 years of experimentation and creative exploration: each frame reflecting a unique journey from concept to construction. We never stop seeking new innovative techniques to express our ideas.

Design

Prototyping

Innovative

Bulk Production

Create Eyewear From Scratch/ 300pcs per Modle MOQ

BEST FOR ESTABLISHED BRANDS & TECH PACK DESIGNERS

Custom Eyewear Development or Bespoke Frame Manufacturing MOQ Starts at 300 Units — Your Ultimate Choice for Creating Fully Personalized Eyewear from Scratch.

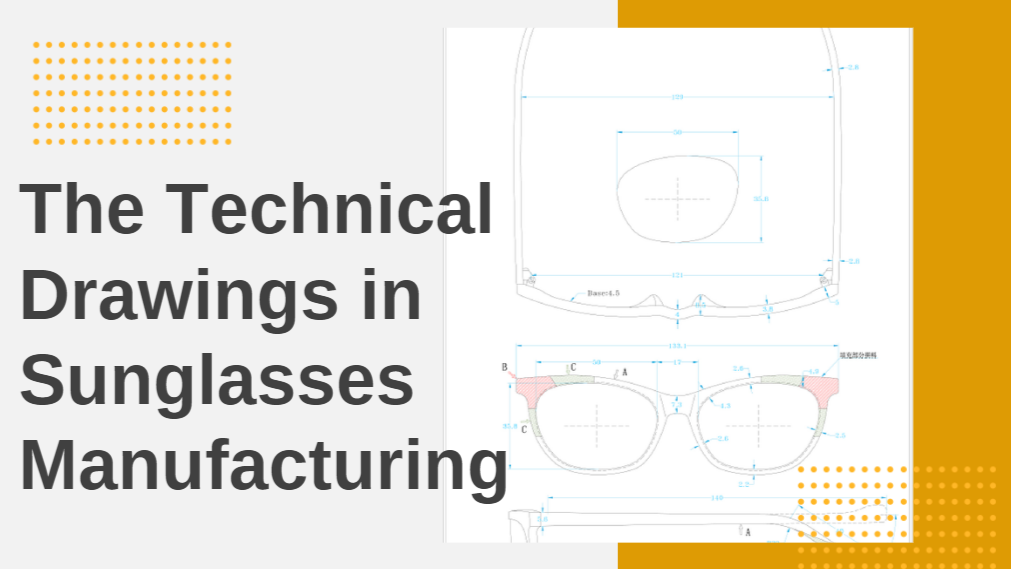

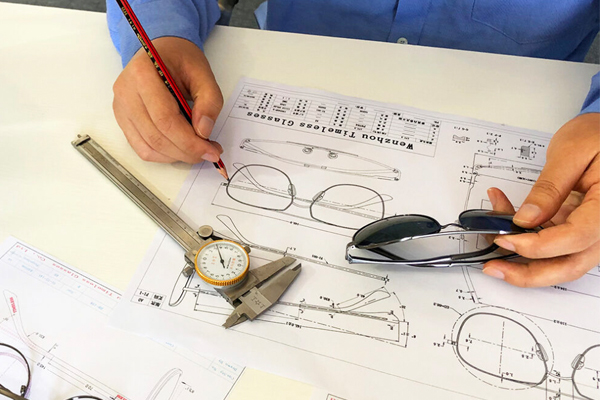

To start, you’ll need to provide a technical drawing or 3D design file, with detailed size specifications, material choices, color options, logo placement, and finishing details.

We can also work with physical samples as a reference if available.

It may require a bigger upfront investment in product development, but the result will be a truly unique and exclusive eyewear collection.

Go ahead and explore the types of eyewear we specialize in:

√ Optical Frames √ Sunglasses √ Sports Glasses

√ Reading Glasses √ Blue Light Glasses √ Kids' Glasses and more

Main Services

One-stop eyewear manufacturer We fit your needs.

Build Your Own Custom Eyewear Brand from Scratch

How We Work

Step 1: Share Your Vision

To bring your custom eyewear to life, we’ll need a technical pack — including frame dimensions, material selections, color references, logo placement, and finishing details.

Step 2: No Tech Pack? No Problem.

If you’re new to the eyewear world and don’t have technical drawings yet, we can still help.

Simply send us a physical sample of a frame you like. We’ll use it to recreate the key measurements and design features, then develop your own custom version.

Step 3: No Sample Available? We Have Solutions.

If you don’t have an eyewear sample ready, you can send us material samples (like acetate sheets, titanium pieces, or temple tips). Based on these, we’ll help source or suggest similar materials to match your vision.

Whether you have a clear design in mind or just an idea, we’ll work closely with you to turn it into a fully customized eyewear collection.

We Take Care of Your Eyewear Development — From Concept to Production

How It Works

Provide us with your technical drawings, including frame dimensions, material specifications, and color references.

We will help you:

Source the perfect materials (acetate, titanium, stainless steel, etc.)

Create prototype patterns and sample frames

Develop detailed salesman samples for review

Move seamlessly into full-scale production of your eyewear collection

Send your tech packs directly to us by email — and let’s start building your brand.

Full Control Over Your Eyewear Production

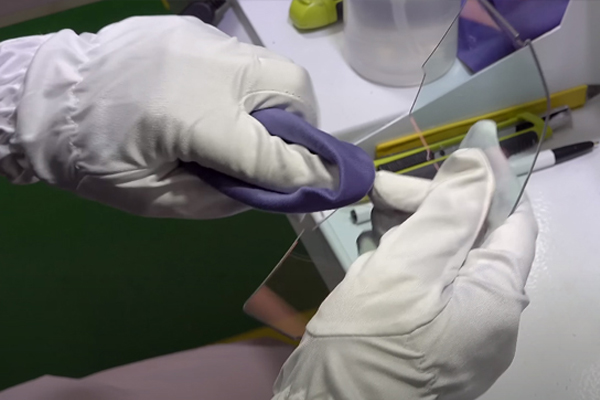

Our team is made up of experienced quality control specialists, working independently to oversee every step of the eyewear manufacturing process.

This hands-on approach ensures that every frame meets the highest quality standards — from start to finish.

Here’s how we guarantee excellence:

1 – QC on Raw Materials:

Inspection of acetate sheets, titanium, stainless steel, hinges, lenses, and all incoming materials upon arrival at our factory.

2 – QC on Frame Prototypes:

Careful quality checks on design patterns, initial samples, and technical accuracy before mass production.

3 – QC During Mass Production:

Monitoring frame cutting, CNC machining, polishing, and assembly to ensure precision at scale.

4 – QC on Final Finishing:

Detailed inspection of special finishing processes, logo applications, lens fitting, final polishing, individual packaging, and labeling.

With full in-house control, we deliver premium-quality eyewear you can trust — every time.

We Create Salesman Samples for Your Future Eyewear Production

If you have an upcoming trade show or important sales event and need high-quality eyewear prototypes to present to your buyers, we have the perfect solution.

Our team can manufacture your custom samples upfront — giving you the flexibility to showcase and sell your eyewear models now, and move into full production with us later.

Secure your orders first. Launch your production when you’re ready.

Private Label Eyewear

Choose styles from our eyewear collection and customize them with your own unique design.

Build your eyewear brand quickly with market-ready frame styles

No mold or pattern development costs

Select from styles that are already proven to fit current trends

Minimum order — 10 pieces per color/style

Launch your private label collection faster and with full customization options.

Eco-Friendly Eyewear: Organic Acetate and Bamboo Wood

We proudly offer eyewear crafted from organic acetate and sustainably sourced bamboo wood.

Our organic acetate uses plant-based plasticizers, and our bamboo is harvested responsibly to protect natural ecosystems.

Throughout the production process, we focus on energy-saving techniques and resource-efficient methods, minimizing waste and reducing our environmental impact.

At the same time, we are continuously investing in technological advancements to enhance production efficiency and product quality.

By choosing these eco-friendly materials, you not only create beautiful eyewear but also support a greener, more sustainable future.

Partner with us to build an eco-conscious eyewear brand backed by innovation and responsibility.

PROUD OF OUR PRODUCTS AND RELENTLESS IN PERFECTION

With a broad range of skills and EXPERTISE IN EYEWEAR MANUFACTURING, and a highly efficient production facility, we are capable of producing optical frames, sunglasses, sports eyewear, and kids’ eyewear collections.

Our long journey in the luxury eyewear manufacturing industry began with the creation of high-quality, precision-crafted eyewear.

Our capabilities go far beyond basic frame assembly — we manage every critical stage of production:

Surface Treatments

Laser Engraving, Foil Application, UV Printing, 3D Printing, Logo Etching

Detail Finishing

Hand-Polished Surfaces, 3D Logo Applications, Reflective Accents, Stone Embellishments

Prototyping & Samples

Full-Service Technical Drawings, Prototype Frames, Pre-Production (PP) Samples

Branding & Accessories

Custom Metal Logos, Embedded Acetate Logos, Personalized Packaging, Woven Pouches, Sustainable Eyewear Cases

At every step, we combine artisanal craftsmanship with advanced technology, delivering eyewear collections that elevate brands and inspire customers worldwide.

METAL

Masters of Metal

Using the finest metals in the world — titanium, stainless steel, sterling silver, and 18k solid gold — our master craftsmen transform raw materials into intricately detailed works of art, employing techniques few others would attempt: prioritizing quality over mass production.

ACETATE

Sculptors of Acetate

Our acetate forms are sculpted exclusively from an organic plastic derived from cotton and cured for over three months prior to construction. This lengthy process produces uniquely rich colors with unrivaled strength and durability. Each piece is then hand-finished by master polishers who have apprenticed for 10 years to perfect their technique, producing a remarkably soft feel, sculpted for a lifetime of hard use.

CONSTRUCTION

Architects Of Eyewear

Every hinge, temple, and component used in our eyewear is thoughtfully considered and uniquely designed for each collection. From our iconic side shields to our innovative pince-nez bridges, our designs are an unmistakable homage to our heritage today, redefined for tomorrow.

LENSES

A Clear Vision

Our lenses are lighter and more impact-resistant than glass and filter out 100% of harmful UVA and UVB light. Each lens is treated with seven layers of anti-reflective coating. This reduces eye strain by eliminating unwanted reflections. For even greater clarity, our polarized lenses filter out distracting glare and enhance contrast.

PROCESS

Finishing Touches

Once each piece of eyewear has been hand-assembled and meticulously inspected for imperfections, it is adjusted and aligned to meet our highest quality standards. This rigorous process reflects 50 years of mastery in creating products designed for your expression.

Featured Custom Eyewear Series We offer

Custom Eyewear Collection – where style meets scalability. This exclusive series is crafted for custom buyers, sunglass brands, wholesalers, and independent brands looking to differentiate their product offerings in the competitive market. Embrace the ultimate in customization and quality with our bespoke eyewear solutions.

OEM/Custom Sunglass Manufacturer

Partner with us as your Custom Sunglass Manufacturer and bring your unique vision to life. We specialize in creating high-quality sunglasses tailored to your brand’s

OEM/Custom Eyewear Packing

Enhance your brand’s presentation with Custom Eyewear Packaging, designed to complement your unique eyewear collection. From eco-friendly materials to luxurious finishes, we offer fully customizable

OEM/Custom Ski Goggles

Elevate your brand with Custom Ski Goggles, engineered for peak performance on the slopes. Our goggles feature anti-fog, windproof, and anti-glare technology, ensuring clear vision

OEM/Custom Sports Eyewear

Elevate your brand with our Custom Sports Eyewear, designed for all types of athletic activities. Whether it’s cycling, running, skiing, or water sports, our eyewear

OEM/Custom Eco Wooden Eyewear

Elevate your collection with our Custom Eco Wooden Eyewear, made from sustainable materials like pure wood, laminated wood, and wood combined with acetate, titanium, or

OEM/Custom Buffalo Horn Eyewear

Elevate your eyewear collection with our Custom Buffalo Horn Eyewear, made from natural, eco-friendly buffalo horn. Each handcrafted frame offers unique beauty, lightweight comfort, and

OEM/Custom Highend Titanium Eyewear

Elevate your eyewear collection with our Custom High-End Titanium Eyewear, crafted from premium pure titanium, BETA titanium, and titanium alloys. We also offer designs that

OEM/Custom Highend Acetate Eyewear

Elevate your eyewear collection with our Custom High-End Acetate Eyewear, crafted from premium 6.0, 8.0, and 10.0 thickness acetates for ultimate durability and style. We

OEM/Custom Highend Metal Eyewear

Elevate your eyewear collection with our Custom High-End Metal Eyewear, expertly crafted from a selection of premium metals including titanium, stainless steel, and precious alloys

Ask for an Instant Quote

A good supplier can not only make you worry-free, but also enable your business to develop sustainably and allow your brand to continuously accumulate reputation for service and quality.

Be Careful When Choosing A New Eyewear Supplier, The DISAPPOINTMENT of low quality lasts much longer than the Joy of LOW PRICE!

Practical Technology of Custom Eyewear

Table of Contents

A Comprehensive Guide to Understanding Eyewear Parts

Eyewear Main Parts

- Frame Front

- Lenses

- Bridge

- Nose Pads

- Rims

- Temples (Arms)

- Hinges

- End Pieces

- Temple Tips

- Screws

Sub-Type Parts

- Acetate | Charniers | Cross head screws | Curl sides | Dowel screws | Drop end | Hidden hinges | Hinge graves | Hockey end | Joint | Keyhole bridge | Lens groove | Loop ends | Pad arms | Pad bridge | Paddle temple | Regular bridge | Rim | Rimless | Side shields | Spring hinges | Supra chord | Tenons | Windsor rim | Wire cores

A Detailed Guide :How to Custom/OEM Eyewear?

For Prenium Custom Suggestion

1. Introduction

Briefly highlight the uniqueness of custom eyewear.

Emphasize how personalized eyewear enhances comfort, style, and functionality.

2. Identifying Your Vision

Clarify your purpose: prescription glasses, sunglasses, or fashion eyewear.

Align your eyewear with your lifestyle: active, professional, or casual.

Address any specific needs: material preferences, durability, and more.

3. Choosing the Ideal Frame Design

Explore various frame shapes: round, square, aviator, etc.

Tips for selecting a frame that complements different face shapes.

Considerations for frame materials: metal, acetate, titanium, and more.

4. Selecting the Right Lenses

Overview of lens types: single vision, bifocal, progressive.

Choosing the right lens material: plastic, polycarbonate, high-index, glass.

Lens enhancements: anti-reflective coating, UV protection, blue light filter.

5. Customization Possibilities

Explore custom frame colors and patterns.

Personalization options like engraving or branding (logos, names).

Tailored adjustments: nose pads and temple tips for a perfect fit.

6. Ensuring a Perfect Fit

How to measure your pupillary distance (PD) accurately.

Understanding frame dimensions: lens width, bridge width, temple length.

Tips for ensuring a comfortable and secure fit.

7. Partnering with a Trusted Manufacturer

How to effectively communicate your custom design ideas.

The importance of choosing a reputable and experienced manufacturer.

Understanding production timelines and minimum order quantities.

8. Quality Assurance and Certification

Steps to ensure your custom eyewear meets quality standards.

Importance of certifications like CE, ANSI, ISO.

Final inspection tips before accepting your custom order.

9. Caring for Your Custom Eyewear

Best practices for cleaning and storing your personalized eyewear.

Tips on maintaining the longevity of your custom frames and lenses.

Understanding warranty and repair options for your custom eyewear.

10. Conclusion

Summarize the key steps to creating custom eyewear.

Encourage readers to take the next step in designing their unique eyewear.

Call-to-action: Reach out to your trusted eyewear manufacturer to start your custom order today.

Manufacturer-Side Custom Brief

- What Eyewear Can Custom?

- What Eyewear Parts can Custom?

- What are the Custom Process for each Eyewear Series ?

- How To Start Your Eyewear Custom?

Analyze for Eyewear Protetype Cost

- How Much Does It Cost to Have an eyewear protetype Made?

- How to Get an eyewear protetype Quote?

- What is a Reasonable Cost for an eyewear protetype?

- Why are eyewear protetype so Expensive to Make?

The Ultimate Guide : How to Find the Right Custom Eyewear Supplier in China

Understanding the Chinese Eyewear Manufacturing Industry

- Overview of China’s role in global eyewear production

- Key regions in China known for eyewear manufacturing

Advantages of Working with a Chinese Eyewear Supplier

- Competitive pricing due to economies of scale

- Access to a wide range of materials and advanced manufacturing technologies

- Expertise in both large-scale production and custom designs

- Flexibility in minimum order quantities (MOQs) and customization options

- Strong global shipping networks and experience with international markets

Identifying Your Custom Eyewear Needs

- Defining your brand’s specific requirements (materials, design, MOQ, etc.)

- Determining budget and pricing expectations

Researching Potential Suppliers

- How to find suppliers through online platforms (e.g., Alibaba, Made-in-China)

- Attending trade shows and industry exhibitions in China

- Utilizing referrals and industry networks

Evaluating Supplier Credentials

- Checking certifications and compliance with international standards

- Assessing the supplier’s production capacity and technology

- Reviewing past client feedback and case studies

Quality Control and Sample Testing

- Importance of requesting samples before committing to large orders

- Tips for inspecting sample quality and craftsmanship

- Implementing a quality control process with your supplier

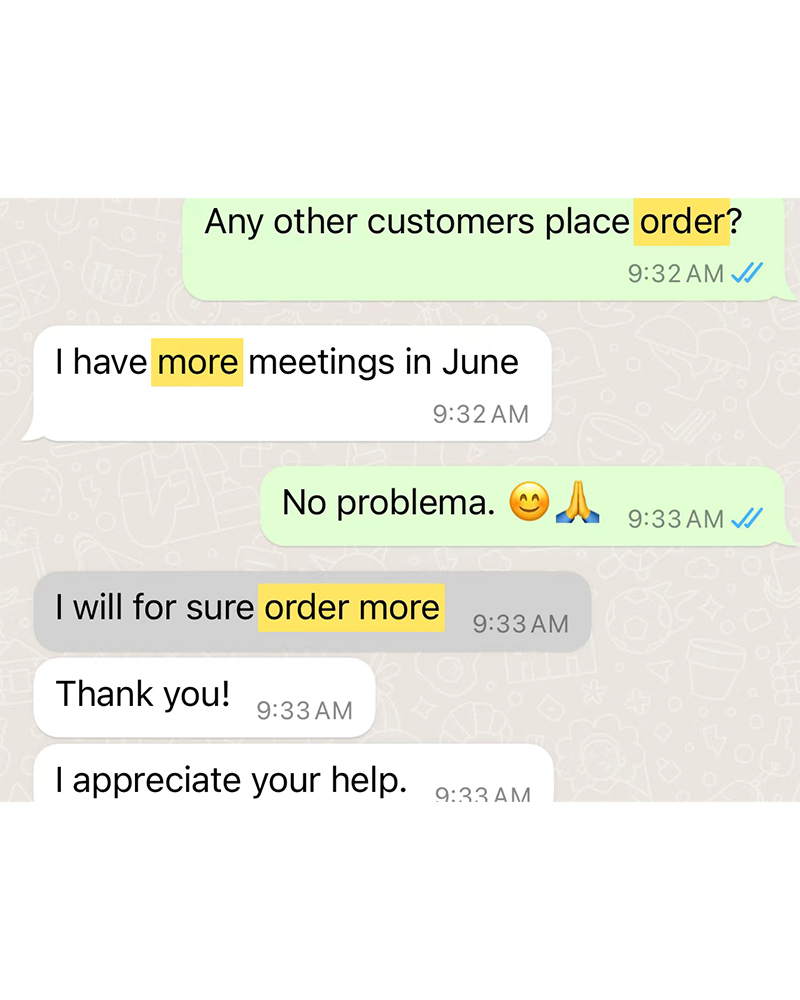

Communication and Negotiation

- Establishing clear communication channels with your supplier

- Tips for negotiating terms, pricing, and lead times

- Importance of cultural understanding and building a strong business relationship

Visiting the Manufacturer

- Benefits of visiting the factory in person

- Key aspects to observe during a factory tour

- Preparing questions and discussion points for the visit

Managing Logistics and Shipping

- Understanding the logistics involved in importing eyewear from China

- Choosing reliable shipping and logistics partners

- Managing customs, duties, and other import-related considerations

Long-term Supplier Relationships

- Strategies for maintaining a good working relationship with your supplier

- How to handle issues or disputes effectively

- Planning for future growth and collaboration

FAQs about Custom Eyewear

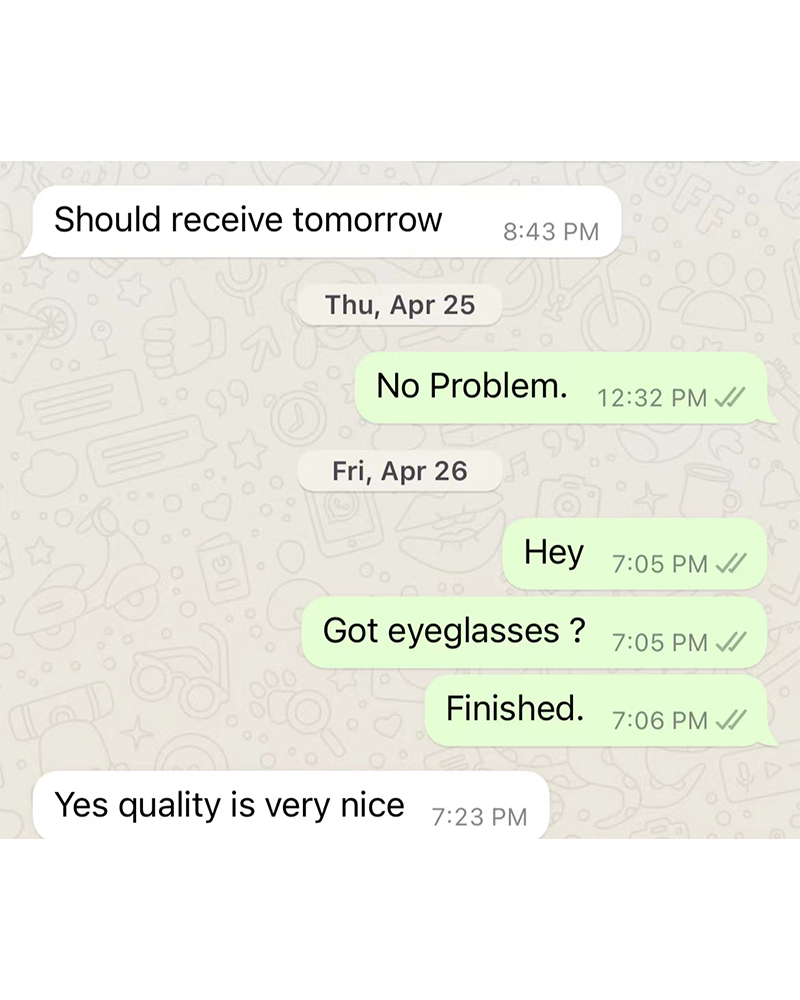

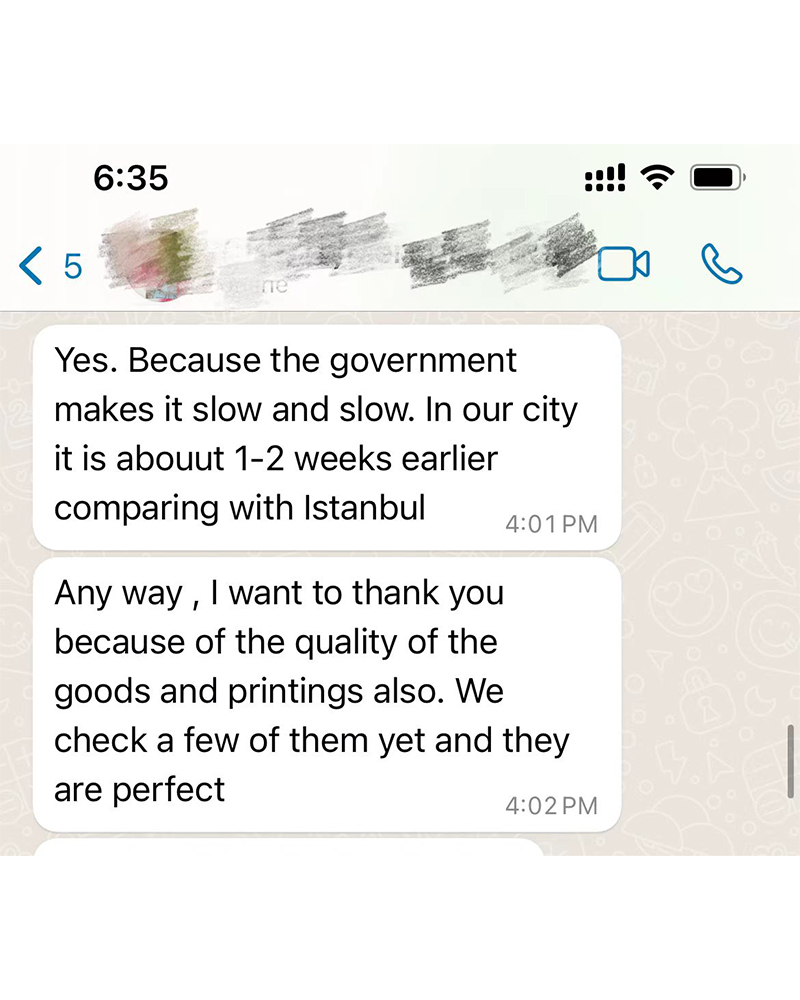

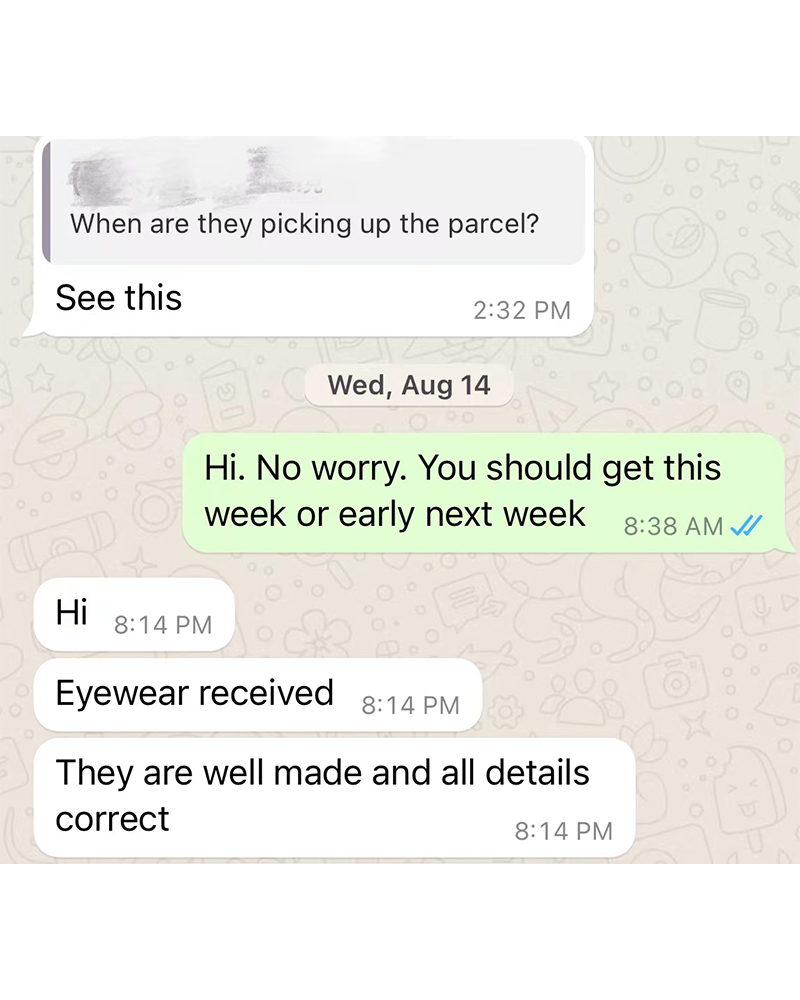

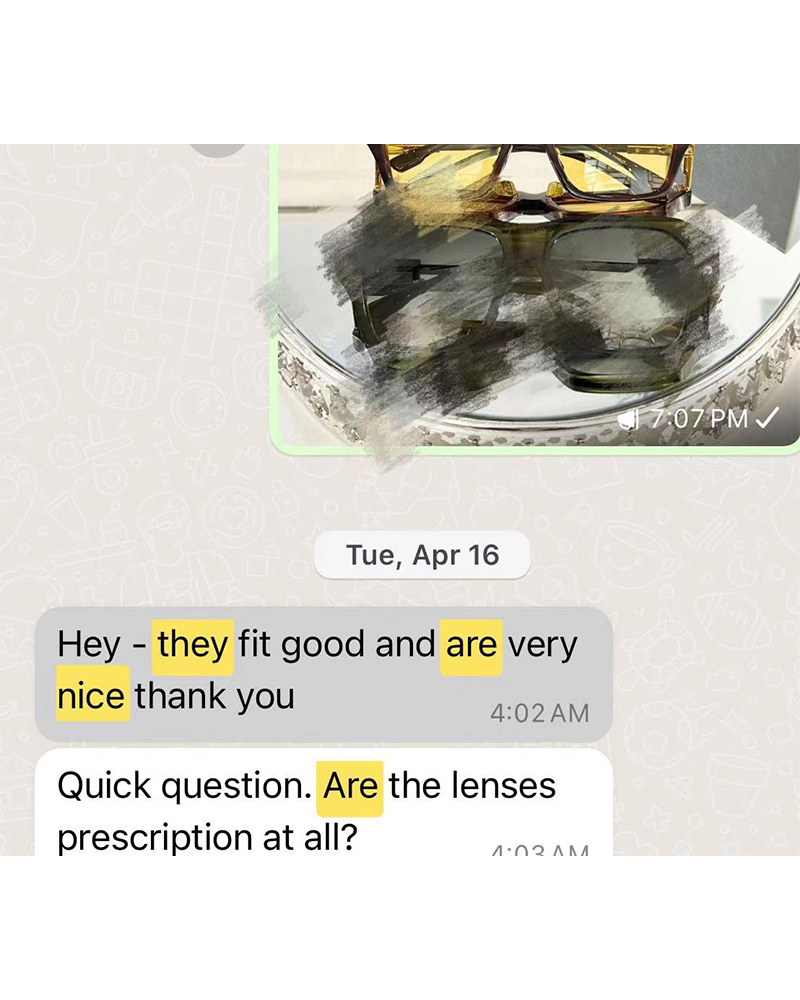

See How Customers Reviews Eyewearbeyond

Custom Eyewear Design Techs Download

Related Blogs for Custom Eyewear

Get an Instant Quote

REQUEST A QUOTE

Ready to Work Together? Build a project with us!

A Comprehensive Guide to Understanding Eyewear Parts

Why Should You Understand the Basic Parts of Eyeglasses Before Customizing Your Own?

When it comes to creating a custom eyewear brand, the allure of designing unique, stylish frames that represent your brand’s identity is undeniable. However, as exciting as this process is, diving into customization without a solid understanding of the basic parts of eyeglasses can lead to costly mistakes, unsatisfied customers, and a tarnished brand reputation. Before you embark on the journey of creating custom eyewear, it’s essential to familiarize yourself with the fundamental components of eyeglasses to ensure that your designs are not only aesthetically pleasing but also functional and comfortable.

Understanding Eyeglass Parts: The Foundation of Quality Customization

The key to successful eyewear customization lies in understanding the basic parts of eyeglasses. Knowing the purpose, functionality, and materials used for each component will help you make informed decisions that enhance the comfort, durability, and style of your products. This knowledge is vital whether you’re working with a manufacturer or designing the frames yourself. From the lenses and frame materials to the hinges and nose pads, each element plays a critical role in the overall performance of the glasses. A deep understanding of these components will empower you to create eyewear that not only meets aesthetic expectations but also adheres to quality standards that your customers will appreciate.

Why is This Knowledge Crucial for Your Brand’s Success?

Understanding eyeglass components isn’t just a technical requirement; it’s a strategic advantage. By mastering the details of eyeglass parts, you can communicate more effectively with manufacturers, avoid common design pitfalls, and make choices that will set your brand apart in a competitive market. With this foundation, you’ll be able to innovate while ensuring your products remain practical and reliable.

In this article, we’ve put together a list of the main parts of glasses frames and what they’re really called. Here’s a brief overview.

Glasses frames comprise of three main parts, containing multiple sub-parts within their construction. Primarily, there is the frame-front and two protrusions known as temples. These main components come in many different forms and materials which have their own specific functions, styles and names.

Frame front | Endpieces | Bridge | Lenses | Temples | Temple tips | Hinges | Screws | Nose pads | Rivets | Other parts of glasses

What are the names of the parts of glasses?

- Frame front

This is the main part of your glasses frame. It’s what secures your lenses in place.

Your frame front largely dictates the style and aesthetic of your glasses, a considerable factor in how you want to put yourself across.

As you’ll have seen, frame fronts vary in terms of their material, colour shape and size. They can be made from various types of material, predominantly cellulose acetate, metal or high-performance composites such as carbon fibre.

Before plastic came on the scene, (1907,) natural materials such as bone, wood, ivory, horn and real tortoise shell were used to make the frame front and temples of a glasses frame. Since then, materials such as cellulose acetate has generally made these older materials obsolete.

Frame front types

Full rim frame fronts cover the entire edge of a lens. Your lenses are held in place using an angled recess in the frame front called a lens groove.

Half rim frame fronts are the same as full rim but their lower half is missing. This means the bottom edges of your lenses are exposed and are secured in place using a thin nylon chord called “Supra.”

Rimless frame fronts are joined together via a metal bridge. Via screws, the bridge joins and secures the lenses together to make the frame front. At the edges of the lenses, the temples are also attached via screws through the outer-sides of each lens.

Frame front sub-parts

Bridge | Endpieces | Hinge graves | Hinges | Lenses | Lens groove | Pad bridge | Rivets | Supra

A tortoise acetate frame front with a double rivet cluster on the endpiece.

- Endpieces

At the outermost edges of your frame front, are the glasses endpieces.

This is where the temples locate onto the rear side of the frame front via the hinges. Endpieces vary in size and shape, depending on the style of temples on your glasses.

Endpiece types

Full rim/half rim endpieces usually have recess on their rear-side to accommodate the hinge. This recess is called a hinge grave where the hinge locates into the frame material surface. Depending on the type of hinge, you’ll often see rivets that pass right through the frame front in order to fasten the hinge.

Rimless endpieces are actually part of temple instead of the front. Beyond the hinge is another section of metal called a “lug”, which is usually a bent at an angle of about 96°. The lug is then screwed through the lens to create a firm joint.

Endpiece sub-parts

Rivets | Deco rivet | Hidden hinge | Hinge graves | Hinges | Lenses

Four types of metal glasses bridges. Far right example is a metal keyhole bridge.

- Bridge

What is the bridge on glasses?

Sounds simple, but your glasses bridge is exactly that. It bridges your nose.

For facial comfort, the bridge of your glasses has two main functions. These come from bridge bump and the bridge aperture.

From above, you’ll notice that the bridge protrudes slightly from your glasses frame. This is called the “bump” which creates room for the crest (top) of your nose as the glasses rest on your face.

The bridge aperture, also called the bridge apical radius, can be seen from the front of the frame. This space makes room for the majority of your nose. Without this space, your nose couldn’t locate into your glasses frame.

Bridge sub-types

Regular bridges are a continuous, flowing shape which make a U-shaped slot in the frame front. This style of bridge is relatively modern and is very simple in appearance.

Keyhole bridges are a traditional style of bridge which resembles that of a keyhole. This bridge-style is generally more classic, associated with full rim eyewear design from the mid-century.

Metal bridges are used for either rimless frame fronts or for acetate “split frames.” For acetate split frames, a conjoining piece of metal is riveted or screwed into the separate acetate rims to join them together.

For rimless frames, it’s very much the same but the bridge is attached with screws through the lenses instead.

Bridge sub-parts

Keyhole bridge | Metal bridge | Nose pads | Pad bridge | Regular bridge

Examples of a concave and a convex lens. These lenses are actually made from glass but most modern lenses are made from CR39 plastic.

- Lenses

Arguably the most important part of your glasses, the lenses are there to correct your vision.

There are many types of spectacle lenses, which were originally made from glass. However nowadays, most if not all spectacle lenses are made from types of high index plastic.

Depending on the type of frame front, your lenses are secured into your gasses using different types of friction fit. The optical term for fitting your lenses is a process called glazing.

Full rim frames have an angled female recess on the inside of the rim called a lens groove. This recess is about 1.5mm deep at an angle 120°. Cut onto the edge of the lens is a ‘male’ bevel which locates into a ‘female’ lens groove by heating and gently stretching the frame front.

Half rim frames also have a lens groove but with the addition of a Supra chord. This nylon string locates into a female recess around the edge of lens which holds it into place in the frame.

Rimless frame lenses are secure via screws into the bridge and endpieces.

Lens sub-types

Bifocal | Prescription reader | Ready reader | Single vision | Varifocal | CR39 | Crown glass | Plano | Polycarbonate | Trivex | Supra

A tortoise acetate example of a hockey-end temple. Dual rivet | 5 tenon hinge | Wire core

- Temples

What part of glasses is the temple?

Oh boy these parts of glasses have some strange names.

Some call them legs, other call them arms.

Seems logical…but the proper name for them is temples, simply because they locate on each side of your head.

There are numerous styles of temple, but their main function is to keep your glasses secure when you’re wearing them.

Interestingly, temples are actually relatively modern as old-fashioned glasses didn’t originally have them. Instead, these old styles of glasses without temples just rested on your nose or were held to the face via a handle.

Yep, we’re talking templeless glasses here folks like lorgnettes and monocles.

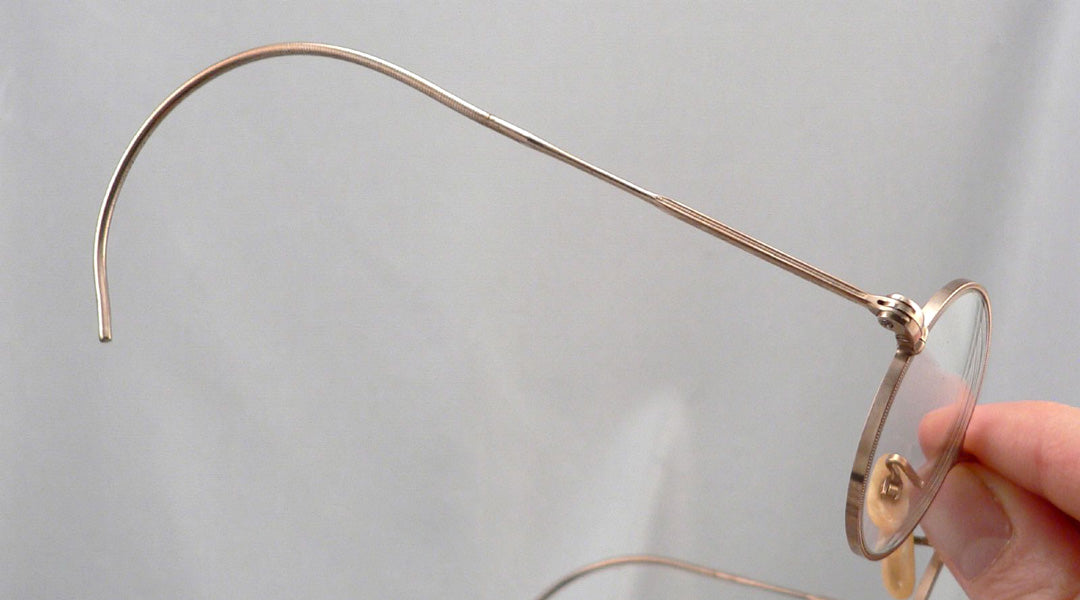

Today, glasses temples tend to be made from acetate or metal and use what’s called a drop end or a hockey end. This is the hooked part of the temple that’s grips behind your ear to keep them from sliding off your face, usually at an angle of about 45°.

Glasses temples are made at various lengths to suit different head sizes and vary from 120mm to 150mm in length.

Wondering what length of temple you need?

This information is usually printed or etched onto the inside of the temple itself or occasionally the inside of the frame front. Alongside the bridge with and lens diameter, the temple length is part of the three main dimensions of a glasses frame.

Do you have a transparent acetate glasses frame?

If so, you might notice a strip of metal inside the temple. This component is called a wire core which is used to reinforce the acetate to help keep its shape.

Without this, your temples would eventually become warped and would require repeated heat adjustments to keep them in the correct shape. The wire core helps maintain adjustments carried out by your optician.

Temple sub-types

Blade temple | Curl sides | Drop end | Hockey end | Paddle temple | Unipiece temple

Temple sub-components

Frame dimensions | Hinges | Hinge graves | Rivets | Wire cores

An array of different temple tips made from acetate. These tips slot over the ends of metal temples to provide a comfortable fit behind your ears.

- Temple tips

What are temple tips?

At the end of your temples are the temple tips.

These are the furthest away from your frame and are made in various iterations.

Acetate glasses temple tips are usually part of the temple itself. However, they can also be added to the end of metal temples, similar to a sock. Seen in the images above, there are different colours, patterns and shapes of acetate temple tip which can be added to a metal temple.

Metal temple tips are usually covered or coated with plastic or rubber to make them more comfortable. However, our uni-piece temple design is cylindrical in form and tapered which reduces the need for additional parts and makes them incredibly easy to wear.

Loop end temple tips are hollow loops which can be found at the end of a straight metal wire temple. These loops are to distribute pressure on the sides of your head and can also be used to attach a frame chain.

An assortment of metal spectacle hinges which can either be riveted, screwed, melted or soldered into a glasses frame.

- Hinges

Your hinges are the metal joints which allow you to open and close the temples on your glasses frame.

Hinges can also be called “joints” as they conveniently join your frame front with each of your temples.

And yep, you guessed it, there’s many variations of glasses hinges which are secured via many different methods. Check out the list below.

Hinge sub-types

Tenon hinges are an extremely common hinge-type used for solid full rim glasses made from acetate, horn or composite fibre.

The term tenons, also called charniers, describes the threaded metal loops which interlock with each other to join the frame and the temples together. Tenon hinges are a very stable type of hinge and come is different tenon counts such as 3, 5, 7 and 9.

Characteristically, tenon hinges do not have any “give” as they are not sprung. When the temple is fully open and meets the frame, a tenon hinge will no let it open any further; a similar function to a house-door.

If your glasses have a tenon hinges, they will likely be fastened in one of two ways, either via pin rivets or heat-insertion. Pin riveting is the most traditional method of attaching a tenon hinge to a glasses frame as they provide a solid fix between the hinge and the frame front.

Spring hinges are also very common and are used in full rim and rimless glasses frames.

They are characterised by their “give.” In other words, when you fully open the temple, it can extend beyond it’s maximum distance range. This is because of the in-built spring within the hinge, hence the name.

Spring hinges are common amongst low cost glasses frames such as ready readers. They can cater for a wider range of head shapes and offer a one-size-fits-all mechanism.

However, it’s worth noting that spring hinges are generally less stable than tenon hinges due to the internal spring mechanism which is more likely to break.

Hidden hinges are identical to tenon hinges, except they have no additional fasteners such as rivets.

Instead, hidden hinges are inserted into the frame via heat or ultrasonic friction which rapidly melts the acetate surrounding the hinge.

This melt makes a sturdy bond between the hinge and the frame without the need for rivets. As you can imagine, hidden hinges are a sleeker design with less components, however they are very rarely repairable.

Because hidden hinges have no rivets, brands and manufacturers may opt to use deco rivets or dummy rivets which mimic the use of real ones. This is done to yield a more traditional construction aesthetic.

Mechanical hinges are bespoke hinges which use cleverly engineered components to reduce the parts and “bulk” of traditional tenon hinges.

Instead of using screws and tenons, mechanical hinges may use entirely wooden or intricate folded metal parts which avoid the need for pin riveted hinges.

Hinges like these are less common as they tend to be used in high-end, technical glasses frames.

Hinge sub-components & types

Charniers | Tenons | Hidden hinges | Hinges | Hinge graves | Rivets | Dowel screws | Cross head screws

Thread seeking screws have a detachable “nose” which makes them easier to locate into the threaded tenons of a hinge. Screw head: Dowel

- Screws

The screws are what join the two halves of a hinge together.

Using one screw per hinge, the screws locate through the interlocked tenons of your glasses hinges.

Once located, the screws can be tightened to adjust the opening and closing mechanism of your temples. This can be a personal preference as to how tight or loose you want this to be.

If you’ve lost a screw from your glasses frame, you’ll be able to get a replacement from your local optician. Or, if you’re a Banton Frameworks customer, you can request a pair of replacement thread seeking screws by contacting us here.

Screw sub-types

Dowel screws are the most common type of glasses screw. They are characterised by the straight slot in the top of the screw head.

Cross head screws are slightly less common and use a cross shaped (Phillips) slot in the top of the screw head.

Thread seeking screws are a fantastic design which makes it easier for you to locate the screw into the top tenon of the hinge. They do this via an extended metal “nose” which tapers to a fine point. This nose can then be snapped off once the screw is fully tightened into the hinge as it is no longer required.

See also: Dowel screws | Cross head screws | Thread seeking screws | Tenons | Charniers | Hinges

Three examples of hypoallergenic spectacle nose-pads. Silicone and titanium.

- Nose pads

What are the nose pieces on glasses called?

The nose pads of your glasses are the little humps or circular pads that rest on your nose.

Depending on what style of frame front you have, there are various types of nose pads for glasses frames. These can either part of the frame front material or as a separate metal piece called a pad arm.

Nose pad sub-types

Full rim nose pads are almost always part of the frame front. When the frame front is being cut from the acetate or horn sheet, the nose pads are sculpted as part of the frame as a single piece.

Nose pads like these are very robust and can be adjusted by filing the acetate or horn away to reduce their height. To make them smooth again, the nose pads require hand polishing so they aren’t rough on your nose.

Push in nose pads are a secondary item which use a separate glasses part called a pad arm. The pad arms are either inserted into an acetate/horn frame front or attached to a metal front via soldering. Once the pad arm is attached to the frame, a nose pad can be attached to end where it rests on your nose.

Push in nose pads vary in shape, size and material depending on your preference. The bigger the nose pad, the more visible it is. However large nose pads distribute more pressure and are less likely to “dig” into your skin.

Ideally, nose pads should always be hypoallergenic which minimises their chances of reacting with your skin. This is why metal pads are usually titanium and plastic ones are made of rubber or acetate.

See also: Pad arms | Pad bridge

Example 1: Pointed, pan-head rivets | Example 2: Staple rivets | Example 3: Tapered rivets

- Rivets

If your glasses have tenon hinges, they’ll most likely be fastened via two or three little metal rivets.

The rivets are located in a tightly-packed cluster on the frame front endpiece and the outside of the temple near the hinge.

As mentioned previously, the rivets are located through small diameter holes in the frame front and the temple which are used to permanently fasten the hinges.

Using a process called riveting, sometimes called staking, the ends of the rivets are squashed, deformed and widened to squeeze the hinge onto the frame front or the temples.

Depending on the type of hinge, the amount of rivets can vary between a two-cluster and a three-cluster formation which are used equally for the frame and the temple.

- Two-cluster formations means a glasses frame will have 8 rivets in total (four for each side.)

- Three-cluster formations means a glasses frame will have 12 rivets in total.

Rivet sub-types

Pan head rivets look similar to a wood-nail. They have a uniform 1mm shank and a wider, circular flat top which can be seen on the frame front endpiece.

Double rivets have two 1mm shanks which are joined together at the top via a conjoining strip of metal called a cross bar. Rivets like these can be branded or styled as per a company’s branding.

Tapered rivets have a conical shank and don’t have a top. Instead they taper from a wide head down to a narrow tip at the bottom.

Style rivets have a decorative head which can be shaped to resemble a company emblem or certain geometry. These are less common but offer minor degree of differentiation from regular pan head or tapered rivets.

Deco rivets are used on full rim frames to mimic the appearance of actual rivets. Instead of passing through the frame, deco rivets are entirely superficial, added to the surface of a frame which uses hidden hinges.

Related rivet parts

Hinges | Hinge graves | Rivet hole | Rivet head | Rivet shank

Other parts of glasses

If you’ve made it this far, you’ll know by now that there’s A LOT of styles and types when it comes to the various parts of glasses.

In this more detailed section, you can explore the sub-types of each component to get an idea of their shape, style, material and function.

Why not use the link-box below for easy navigation?

Acetate | Charniers | Cross head screws | Curl sides | Dowel screws | Drop end | Hidden hinges | Hinge graves | Hockey end | Joint | Keyhole bridge | Lens groove | Loop ends | Pad arms | Pad bridge | Paddle temple | Regular bridge | Rim | Rimless | Side shields | Spring hinges | Supra chord | Tenons | Windsor rim | Wire cores

Acetate

Acetate glasses frames are made from a type of bio-plastic called cellulose acetate.

This incredible material is a natural compound which derives from the fibres in cotton ‘bolls’ or mashed up wood pulp.

Due to their high levels of cellulose, wood or cotton are both excellent sources which are cultivated, refined and mixed with acetic acid to make the sheet material, cellulose acetate.

Acetate comes in a vast variety of colours, patterns and transparencies which make it one of the best polymers for spectacle making.

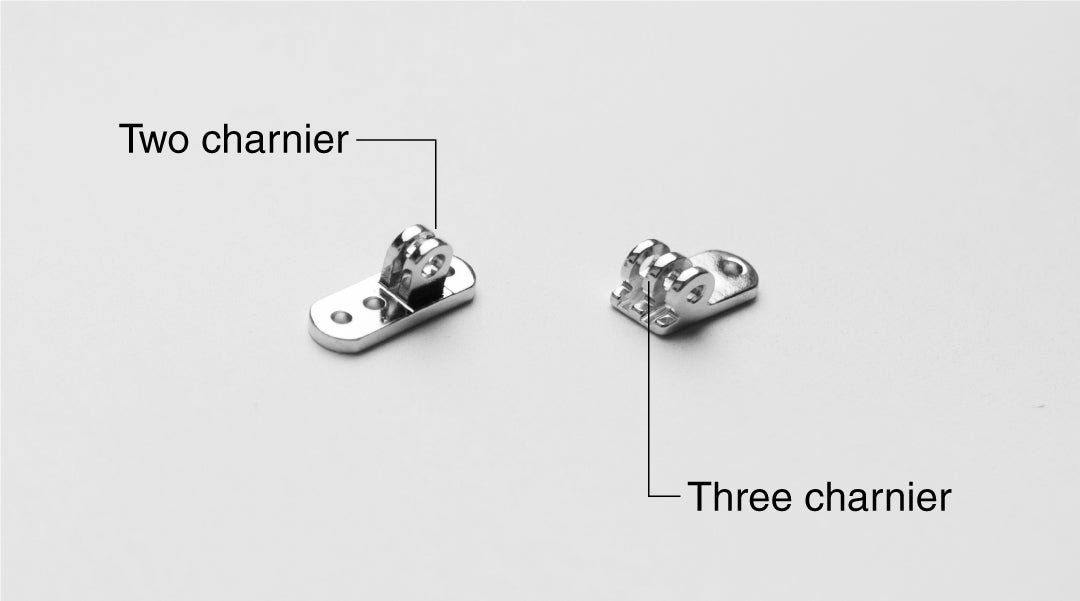

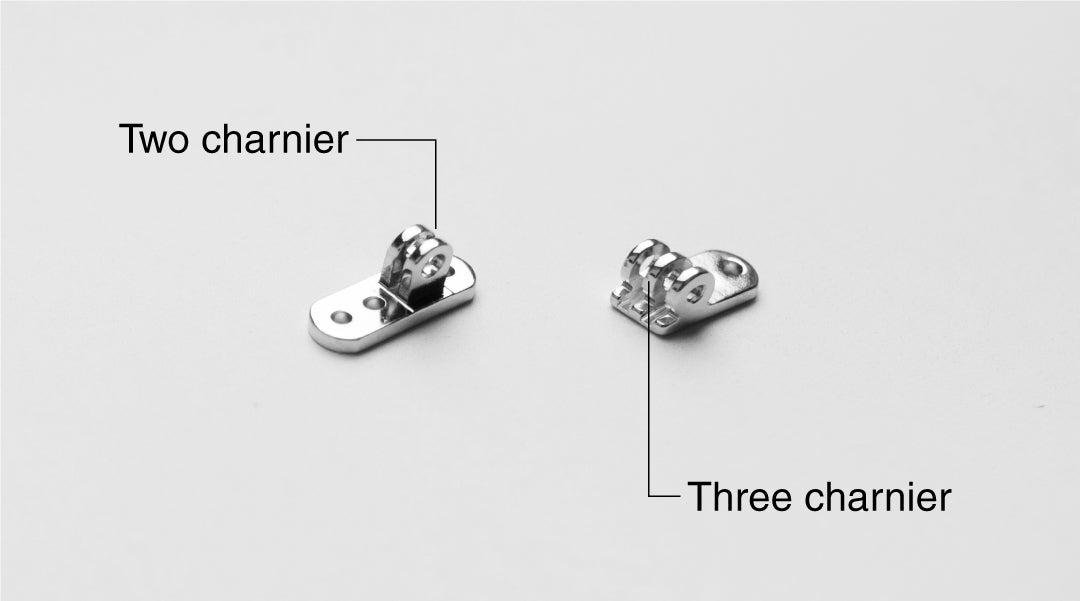

An example of a five charnier glasses hinge with a two rivet cluster. The frame half-joint has two charniers and the temple half joint has three charniers.

Charniers

Sounds fancy. French even.

(It is actually French.)

But the charniers of a glasses hinge are the little protruding loops that interlock with one another to create a fully assembled hinge.

Seen in the image above, each of the charniers have a hole in their centre’s. This is where a threaded screw locates to secure all the loops together. Each half of the fully assembled hinge is called a half joint.

See also: Tenons | Screws | Hinges

Cross head screws

Glasses screws are generally two types.

There are dowel screws and there are cross head screws.

In the images above, you can see the characteristic cross head at the top of each of the screw-heads.

Depending on the hinge-type, glasses screws will vary in length to pass right through the interlocking tenons to hold them all securely together.

See also: Dowel screws | Tenons | Charniers | Hinges

Curl sides

Functional, traditional and oh so snug.

Curl sides do exactly that. They curl behind your ear to give a very secure and snug fit, perfect if you like to keep your frame tight to your face.

Curl sides are more common amongst wire rim frames as the temples tend to be equally fine in thickness. The ends themselves are actually sprung as they’re made of very fine coiled metal, much like a spring.

This temple-style became prominent during the late 1800’s and were popular for more strenuous activities such as horse riding. Wearers benefited from their secure fit around the ear, keeping their glasses frame in perfect place.

Because of their intense grip on your head, curl sides are generally best cut to size for your individual head-dimensions.

See also: Temples | Paddle temple | Drop end | Hockey end

Dowel screws

Also called a “flat head” or “slot screw,” these are an extremely common screw-type.

These little screws are what holds your entire glasses frame together and are arguably one of the most important parts of glasses frames.

In each of your hinges, the dowel screw locates and into each of the threaded tenons. Using a flat-headed screwdriver, the screw is wound tight to pull each half joint together to create a firm and durable connection.

Over time, dowel screws may work loose, so it’s always handy to have an optical screwdriver to keep them tight, but not too tight.

Over-tightening your glasses screws may damage the fine threads, either in the hinge tenons or on the screw shank. Take care to avoid this.

You heard it here.

See also: Cross head screws | Tenons | Charniers | Hinges

Drop end

In modern eyewear, glasses temples generally use what’s called a “drop end”.

The “drop” happens in the last portion of the temple where it hooks downward to create a secure fit behind your ears. Drop ends can also be called “hockey end” or “swan neck” for obvious reasons.

Temples without a drop are either called a paddle or a blade temple, depending on their shape.

See also: Hockey end | Paddle temple | Blade temple | Curl sides

Two hidden hinges. These are both frame front half joints with a three tenon count.

Hidden hinges

Mentioned earlier, hidden hinges avoid the requirement for traditional fastening methods such as rivets.

Instead, the two little “lugs” under the base-plate act like tree roots in the acetate frame front. Because they’re barbed, they create an undercut which makes them more stable.

Hidden hinges are only used for acetate gasses frames due to the way their inserted.

To insert the hinges, each individual hinge is rapidly heated and pushed into the acetate endpiece. The acetate melts around the lugs which creates a firm and minimal fix.

Due to the lack of rivets, hidden hinges require less space within the frame front. This makes them preferable if a designer/brand want to minimise the prominence of the endpiece.

Here’s a quick video of a hidden hinge being inserted into an acetate frame front.

See also: Hinges | Hinge graves | Spring hinges | Endpieces | Rivets

A triple-rivet hinge grave which has been freshly machined into this full rim acetate frame front.

Hinge graves

See the D-shaped recess in this acetate frame front?

Yep, that’s the hinge grave.

Sounds a little morbid but that’s where the base-plate of a hinge goes to rest before it’s permanently fastened with rivets. The purpose of the hinge grave is to make the base-plate “flush” to the surface of the acetate which makes for a sleeker, more pleasing fixture.

Furthermore, the inner walls of the hinge grave also provide lateral support for riveting which prevent the hinge from moving around as the rivets are peened.

See also: Hinges | Joint | Rivets | Rivet hole

An unpolished, tortoise acetate hockey end temple with a two rivet cluster and a visible wire core.

Hockey end

Just like a hockey stick, temples with a hockey end are curled to hook behind your ear.

In the history of eyewear, this feature is relatively modern as it only came to prominence in the 20th century. Before the introduction of drop end/ hockey end, temples were usually straight in form (paddle) or were a metal curl side.

See also: Drop end | Curl sides | Paddle temple

Joint

Another name for your glasses hinges, a fully assembled joint comprises of two half joints held together with a dowel screw.

A frame front will always contain two half joints, one on the rear-side of each endpiece. Generally, these half joints will contain fewer tenons than the half joints on the temple half joints.

For example, a 5 tenon joint means the frame-half-joint will have two tenons and on the temple there will be three tenons.

Joints/hinges use an odd number of tenons and come in different tenon-counts. These generally vary between a 3, 5, 7 and very occasionally a 9 tenon-count.

Se also: Dowel screws | Cross head screws | Hinges | Tenons | Charniers | Hinge graves

An example of a keyhole bridge in our unisex glasses model: D-TRT

Keyhole bridge

Clue’s in the title.

This style of bridge resembles that of a traditional key-hole. As you can see in the image above, the keyhole bridge emits a classic,1950’s aesthetic. This bridge-style is ubiquitous with mid-century eyewear design and production.

A simplified version of the keyhole bridge would be the less intricate “regular bridge” or as it’s sometimes called, a “saddle bridge” which resembles a simple “U” shape.

See also: Regular bridge | Bridge | Pad bridge

Close view of an 120° angled lens groove within this round tortoise acetate frame front.

Lens groove

Your lenses have to go somewhere right?

Seen above, the continuous recess within the rim of the frame front is what holds the edge of a lens in place. The angle of the cut is usually at 120° at a depth of about 1.5mm.

Together, this makes the optimum angle and depth to receive the bevelled edge of an optical lens. As the lens groove is female, and the edge of the lens is male, this union creates a reliable, repeatable connection without the requirement of screws or adhesives.

To locate the lens fully into the lens groove, the frame front is gently heated using an optical blow-heater. This makes the frame front more malleable which allows a skilled technician to slightly stretch the frame over the full edge of the lens.

In optics, this process is known as glazing and if done correctly, makes a secure and sometimes audible fit as lens “pops” into place.

As the frame cools, it contracts around the edges of the lenses thus furthering the security of the lens fit.

See also: Lenses

Loop ends

Also called a ring-end.

Located at the end of each temple, loop ends were designed like a bolt-washer to distribute the pressure of the temples on each side of the wearer’s head. They also provided a handy loop-hole for securing a leather strap to wear as a frame-chain.

See also: Curl sides | Drop end | Hockey end | Temples | Paddle temple

Pad arms

These little arms are used to add nose pads to a frame front.

As seen above, two little barbed pegs are forcefully inserted into the rear-surface of a frame front on either side of the nose aperture.

Once located, a nose pad could be attached via a very small threaded screw through the box-section of the pad arm. The box allows the nose pad to pivot slightly to accommodate the shape of your nose.

This swivel-action also reduces the need for repeated minor adjustments which may damage a pad arm from repeated bending.

See also: Nose pads | Pad bridge | Bridge | Keyhole bridge | Regular bridge

Pad bridge

Instead of using pad arms, full rim glasses frame made from acetate or horn commonly use what’s called a pad bridge.

This is where two little humps are sculpted into the frame front which rest on either side of your nose. Pads like these are extremely common in modern eyewear as they are made during the CNC machining stage of production.

Compared to pad arms, pad bridges are less likely to break as they are part of the frame itself. They can also be adjusted by reducing their height or changing their different angle with a rough file.

Once filed, the acetate or horn can then be hand polished to make each pad smooth again so it won’t rub on your nose.

To accommodate for different facial genetics, pad bridges are made to be more prominent for Asian eyewear markets. The pads tend to be much taller to make the frame more comfortable for wearers with a shallow nose.

See also: Bridge | Pad arms | Nose pads

Phillip Johnson wearing his thick rimmed architect glasses with their prominent paddle temples.

Paddle temple

Simple and straight to the point, paddle temples are uniform across their entire length and do not use a drop/hockey end.

This style of temple harks back to antiquated spectacle design where temples were considered as “grippers” instead of something that could hook behind your ear. This is because eyeglasses were worn intermittently instead of all day.

In essence, paddle temples are less refined than drop ends but they yield a very traditional aesthetic and have a certain style appeal.

In sports such as cycling or sailing, paddle temples are actually preferable as they’re less likely to interfere with safety helmet straps.

See also: Temples | Drop end | Hockey end | Curl sides

Example of a regular or “saddle” bridge on a reading glasses frame.

Regular bridge

Also called a saddle bridge, regular bridges are U-shaped and are simple and continuous in their form.

See also: Keyhole bridge | Bridge | Pad bridge

Rim

Full rim and half rim glasses frames each have a rim.

The rim can vary in thickness, but fundamentally it hosts the the lens groove and makes up the body of the frame front.

See also: Frame front | Half rim | Lens groove | Acetate

Rimless

These are the most minimal type of glades frame.

Instead of having a solid rim that surrounds each lens, rimless glasses rely on the lenses to make the majority of the frame front.

In the middle, a metal bridge is screwed onto the innermost edge of each lens. The screws pass right through the lens which make the basic frame front. At the outside edges (the endpieces) the hinges are also screwed through the lenses to complete the frame assembly.

Spectacles like these are less dominant on the face and can be very lightweight. They’re a good choice if don’t want to attract attention to your glasses but they have a habit of making you look older.

This is because they tend to lack colour and vibrancy which can make them appear somewhat impersonal and dull. If you’re looking for a more youthful glasses style, you should check out the article below.

Glasses that make you look younger

See also: Half rim | Full rim | Lenses

Side shields

Whether they’re fitted to sunglasses or spectacles, side shields have a fairly basic function. They close the gap between the edges of the frame front and your face.

For sunglasses, side shields tend to made from entirely opaque materials such as suede leather or rubber. This is to reduce sunlight from “leaking-in” from above, below or from the sides of the lenses.

This addition prevents what’s known as bounce back and also blocks debris from entering your eyes. This is why they’re popular for exposed activities such as mountaineering or riding a motorcycle.

For spectacles, side shields are generally used as a protective measure, especially in factory environments. To aid vision, they’re usually made from transparent, high impact resistant optical plastic such as Trivex or polycarbonate to let as much light-in as possible.

See also: Trivex | Polycarbonate

Spring hinges

Spring hinges are a modern adaptation of a traditional tenon hinge which reduces the need for manual adjustments.

On the temple half joint, the hinge body conceals a spring which allows the temple to extend beyond it’s maximum range of motion. This makes the glasses frame more adaptable for more head sizes as it can “spring” wider than a traditional tenon hinge.

(See image above)

Spring hinges are common amongst reader readers as they can adapt to a wide range of head sizes; a one-size-fits-all solution.

Over time, low-cost spring hinges are known to fail which renders the hinge completely loose. This failure reduces the efficacy of the temples gripping your head which usually results in the frame’s disposal.

See also: Hinges | Joint | Tenons

Supra chord

For half rim glasses, the lens is exposed in the majority of the lower half.

So in order to secure the lenses into the frame front, a female V-shaped groove is cut into the edge of the lens. This is where A Supra chord is wraps around the lens-edge which is then threaded into the frame.

By adding tension the nylon chord, the lens is pulled into the frame front which ties it into place. If you look closely at the image above, you can see the fine nylon chord and V-groove on the lens-edge.

See also: Lens groove

Tenons

On almost any glasses hinge are these little threaded loops called tenons.

They protrude upward from the base-plate of the hinge with equal sized gaps between each tenon. Each half joint of the hinge can interlock with one another via each of the tenons to create a “stack” of tenons which are secured together with a dowel screw.

Depending on the style of glasses frame, hinges can vary in tenon count from 3, 5, 7 and very occasionally a 9. The number is always odd in order to create a more stable tenon-stack.

Tenons may also be called charniers.

See also: Charniers | Hinges | Joint | Half joint | Hinge grave | Dowel screw | Cross head screw

Windsor rim

Frame fronts made from a wire rim may use an acetate beading called a Windsor rim.

This addition is made from acetate and acts like a tubular sheathe which envelopes the outer edge of the wire. The tubular, hollow acetate is very fine and has a split down its length to accommodate the frame.

Due to the vast variety of acetate colours and patterns, Windsor rims introduce colour and vibrancy to a metal wire frame. Furthermore, the acetate sheathe can be replaced if it becomes worn or damaged.

The acetate itself also acts as a protective barrier to the frame as it may be made from precious metals such as gold, silver or titanium.

Two example of wire cores for temples, one with an in-built half joint and one without. The textured finish is to hide any imperfections within the temple if it’s made from transparent acetate.

Wire cores

Wire cores are one of the more discreet parts of glasses.

Sometimes entirely hidden within the acetate, they’re used to reinforce your glasses temples to prevent them from losing their shape.

To get them into the acetate, both the metal core and the acetate temple are heated using an oven. Then, with great accuracy and speed, the core is forcefully “shot” into the hot, pliable acetate.

Once cool, the temple contracts around the wire core to create a permanent composite. The acetate remains soft, hypoallergenic and attractive whilst the core provides durable structure.

Using a machine, the temples are bent to give them a drop end. The wire core maintains this hook and prevents it from becoming deformed over time.

See also: Temples

A Detailed Guide :How to Custom/OEM Eyewear?

For Prenium Custom Suggestion

Introduction

Custom eyewear is more than just a pair of glasses—it’s a reflection of your personality, style, and unique needs. Imagine wearing glasses that are designed specifically for you, not just in terms of aesthetics, but also in how they fit your face, align with your lifestyle, and meet your vision needs. Personalized eyewear takes the comfort, style, and functionality of regular glasses to the next level, offering a tailored experience that off-the-shelf options simply can’t match.

Identifying Your Vision

Before you dive into the world of custom eyewear, it’s crucial to identify what you need from your glasses. Are you looking for prescription glasses that correct your vision, or are you more interested in sunglasses that protect your eyes from UV rays? Maybe you’re after fashion eyewear that adds a stylish touch to your outfits. Knowing your purpose will guide you in making the best choices for your custom glasses.

Next, think about your lifestyle. Are you someone who’s constantly on the move, leading an active life? Or do you spend most of your time in a professional setting, needing glasses that are both sleek and formal? Perhaps you’re looking for something more casual and versatile. Your lifestyle will play a big role in determining the design, materials, and features of your custom eyewear.

Finally, consider any specific needs or preferences you might have. Do you have a preference for certain materials, like lightweight titanium or durable acetate? Are you particularly tough on your glasses and need something that can withstand a bit of rough handling? By clarifying these aspects, you’ll be better equipped to design eyewear that’s perfectly suited to your needs.

Choosing the Ideal Frame Design

Once you’ve identified your vision, it’s time to dive into the fun part—choosing the perfect frame design. The shape of your frames can dramatically impact not just how your glasses look, but also how they complement your face shape.

There are countless frame shapes to explore—round, square, aviator, cat-eye, and more. Each has its own vibe and can enhance different facial features. For example, round frames can soften angular faces, while square frames can add definition to rounder faces. If you’re not sure which shape suits you best, try on a few different styles or consult with a professional for advice.

Beyond shape, consider the material of your frames. Metal frames, such as those made from titanium, offer a sleek and modern look, plus they’re incredibly durable. Acetate frames, on the other hand, come in a variety of colors and patterns, giving you more room for creative expression. For those who want something ultra-lightweight, titanium or TR-90 might be the way to go. The material you choose will not only affect the style but also the weight, flexibility, and durability of your glasses.

Selecting the Right Lenses

Now that you’ve nailed down your frame design, it’s time to focus on the lenses. After all, lenses are the most critical part of any eyewear—they’re what make your glasses functional, whether for vision correction or eye protection.

First, consider the type of lenses you need. Single vision lenses are great for correcting either nearsightedness or farsightedness, while bifocal lenses can correct both, with distinct sections for near and far vision. Progressive lenses are another option, offering a more seamless transition between different prescriptions without the visible line you get with bifocals.

Next, think about the material for your lenses. Plastic lenses are lightweight and affordable, making them a popular choice. Polycarbonate lenses are even lighter and more impact-resistant, which makes them ideal for sports or for children’s eyewear. High-index lenses are thinner and lighter, perfect for stronger prescriptions, and glass lenses, while offering excellent clarity, are heavier and more prone to shattering.

You can also enhance your lenses with various coatings and treatments. Anti-reflective coating reduces glare, which is particularly useful for nighttime driving or working on a computer. UV protection is a must for sunglasses, blocking harmful rays from damaging your eyes. Blue light filters are increasingly popular, especially for those who spend a lot of time in front of screens.

Customization Possibilities

One of the most exciting aspects of custom eyewear is the ability to make it truly your own. This goes beyond just choosing a frame shape and lens type—you can personalize almost every aspect of your glasses.

For starters, consider customizing the color and pattern of your frames. Whether you prefer a classic tortoiseshell, a bold red, or a subtle matte black, the choice is yours. Some brands even offer the option to mix and match colors or to create completely unique patterns that reflect your personal style.

Personalization doesn’t stop at aesthetics. You can also add engravings or branding to your glasses. This could be as simple as having your name or initials etched on the inside of the temple or as bold as incorporating your logo into the design. Such details add a layer of exclusivity to your eyewear, making them truly one-of-a-kind.

Don’t forget about the fit. Tailored adjustments like customized nose pads and temple tips ensure that your glasses sit comfortably on your face, without slipping or pinching. These small tweaks can make a big difference in how your glasses feel, especially if you wear them all day.

Ensuring a Perfect Fit

Speaking of fit, getting this right is crucial for both comfort and functionality. One of the key measurements you’ll need is your pupillary distance (PD), which is the distance between the centers of your pupils. This measurement ensures that your lenses are positioned correctly in the frames for optimal vision. Many optometrists can measure your PD, or you can do it yourself at home with a ruler and a mirror.

In addition to PD, you’ll need to understand the dimensions of your frames. This includes the lens width, bridge width, and temple length. These measurements are typically printed on the inside of the temple arm of most glasses and are crucial for finding a frame that fits your face well.

A comfortable and secure fit is more than just a number, though. It’s about how the glasses feel on your face. They shouldn’t slide down your nose, pinch your temples, or leave marks on your skin. If your custom glasses aren’t fitting quite right, don’t hesitate to make adjustments. A good eyewear manufacturer will be able to tweak the fit until it’s perfect.

Partnering with a Trusted Manufacturer

Creating custom eyewear is a collaborative process, and choosing the right manufacturer is key to bringing your vision to life. Communication is essential here—you’ll need to clearly convey your design ideas, preferences, and any specific requirements you have.

It’s important to partner with a reputable and experienced manufacturer who understands the intricacies of eyewear production. They should be able to guide you through the process, offer suggestions based on their expertise, and ensure that the final product meets your expectations.

Another aspect to consider is the production timeline and minimum order quantities (MOQs). Custom eyewear typically takes longer to produce than off-the-shelf options, so plan accordingly. Additionally, some manufacturers may require a minimum order, which could be a factor if you’re ordering for a business or a brand.

Quality Assurance and Certification

Once your custom eyewear is ready, ensuring it meets quality standards is essential. This involves both visual inspection and checking for any certifications that guarantee the eyewear meets safety and quality benchmarks.

Certifications like CE, ANSI, or ISO are crucial for ensuring that your eyewear is made to industry standards. These certifications cover aspects like lens impact resistance, UV protection, and overall durability, giving you peace of mind that your glasses are both safe and high-quality.

Before accepting your custom order, take the time to inspect the eyewear closely. Check the fit, finish, and any personalized details to ensure everything is exactly as you wanted. If something isn’t right, don’t hesitate to request adjustments or corrections.

Caring for Your Custom Eyewear

Once you’ve invested in custom eyewear, it’s important to take care of it properly to ensure it lasts. Cleaning your glasses regularly is key. Use a microfiber cloth and a lens cleaner specifically designed for eyewear to avoid scratching the lenses or damaging any coatings.

When you’re not wearing your glasses, store them in a hard case to protect them from damage. Avoid leaving them in hot environments, like a car on a sunny day, as extreme heat can warp the frames or damage the lenses.

It’s also a good idea to familiarize yourself with the warranty and repair options available for your custom eyewear. Many manufacturers offer warranties that cover defects or damage, giving you added protection for your investment.

Conclusion

Designing premium custom eyewear is a rewarding process that allows you to create glasses tailored to your exact needs and preferences. From identifying your vision and choosing the perfect frame design to selecting the right lenses and ensuring a perfect fit, every step is an opportunity to craft eyewear that’s uniquely yours.

Now that you’re equipped with the knowledge to create your own custom glasses, it’s time to take the next step. Reach out to a trusted eyewear manufacturer today and start bringing your vision to life with custom-designed eyewear that truly stands out.

Manufacturer-Side Custom Brief

What Eyewear Can Custom?

| Type of Premium Glasses | Material & Features | Customization Options |

|---|---|---|

| Luxury Metal Frame Glasses | – High-end materials like titanium, gold plating, platinum, or sterling silver. | – Custom colors and finishes (polished, matte). – Engravings, gemstone inlays. – Personalized nose pads (silicone, leather). – Intricate temple designs. |

| High-End Vintage Style Glasses | – Handcrafted acetate or natural horn materials. | – Frame thickness, color gradients, unique patterns. – Classic rimless or semi-rimless designs. – Customized leather cases, cords, or chains. |

| Luxury Brand Collaborations | – Glasses designed in collaboration with luxury brands (e.g., Gucci, Tom Ford, Cartier). | – Custom frame colors, lens types (blue light blocking, gradient lenses). – Exclusive brand logos or personalized custom elements. |

| Premium Sports Glasses | – High-tech materials like carbon fiber, TR-90 plastic. – Durable, lightweight, impact-resistant. | – Custom lens colors, shapes (e.g., cycling, golf lenses). – Sweat-resistant, non-slip frame designs. – Personal logos or team emblems (e.g., Oakley, Maui Jim). |

| Limited Edition & Exclusive Design | – Limited edition, unique designs with high-end materials. | – Limited edition numbering, special color combinations. – Exclusive branding, custom designs. – Handcrafted, unique details. |

| Luxury Sunglasses | – Premium lenses: optical-grade glass, polarized. – Frames made from rare woods, horn, carbon fiber. | – Custom lens colors, mirrored, gold-plated, or gradient coatings. – Engravings, custom temple designs. – Specialized cases and accessories. |

| High-End Progressive Lens Glasses | – Progressive lenses with seamless near and far vision zones. – High-index, ultra-thin, anti-fatigue coatings. | – Custom frame materials: titanium, precious woods, handcrafted acetate. – Personal signatures, exclusive color combinations. – Unique frame shapes. |

| Premium Children’s Glasses | – Durable TR-90, flexible titanium alloy. – Lightweight, safe, comfortable for kids. | – Design personalization: cartoon elements, color combinations. – Functional lenses: blue light filtering, UV protection. – Personalized engravings. |

What Eyewear Parts can Custom?

Build Any Parts, Tailored Each Detail

Our custom sunglass service covers every detail from design and material selection to production, ensuring that each pair of glasses perfectly matches your taste and requirements. Whether you need special frame designs, unique material choices, or personalized logo printing, we will meticulously craft them for you.

Custom eyewear shapes

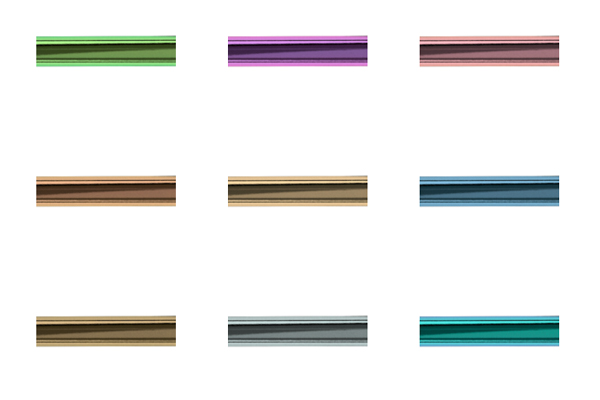

Custom eyewear colors

Custom decoration

Custom eyewear temples

Bespoke eyewear nose pads

OEM eyewear Logo

Personalised eyewear Shapes

- Unique Designs: Create exclusive eyewear shapes tailored to your brand.

- High-Quality Materials:Choose from high-quality acetate, metal, and titanium.

- Trend-Driven Innovation:Stay ahead with fashionable, cutting-edge designs.

- Scalable Production:Meet market demands with our advanced manufacturing.

- Seamless Integration: Easily add custom shapes to your existing product lines.

Custom Eyewear Color

- Brand Consistency: Match colors perfectly to your brand's identity for a cohesive product line.

- Extensive Color Options: Access a wide range of colors, finishes, and effects, including matte, gloss, gradients, and custom prints.

- Trend Adaptability: Quickly adapt to seasonal and market trends with fashionable color options.

- Tailored Preferences: Offer personalized color choices to meet the diverse tastes of your customers.

- Expert Guidance: Receive expert advice and support in selecting and implementing custom colors for your eyewear.

Custom Complexed Decoration

- Engraved Patterns: Intricate, laser-engraved patterns that add a touch of sophistication and detail to the eyewear frame.

- Filigree Designs: Delicate and ornamental designs crafted with fine copper wire, providing a vintage and elegant look.

- Embossed Logos: Custom embossed logos or symbols, creating a distinctive brand identity with a textured feel.

- Hammered Finish: A textured, artisanal finish that offers a unique, handcrafted appearance and a rustic charm.

- Geometric Inlays: Modern, geometric shapes and patterns that add a contemporary and stylish flair to the eyewear design.

Custom Eyewear Temples

- Straight Temples: Simple, straight design for a minimalist look. Ideal for everyday casual wear.

- Skull Temples: Slightly curved behind the ear for a secure fit. Perfect for professional and formal settings.

- Cable Temples: Wrap around the ear, ideal for active wear and sports activities.

- Spring Hinged Temples: Flexible hinges for added comfort and durability. Suitable for daily wear and extended use.

- Hooked Temples: Hook behind the ears for extra stability. Great for children's eyewear or for activities requiring extra stability.

Bespoke Eyewear Nose Pads

- Silicone Nose Pads: Description: Soft and flexible, providing maximum comfort and grip. Occasion: Ideal for daily wear and sports activities. Benefit: Reduces pressure and prevents slipping.

- Adjustable Metal Nose Pads: Description: Made from durable metal, allowing for custom adjustments to fit various nose shapes. Occasion: Suitable for professional and formal eyewear. Benefit: Provides a precise and comfortable fit.

- Acetate Nose Pads: Description: Integrated into the frame, offering a seamless look. Occasion: Perfect for fashion-forward and designer eyewear. Benefit: Ensures a sleek and stylish appearance.

- Gel Nose Pads: Description: Filled with gel for extra cushioning and comfort. Occasion: Great for extended wear and sensitive skin. Benefit: Offers superior comfort and reduces irritation.

- Titanium Nose Pads: Description: Lightweight and hypoallergenic, made from high-quality titanium. Occasion: Best for luxury and high-end eyewear. Benefit: Provides a durable and comfortable fit, ideal for sensitive skin.

OEM Eyewear Logo

- Mould Stamping: High-pressure molds create precise and detailed eyewear designs.

- Zinc Alloy Trims: Decorative metal elements enhance durability and aesthetics.

- Epoxy Logo: Raised, glossy logos provide a three-dimensional, lasting finish.

- Laser Engraving: Lasers etch permanent, detailed designs and text.

- Hot Stamping: Heat and pressure apply luxurious metallic foil imprints.

- Tampor Printing: Silicone pads transfer ink for accurate, multi-color designs on complex shapes.

What are the Custom Process for each Eyewear Series ?

By choosing Eyewearbeyond, you will not only receive exceptional product quality but also enjoy the attentive service of our professional team. We use advanced technology and premium materials to ensure that each customized pair of glasses reflects your unique style and taste.

Everything You Need to Know About Eyewear Manufacturing Cost Sheets

Working in the eyewear industry has many benefits, including creativity, style, and excitement. However, budgeting is another crucial aspect to consider. Manufacturing a pair of

The Critical Role of Injection Molds in Plastic Eyewear Frame Production

I. Introduction Plastic eyewear frames have become a staple in the modern eyewear industry, renowned for their lightweight construction, versatility, and the vast array of

A Comprehensive Guide to Buffalo Horn Frames: How to Make Buffalo Horn Frames?

Buffalo horn glasses are a unique and luxurious choice for eyewear, known for their distinctive beauty and eco-friendly properties. These frames are not only stylish

A Step-by-Step Guide: How to Produce Wooden Sunglasses

Wooden sunglasses have become a must-have accessory for eco-conscious fashionistas and anyone looking to add a touch of nature to their style. Unlike traditional plastic

A step by Step Guide: How Are Metal Eyewear Frames Made?

When it comes to eyewear, metal frames are a go-to choice for anyone who loves a classic, timeless look. Whether it’s the sleek shine of

A Step by Step Guide: How to Make Acetate Eyewear

Acetate frames are well-loved in the eyewear industry for their lightweight, durable, and flexible nature. They’re not just practical but also visually appealing, thanks to

Based on MOQ 300 PCS (Up to 3 colors)

How it Works: to Start Custom Eyewear Manufacturing Process

Overview of how the entire process works In this section. The custom eyewear manufacturing process involves several key steps, each crucial to ensuring both the quality and uniqueness of the final product.

01

DEFINE YOUR IDENTITY

Depend on communications

02

SUBMIT YOUR DESIGN OR SOME IDEA

Depend on communications

03

STARTS TECHNICAL SPECIFICATIONS& DRAWINGS

1-2 weeks

04

QUOTATION & ORDERING

1 Week

05

SAMPLING

45-55 Days

06

PRODUCTION & QUALITY CONTROL

2-3 Months

07

SHIPPING

15days by Air; 1 Month by Sea

Step One

DEFINE YOUR IDENTITY

● What is your retail price range for the products in your collection?

Step Three

STARTS THE TECHNICAL SPECIFICATIONS & DRAWINGS

- We will present you with the perfect products, colors and branding implementation to fit your brand needs.PRODUCT SPECIFICATIONS

● Choose your eye glasses shape● Decide the order QTY● Custom measure frame shape and if needed● Customize temple/tips shape and length● Choose Material (e.g., Acetate / Metal / Titanium)● Choose Glasses Colors/all available● Choose Lens (e.g., Digital HD lenses / Sunglasses Lenses)DETAIL CUSTOMIZATION

● Nose pad type (e.g., Material,W/O LOGO)● Screw type (e.g., Plus or Minus head screw)● Logo (e.g., Mould stamping, zinc alloy trims, epoxy logo, laser, hot stamping, tampor printing…)● Other specifications…● Don’t have a Technical Drawing? We can help you creat your own design drawing.

Step five

SAMPLING

It usually takes 1 month to produce a sample of your design, which we then ship to your address by Air Express freight for approval.

Step seven

SHIPPING

Step Two

SUBMIT YOUR DESIGN OR SOME IDEA

SUBMIT YOUR DESIGN OR SOME IDEA

Step four

QUOTATION & ORDERING

Step six

PRODUCTION&QUALITY CONTROL

Analyze for Eyewear Custom Order Cost

How Much Does It Cost to Have an eyewear protetype Made?

The cost of producing eyeglass frames varies widely, depending on several factors. For a basic frame design in MOQ 300pcs production, the price can range from $3,000 to $5,000. However, for more intricate or custom designs, the cost can exceed $10,000. On average, a standard eyeglass frame that fits a simple design costs around $4000. Understanding these numbers is crucial for planning your production process effectively and optimizing your design early on.

What factors will affect the cost of eyeglass frame production?

The cost of manufacturing eyeglass frames ranges from $300,0 to over $10,000, depending on various factors, including:

- Frame size and complexity:Larger and more complex frame designs require more material and labor, increasing the cost.

- Material selection:The type and quality of materials used in the frames, such as high-grade acetate or titanium, can significantly impact the cost.

- Frame design:The intricacies of the frame design, including hinges, temples, and nose pads, can influence the overall production cost.

- Production volume:Frames designed for high-volume production are built to withstand extensive use, leading to higher initial costs but lower per-unit costs over time.

- Location and supplier:Production costs vary by region. For instance, frames manufactured in China are often more cost-effective than those produced in the US or Europe, due to lower labor and material costs.

- Additional features:Features such as custom engravings, specialized coatings, or adjustable components can increase the cost.

By working closely with a trusted supplier and providing detailed specifications, you can obtain a more accurate estimate for the cost of your eyeglass frame production.

How to Get an eyewear protetype Quote?

Provide Detailed Specifications:

Describe the eyeglass frame’s design, size, material, and intended function. Specify the quantity you need and the desired timeline.

Clearly Define the Frame Requirements: