Top 12 Handmade Eyewear Brands to Watch…

In a Mass-Produced World, Handmade Still Stands Apart When it comes to eyewear, there’s something undeniably…

Wholesale optical frames and sunglasses. Our state-of-the-art factory in China adheres to global standards, including FDA, ISO, CE, ensuring that every product meets stringent quality requirements and customer-specific needs. Our eyewear products are designed and manufactured for a wide range of applications, catering to fashion, optical, and outdoor markets worldwide. We take pride in delivering high-quality, customizable eyewear solutions that have earned the trust of clients across the globe.

A good supplier can not only make you worry-free, but also enable your business to develop sustainably and allow your brand to continuously accumulate reputation for service and quality.

Eyewear Basic Knowledge

1. Introduction

Provide an overview of the eyewear industry and its market potential.

Highlight the importance of understanding basic eyewear knowledge.

2. Basic Components of Eyewear

Explain the main parts of eyewear (e.g., frame, lenses, nose pads, temples, etc.).

Describe the function and role of each component.

3. Different Types of Eyewear

Cover basic knowledge of eyeglasses for nearsightedness, farsightedness, and astigmatism.

Introduce various types of eyewear like sunglasses, blue light glasses, and protective eyewear.

Explain special function eyewear, such as photochromic lenses and polarized lenses.

4. Material Selection for Eyewear

Discuss the types of frame materials (e.g., metal, plastic, titanium) and their pros and cons.

Explain lens materials (e.g., glass, resin, polycarbonate) and their application scenarios.

5. Customization and Design of Eyewear

Outline the process and considerations for customizing eyewear.

Discuss the selection of color, shape, and size, and how to recommend based on customer needs.

Highlight the benefits and market demand for branding and personalized designs.

6. Quality Control and Certification

Key points of quality control in the eyewear manufacturing process.

The importance of industry standards and certifications (e.g., CE, FDA, ISO).

How to ensure products meet market quality requirements.

7. Maintenance and Care of Eyewear

Provide guidance on proper cleaning and maintenance to extend the lifespan of eyewear.

Discuss common eyewear issues and their solutions.

Emphasize the importance of offering maintenance advice to customers.

8. Marketing and Sales Strategies

How to identify the target market and choose the right marketing strategies.

Discuss the combination of online and offline sales channels.

Highlight the importance of customer service and after-sales support.

Eyewear Types Summerize

Classic Optical Eyewear Series

Metal Frame Series: Introduce the characteristics of metal materials like stainless steel, titanium, and aluminum alloy, highlighting durability, lightweight design, and hypoallergenic properties.

Plastic Frame Series: Showcase different types of plastic materials, such as acetate, TR-90, and nylon, emphasizing their advantages in color variety, flexibility, and comfort.

Titanium Frame Series: Dive into the high strength, lightweight, and corrosion-resistant properties of titanium frames, ideal for customers with high material standards.

Natural Material Frame Series: Introduce frames made from natural materials like wood, bamboo, and horn, highlighting their uniqueness and eco-friendliness, appealing to customers who value sustainability.

Mixed Material Frame Series: Combine the benefits of different materials, such as metal with plastic or titanium with wood, offering innovative designs and exceptional comfort, suited for customers seeking personalization and high quality.

3. Sunglasses Series

Classic Sunglasses Series: Discuss classic styles like aviators, cat-eye, and wayfarers, suitable for a wide audience.

Polarized Sunglasses Series: Introduce the function of polarized lenses and their benefits in reducing glare and enhancing visual clarity, ideal for outdoor activities and driving.

Photochromic Sunglasses Series: Explain the materials used in photochromic lenses, such as photochromic glass or resin, and their ability to automatically adjust tint in different lighting conditions, making them suitable for all-day wear.

Lens Material Options: Discuss the materials used in sunglasses lenses, such as glass, CR-39, and polycarbonate, highlighting the advantages like scratch resistance, impact resistance, and lightweight design.

Frame Material Options: Introduce frame materials suitable for sunglasses, such as stainless steel, acetate, TR-90, and carbon fiber, emphasizing their features in terms of weight, comfort, and durability.

4. Functional Eyewear Series

Blue Light Blocking Glasses Series: Highlight materials used in blue light blocking lenses, such as resin and advanced blue light filtering coatings, designed for long hours of screen use to protect eyes from harmful blue light.

Protective Eyewear Series: Introduce the specialized materials used in protective eyewear, like impact-resistant polycarbonate and reinforced glass, making them suitable for industrial, laboratory, and construction environments.

Sports Eyewear Series: Discuss the special materials used in sports eyewear, such as high-strength polycarbonate lenses and anti-slip rubber frames, emphasizing their impact resistance, lightweight design, and comfort, suitable for various sports scenarios.

5. Children’s Eyewear Series

Children’s Optical Glasses: Introduce materials commonly used in children’s eyewear, such as flexible TR-90 and lightweight, durable silicone, designed to be robust yet comfortable for daily wear.

Children’s Sunglasses: Emphasize the materials used in children’s sunglasses lenses, such as polycarbonate with UV protection coatings, ensuring full protection against harmful sun rays.

Adjustable Children’s Glasses: Introduce frames made from adjustable materials like memory metal and flexible plastics, designed to grow with the child, providing long-term comfort and durability.

6. High-End Custom Series

Luxury Custom Frames: Explore the use of high-end materials like pure titanium, 24K gold plating, and exotic woods to create luxurious custom frames that showcase uniqueness and personal style, ideal for high-end clientele.

Personalized Lens Options: Offer a variety of premium lens material choices, such as anti-reflective coatings, blue light filters, and ultra-thin high-index lenses, tailored to meet specific customer needs and provide superior visual experience.

Branding and Embellishment Design: Introduce high-end craftsmanship and materials used in custom eyewear, such as hand-inlaid gemstones and branded logos, providing a unique customization experience that highlights brand identity.

7. Sustainable and Eco-Friendly Series

Eco-Friendly Material Eyewear: Introduce eyewear made from recycled or biodegradable materials, such as recycled plastic and eco-friendly acetate, aligning with green environmental principles and appealing to eco-conscious customers.

Recyclable Frame Series: Emphasize the recyclability of products, using renewable resources and low-carbon footprint production processes, suited for customers with strong environmental awareness.

Low-Carbon Production Process: Discuss the use of energy-efficient production technologies and sustainable materials, reducing carbon emissions during manufacturing, and highlighting the company’s commitment to environmental responsibility.

8. Conclusion

1. Introduction

Introduce the importance of LOGOs in eyewear branding.

Provide a brief overview of the applications of different LOGO processes.

2. Engraving Processes

Laser Engraving: Introduce the features and benefits of laser engraving technology, suitable for metal and plastic frames.

Mechanical Engraving: Discuss the traditional mechanical engraving process and its application in certain high-end products.

3. Printing Processes

Screen Printing: Explain how screen printing technology can be applied to frames or temples, suitable for plastic and metal materials.

Heat Transfer Printing: Describe the operation of heat transfer printing and its application in complex patterns and multi-color LOGOs.

4. Electroplating and Metal Inlay

Electroplated LOGO: Introduce how electroplating technology applies the LOGO to metal frames, enhancing brand recognition.

Metal Inlay LOGO: Discuss the process of inlaying metal pieces into frames, suitable for high-end and luxury brand designs.

5. Labeling and Tags

Adhesive Labels: Describe the use of adhesive labels and their application on lenses or frames.

Metal Tags: Introduce the production and installation of metal tags, emphasizing their use in high-end products.

6. Painting and Hand-Painted Finishing

Hand-Painted LOGO: Explain the uniqueness of hand-painted LOGOs and their application in highly artistic products.

Automated Spray LOGO: Discuss the efficiency and consistency of automated spray technology in mass production.

7. UV Printing

UV Printing Process: Introduce how UV printing can quickly and accurately print LOGOs on various materials, suitable for multiple frame materials.

8. Stone Setting and Inlay Techniques

Gemstone Inlaid LOGO: Describe the process of embedding gemstones or other decorative elements in high-end eyewear to enhance the luxury appeal of the LOGO.

Plastic Inlay: Discuss the methods for inlaying different materials into plastic frames for LOGO creation.

9. Choosing the Right LOGO Process

Discuss how to choose the most appropriate LOGO process based on brand positioning, budget, materials, and product style.

10. Conclusion

Emphasize the role of LOGO processes in brand building.

Encourage wholesalers and retail store owners to collaborate with manufacturers to select the best LOGO process.

Introduction to Private Label Eyewear: What You Need to Know

Choosing the Right Manufacturer for Private Label Eyewear

Designing Your Private Label Eyewear Collection

Material Selection for Private Label Eyewear: What Works Best

Customizing Eyewear Frames: Colors, Shapes, and Finishes

Lens Options for Private Label Eyewear: UV Protection, Polarization, and More

Branding and Packaging: Making Your Private Label Stand Out

Navigating Quality Control in Private Label Eyewear Production

Legal Aspects of Private Labeling: Trademarks and Compliance

Marketing Strategies for Launching a Private Label Eyewear Line

1. Introduction

Welcome to the fascinating world of eyewear! Whether you’re running a business, designing your own line, or just curious about what makes those stylish frames and lenses tick, you’re in the right place. The eyewear industry is huge and growing every year, with global revenues expected to hit over $170 billion by 2028. That’s a lot of glasses!

But here’s the thing: To really make your mark in this industry, or just to be a more informed consumer, you need to know the basics. Understanding the ins and outs of eyewear will help you make smarter decisions, offer better products, and keep your customers happy. So, let’s dive in and break it all down—from the basic parts of glasses to the latest trends in design and materials.

2. Basic Components of Eyewear

Let’s start with the basics. Eyewear might seem simple, but it’s made up of several key components, each playing a crucial role in how the glasses fit, feel, and function.

The Frame

The frame is the structure that holds everything together. It’s what gives the glasses their shape and style. But it’s not just about looks—the frame also needs to be sturdy enough to hold the lenses in place while being comfortable to wear.

Lenses

The lenses are the most important part of any eyewear. Whether they’re prescription lenses to help you see better, or tinted lenses for sunglasses, their job is to provide clear vision and protect your eyes. Lenses come in a variety of materials, each with its own pros and cons (more on that later).

Nose Pads

Ever notice those little pads that rest on your nose? They’re called nose pads, and they play a big role in comfort. They help distribute the weight of the glasses evenly across your nose, preventing them from sliding down.

Temples

The temples are the arms of the glasses that stretch from the lenses to behind your ears. They’re essential for keeping the glasses securely on your face. They also come in different lengths and styles to fit various head shapes and sizes.

Hinges

Hinges connect the temples to the frame and allow the temples to fold inwards. They need to be strong and flexible to withstand daily use without breaking.

Bridge

The bridge is the part that sits across the nose and connects the two lenses. It’s crucial for ensuring the glasses fit well on your face. Different bridges suit different nose shapes, so it’s important to choose one that feels comfortable.

Component | Description | Function |

Frame | The structure that holds the lenses | Provides support and style |

Lenses | The transparent parts you see through | Corrects vision or protects eyes |

Nose Pads | Pads that rest on your nose | Ensures comfort and fit |

Temples | The arms of the glasses | Keeps glasses in place |

Hinges | Connects the frame to the temples | Allows temples to fold |

Bridge | Sits on the nose, connects lenses | Ensures proper fit |

3. Different Types of Eyewear

There are so many different types of eyewear out there, each serving a specific purpose. Let’s break down the most common ones.

Eyeglasses for Vision Correction

If you’ve ever worn glasses, you know they’re not all the same. Here are the main types of corrective lenses:

Nearsightedness (Myopia): These glasses have concave lenses that help you see distant objects more clearly.

Farsightedness (Hyperopia): Convex lenses are used here to help you see things up close.

Astigmatism: If your eyes are shaped more like a football than a basketball, you might have astigmatism. Special lenses with cylindrical shapes correct this condition.

Sunglasses

Sunglasses are a must-have for sunny days, but they do more than just look cool:

Polarized Sunglasses: These lenses cut down on glare from reflective surfaces like water or car hoods. Great for driving or spending time outdoors.

Photochromic Lenses: These lenses change their tint based on light conditions. They’re perfect for people who move between indoors and outdoors a lot.

Special Function Eyewear

There’s eyewear designed for more specific needs, too:

Blue Light Glasses: These are great for people who spend a lot of time in front of screens. They filter out the blue light that can cause eye strain and mess with your sleep.

Protective Eyewear: Whether you’re working in a lab or playing sports, protective eyewear shields your eyes from impacts, dust, and other hazards.

Type of Eyewear | Description |

Nearsightedness Glasses | Helps with seeing distant objects clearly |

Farsightedness Glasses | Aids in seeing close-up objects better |

Sunglasses | Protects eyes from UV rays and glare |

Blue Light Glasses | Filters blue light from screens |

Photochromic Glasses | Changes tint with light exposure |

Protective Eyewear | Shields eyes from physical hazards |

4. Material Selection for Eyewear

The materials used in eyewear frames and lenses can make a big difference in comfort, durability, and style.

Frame Materials

Metal Frames

Stainless Steel: Durable, corrosion-resistant, and hypoallergenic—perfect for everyday wear.

Titanium: Super strong, lightweight, and doesn’t corrode. It’s a premium material often used in high-end eyewear.

Aluminum: Lightweight and flexible, but not as strong as titanium or stainless steel.

Plastic Frames

Acetate: A popular choice because it’s lightweight, hypoallergenic, and comes in lots of colors and patterns.

TR-90: A tough thermoplastic that’s flexible and lightweight—ideal for sports glasses.

Nylon: Durable and resistant to temperature changes, often used in performance eyewear.

Natural Materials

Wood: Each frame is unique, offering a natural, eco-friendly option, though it requires a bit more care.

Bamboo: Strong, lightweight, and sustainable, bamboo frames are a hit with environmentally conscious customers.

Horn: Luxurious and natural, horn frames offer a unique look but are more delicate.

Material Type | Pros | Cons |

Metal | Durable, hypoallergenic | Can be heavier and more expensive |

Plastic | Lightweight, colorful | Less durable, prone to scratches |

Natural | Eco-friendly, unique | Needs more care, can be pricier |

Lens Materials

Glass Lenses

Pros: Extremely clear and scratch-resistant.

Cons: Heavier and can break more easily.

Resin (CR-39) Lenses

Pros: Lightweight and affordable with good optical clarity.

Cons: Not as impact-resistant as polycarbonate.

Polycarbonate Lenses

Pros: Super impact-resistant and lightweight—perfect for sports or kids.

Cons: More prone to scratches unless coated.

Lens Material | Pros | Cons |

Glass | Clear, scratch-resistant | Heavier, can break |

Resin (CR-39) | Lightweight, affordable | Less impact-resistant |

Polycarbonate | Impact-resistant, UV protection | Scratches easily without coating |

5. Customization and Design of Eyewear

Personalizing eyewear is a great way to stand out in a crowded market. Here’s how you can do it.

Customization Process

Color: Choose colors that match your brand or appeal to your target customers. Bright colors for a youthful audience, classic tones for professionals—the choice is yours.

Shape and Size: Consider the shape of the frame and its size to ensure it fits your demographic. Round frames might appeal to one group, while rectangular might suit another.

Material: Depending on the style and function, pick the right material. For high-end designs, titanium or acetate might be the way to go.

Tailoring Eyewear to Customer Needs

Understanding what your customers need is key. If they’re active, suggest lightweight, durable materials like TR-90. For those who want something trendy, offer stylish acetate frames in the latest colors.

Customization Aspect | Considerations |

Color | Align with brand or customer preferences |

Shape and Size | Fit for the target demographic |

Material | Choose based on style and function |

Why Branding and Personalization Matter

In today’s market, people want products that reflect their personality. Offering custom branding, like logo placements or engravings, can add that personal touch customers love.

6. Quality Control and Certification

Quality is everything when it comes to eyewear. Here’s how to make sure your products meet the highest standards.

Key Quality Control Steps

Material Checks: Make sure the materials used are up to snuff. Inspect the frames and lenses for any defects or inconsistencies.

Craftsmanship: The assembly process should be flawless, with perfectly aligned hinges and smooth edges.

Durability Testing: Test the glasses to make sure they can handle everyday wear and tear. This might include dropping them from different heights or applying pressure to the frame.

Industry Standards and Certifications

Certifications ensure that your eyewear meets international safety and quality standards. Some of the key ones include:

CE Marking: Required in the European Union, it shows that your product meets health, safety, and environmental protection standards.

FDA Approval: Necessary for products sold in the United States, ensuring they’re safe and effective.

ISO Certification: A global standard for quality management, it ensures consistent product quality.

Certification | Purpose | Region |

CE Marking | EU safety, health, and environmental standards | European Union |

FDA Approval | Safety and effectiveness | United States |

ISO Certification | Quality management standards | Global |

Meeting Market Quality Requirements

To ensure your products always meet market demands, regular quality audits and updates to your processes are essential. Partnering with third-party testing agencies can help you stay compliant with the latest standards.

7. Maintenance and Care of Eyewear

Eyewear, like anything else, needs a little TLC to keep it looking good and functioning well.

Cleaning and Maintenance Tips

Cleaning: Always use a microfiber cloth and lens cleaner. Avoid using your shirt or paper towels, as they can scratch the lenses.

Storage: When not in use, keep your glasses in a hard case. This protects them from getting crushed or scratched.

Adjustments: Check the fit regularly. If the glasses start to slide down your nose, they might need a quick adjustment.

Common Eyewear Issues and How to Fix Them

Scratches on Lenses: Depending on the severity, you might be able to polish out minor scratches, but deeper ones will likely need lens replacement.

Loose Screws: Tighten them with a small screwdriver. If they keep loosening, a drop of thread-locker can help.

Bent Frames: Carefully adjust them back into shape, or take them to a professional.

Issue | Solution |

Scratched Lenses | Replace or polish |

Loose Screws | Tighten or use thread-locker |

Bent Frames | Adjust or seek professional help |

Why You Should Educate Customers on Maintenance

Helping your customers understand how to care for their eyewear not only extends the life of the product but also builds trust and loyalty. Consider offering cleaning kits or sending out care tips after purchase.

8. Marketing and Sales Strategies

Selling eyewear isn’t just about having a great product—it’s about getting that product in front of the right people.

Identifying Your Target Market

Knowing your audience is the first step. Are you targeting young professionals, athletes, or eco-conscious consumers? Once you know who you’re selling to, you can tailor your marketing efforts to speak directly to them.

Online and Offline Sales Channels

To reach the widest audience, you need to be everywhere your customers are.

Online Sales: Use platforms like Shopify or Amazon to reach customers who prefer shopping online. Enhance the experience with features like virtual try-ons or detailed customer reviews.

Offline Sales: Don’t underestimate the power of physical stores or pop-up shops. Many customers still want to try before they buy, especially with something as personal as eyewear.

Customer Service and After-Sales Support

Great customer service is what turns a one-time buyer into a loyal customer. Offer warranties, repair services, and follow-up support to ensure your customers are happy with their purchase.

Sales Strategy | Description |

Online Sales | Leverage e-commerce and social media |

Offline Sales | Provide in-person experiences |

Customer Service | Offer warranties, repairs, and follow-up support |

9. Eyewear Types Summary

Let’s wrap up by summarizing the different types of eyewear out there.

Classic Optical Eyewear Series

Metal Frame Series: Durable, lightweight, and hypoallergenic—perfect for everyday wear.

Plastic Frame Series: Flexible and colorful, offering great comfort and style.

Titanium Frame Series: Ultra-strong and corrosion-resistant, ideal for high-end eyewear.

Natural Material Frame Series: Unique and eco-friendly, appealing to customers who care about sustainability.

Mixed Material Frame Series: Combines the best of different materials for innovative designs and high comfort.

Sunglasses Series

Classic Sunglasses Series: Timeless designs like aviators and wayfarers that never go out of style.

Polarized Sunglasses Series: Perfect for reducing glare, ideal for outdoor activities.

Photochromic Sunglasses Series: Lenses that adjust to lighting conditions, great for all-day wear.

Eyewear Series | Description |

Classic Optical Series | Metal, plastic, titanium, natural, and mixed material frames for varied preferences |

Sunglasses Series | Classic, polarized, and photochromic sunglasses for different uses |

Functional Eyewear Series

Blue Light Blocking Glasses Series: Essential for those who spend long hours in front of screens.

Protective Eyewear Series: Designed to protect eyes in industrial, lab, or sports environments.

Sports Eyewear Series: Built for impact resistance, with materials like polycarbonate and anti-slip frames.

Children’s Eyewear Series

Children’s Optical Glasses: Made from flexible, durable materials like TR-90 and silicone.

Children’s Sunglasses: Featuring polycarbonate lenses with UV protection.

Adjustable Children’s Glasses: Frames that grow with the child, offering long-term comfort.

Functional Series | Description |

Blue Light Glasses | Protects against blue light |

Protective Eyewear | Impact-resistant for industrial and sports use |

Children’s Eyewear | Durable, flexible, and designed for kids |

High-End Custom Series

Luxury Custom Frames: Made from premium materials like pure titanium and 24K gold plating.

Personalized Lens Options: High-index lenses, anti-reflective coatings, and blue light filters.

Branding and Embellishment Design: Custom logos, hand-inlaid gemstones, and other luxury features.

Sustainable and Eco-Friendly Series

Eco-Friendly Material Eyewear: Made from recycled or biodegradable materials, like eco-friendly acetate.

Recyclable Frame Series: Designed for recyclability with a low-carbon production process.

Low-Carbon Production Process: Energy-efficient manufacturing with a focus on reducing carbon emissions.

High-End and Sustainable Series | Description |

Luxury Custom Frames | Premium materials and personalized designs |

Eco-Friendly Eyewear | Sustainable materials and low-carbon processes |

10. Conclusion

Whether you’re diving into the eyewear industry or just want to be a more informed shopper, understanding the basics of eyewear is key. From the different components that make up a pair of glasses to the materials and designs that set them apart, there’s a lot to learn. By getting to know these details, you’ll be better equipped to make smart choices—whether that’s creating your next product line or simply picking out your next pair of shades.

1. Introduction

In the world of fashion and accessories, eyewear stands out as a unique blend of functionality and style. A key element that elevates eyewear from a simple tool to a fashion statement is the LOGO. For brands, especially those in the private label business, the LOGO is not just a mark—it’s a powerful symbol of identity and trust. It’s what your customers recognize and what sets your products apart from countless others on the market.

Branding your eyewear with a distinctive LOGO can significantly boost brand recognition, loyalty, and perceived value. But with so many options available, how do you choose the right method to apply your LOGO? From engraving and printing to more luxurious options like electroplating and gemstone inlay, each process has its own advantages and is suitable for different materials and branding styles. This comprehensive guide will walk you through the various LOGO application methods so you can make an informed decision for your private label eyewear.

2. Engraving Processes

Laser Engraving

Laser engraving is a modern, precise technique that’s widely used for applying LOGOs to both metal and plastic eyewear frames. The process involves using a high-powered laser to etch the LOGO directly onto the frame.

Features and Benefits:

Precision: Laser engraving allows for extremely detailed and intricate designs, perfect for small or complex LOGOs.

Durability: The engraved LOGO is permanent and resistant to wear and tear, ensuring it lasts for the lifetime of the eyewear.

Versatility: This method works well on a variety of materials, including metal, plastic, and even wood.

Laser engraving is ideal for brands looking for a subtle, yet sophisticated LOGO that won’t fade over time. It’s particularly popular for premium eyewear collections where detail and durability are paramount.

Mechanical Engraving

Mechanical engraving is a more traditional method that involves physically carving the LOGO into the frame using a mechanical tool. While this process is less common today due to the rise of laser technology, it still holds a special place in high-end eyewear manufacturing.

Applications:

High-End Products: Mechanical engraving is often used for luxury eyewear, where the depth and texture of the LOGO add a sense of craftsmanship and exclusivity.

Tactile Appeal: The engraved LOGO provides a textured feel that can enhance the tactile experience of the product, giving it a unique and premium finish.

Mechanical engraving is best suited for brands that want to emphasize traditional craftsmanship and create a LOGO that feels both timeless and luxurious.

Engraving Type | Features | Best For |

Laser Engraving | High precision, durable, versatile | Premium collections, intricate LOGOs |

Mechanical Engraving | Traditional, tactile, luxurious | High-end, luxury eyewear with a classic touch |

3. Printing Processes

Screen Printing

Screen printing is one of the most common methods used to apply LOGOs to eyewear, particularly on plastic and metal frames. This technique involves creating a stencil (or “screen”) of the LOGO and then using it to apply ink directly onto the frame.

How It Works:

Application: The screen is pressed against the frame, and ink is spread across the screen, passing through the stencil to leave the LOGO on the frame.

Versatility: Screen printing can be used on both plastic and metal materials, making it a versatile choice for various eyewear designs.

Benefits:

Cost-Effective: Ideal for large production runs, screen printing offers a cost-effective solution for applying LOGOs to multiple units.

Bold Colors: This method is particularly effective for bold, single-color LOGOs that need to stand out on the frame.

Screen printing is perfect for brands looking to produce large quantities of eyewear with a simple, bold LOGO that makes a strong visual impact.

Heat Transfer Printing

Heat transfer printing is a technique that allows for the application of complex patterns and multi-color LOGOs onto eyewear frames. The process involves printing the LOGO onto a special film, which is then transferred onto the frame using heat and pressure.

Operation:

Complex Designs: Heat transfer is ideal for LOGOs with multiple colors or intricate designs that are difficult to achieve with traditional screen printing.

Durability: The heat application ensures that the LOGO adheres firmly to the frame, making it resistant to wear and fading.

Applications:

Plastic Frames: This process works particularly well on plastic materials, where the heat can effectively transfer the design.

Multi-Color LOGOs: If your brand’s LOGO involves detailed patterns or multiple colors, heat transfer printing is a great choice.

Heat transfer printing is the go-to method for brands that want to showcase intricate, colorful LOGOs that pop against the frame’s material.

Printing Type | Features | Best For |

Screen Printing | Cost-effective, bold colors | Large runs, simple and bold LOGOs |

Heat Transfer Printing | Ideal for complex, multi-color LOGOs | Detailed, colorful designs on plastic frames |

4. Electroplating and Metal Inlay

Electroplated LOGO

Electroplating is a sophisticated process where a metal LOGO is deposited onto the surface of a frame using an electric current. This technique is primarily used on metal frames to create a LOGO that is both visually striking and durable.

Features:

Enhanced Recognition: The shiny, metallic finish of an electroplated LOGO not only makes it stand out but also enhances brand recognition.

Durability: Electroplated LOGOs are highly resistant to wear, making them perfect for high-end, everyday eyewear.

Application:

Metal Frames: This process is best suited for metal frames, where the electroplated LOGO can seamlessly integrate into the design.

Electroplated LOGOs are ideal for luxury eyewear brands looking to add a touch of elegance and sophistication to their products.

Metal Inlay LOGO

Metal inlay is a process where a metal LOGO is embedded directly into the frame material, creating a LOGO that is flush with the surface of the frame. This technique is particularly popular in high-end and luxury eyewear.

Process:

Inlay Technique: The LOGO is precisely cut from a metal sheet and then embedded into the frame material, creating a seamless integration.

Luxury Appeal: The metal inlay LOGO adds a premium, handcrafted feel to the eyewear, making it perfect for luxury brands.

Best For:

High-End Designs: This method is ideal for luxury and bespoke eyewear where quality and craftsmanship are paramount.

Metal inlay LOGOs are perfect for brands that want to emphasize exclusivity and attention to detail in their eyewear collections.

Method | Features | Best For |

Electroplated LOGO | Shiny, durable, enhances recognition | High-end, metal frames |

Metal Inlay LOGO | Luxurious, seamless, handcrafted look | Luxury, bespoke eyewear designs |

5. Labeling and Tags

Adhesive Labels

Adhesive labels offer a quick and versatile way to add a LOGO to eyewear. These labels can be applied to both lenses and frames and are often used for temporary branding, such as promotional campaigns or limited-edition releases.

Features:

Flexibility: Adhesive labels are easy to apply and remove, making them suitable for temporary or seasonal branding.

Customization: They can be printed in various shapes, sizes, and colors to match your branding needs.

Applications:

Promotional Products: Ideal for limited-time offers or special editions where the LOGO may need to be updated frequently.

Lenses and Frames: Can be applied to both lenses and frames, offering flexibility in placement.

Adhesive labels are a great choice for brands looking for a cost-effective and flexible solution for temporary LOGO application.

Metal Tags

Metal tags are a more permanent and upscale option for adding a LOGO to eyewear. These tags are typically attached to the frame or temples and can feature detailed engravings or embossed designs.

Production and Installation:

High-End Appeal: Metal tags add a touch of luxury and exclusivity to eyewear, making them ideal for premium products.

Durability: The metal material ensures that the LOGO remains intact and visible for the life of the eyewear.

Best For:

Luxury Brands: Metal tags are perfect for high-end products where branding needs to reflect quality and prestige.

Metal tags are an excellent choice for brands that want to emphasize quality and create a lasting impression with their LOGO.

Labeling Type | Features | Best For |

Adhesive Labels | Flexible, customizable, temporary | Promotional or limited-edition products |

Metal Tags | Permanent, high-end appeal | Luxury eyewear, long-term branding |

6. Painting and Hand-Painted Finishing

Hand-Painted LOGO

For a truly unique and artistic touch, hand-painted LOGOs are an excellent choice. This process involves manually applying the LOGO to the frame, allowing for a high degree of creativity and customization.

Features:

Artistic Appeal: Hand-painted LOGOs can be tailored to create one-of-a-kind designs that stand out in the market.

Exclusivity: Each LOGO is individually crafted, adding to the exclusivity and luxury of the product.

Applications:

Artistic Products: Ideal for limited-edition or bespoke eyewear that demands a personal and artistic touch.

Hand-painted LOGOs are perfect for brands that want to create a unique and highly artistic product that resonates with collectors and connoisseurs.

Automated Spray LOGO

Automated spray technology offers a more efficient way to apply LOGOs in mass production. This process uses a machine to spray the LOGO onto the frame, ensuring consistency and precision across large batches.

Efficiency:

Mass Production: The automated process is ideal for large-scale production runs where consistency and speed are crucial.

Precision: The spray technology ensures that each LOGO is applied with the same precision and quality, regardless of the volume.

Best For:

Large Batches: Perfect for brands that need to produce a high volume of eyewear with consistent branding.

Automated spray LOGOs are the go-to choice for brands focused on efficiency and consistency in mass production.

Painting Method | Features | Best For |

Hand-Painted LOGO | Artistic, unique, highly customizable | Limited-edition, artistic eyewear |

Automated Spray LOGO | Efficient, consistent, ideal for mass production | Large-scale production, consistent quality |

7. UV Printing

UV Printing Process

UV printing is a state-of-the-art technique that allows for the quick and accurate application of LOGOs on a wide range of materials. The UV light cures the ink instantly, creating a LOGO that is both vibrant and durable.

Features:

Versatility: UV printing works well on various frame materials, including plastic, metal, and even wood.

Precision: The process allows for high-resolution printing, making it possible to apply even the most detailed LOGOs.

Applications:

Multi-Material Frames: Suitable for brands that work with different materials and need a LOGO application method that can handle all of them.

Detailed Designs: Ideal for intricate LOGOs that require precision and clarity.

UV printing is perfect for brands that need a versatile and reliable method to apply high-quality LOGOs on different materials.

8. Stone Setting and Inlay Techniques

Gemstone Inlaid LOGO

For luxury brands looking to make a bold statement, gemstone inlay is an exquisite option. This process involves setting small gemstones into the frame to create a dazzling LOGO.

Process:

Luxury Appeal: Gemstone inlay adds a touch of opulence and exclusivity, making the eyewear a true luxury item.

Customization: Brands can choose from a variety of gemstones to match their branding and design preferences.

Best For:

High-End Products: Gemstone inlay is perfect for limited-edition or bespoke eyewear that aims to captivate luxury buyers.

Plastic Inlay

Plastic inlay is a method where different materials are embedded into plastic frames to create a LOGO. This can include colored plastics, metals, or even other decorative elements.

Process:

Versatility: Plastic inlay allows for a wide range of design possibilities, enabling brands to create truly unique LOGOs.

Durability: The inlay is protected by the surrounding plastic, making it durable and resistant to wear.

Best For:

Creative Designs: Ideal for brands looking to experiment with different materials and create innovative, eye-catching LOGOs.

Inlay Technique | Features | Best For |

Gemstone Inlaid LOGO | Luxurious, customizable, highly exclusive | High-end, limited-edition eyewear |

Plastic Inlay | Versatile, durable, innovative | Creative, eye-catching LOGO designs |

9. Choosing the Right LOGO Process

Selecting the right LOGO process for your private label eyewear depends on several factors:

Brand Positioning: Luxury brands might opt for gemstone inlay or metal tags, while more affordable lines could use screen printing or adhesive labels.

Budget: More intricate processes like mechanical engraving or gemstone inlay will be more expensive, so it’s essential to balance cost with brand image.

Materials: Some processes work better with specific materials—UV printing is versatile across many, while electroplating is best for metal.

Product Style: The overall style of your eyewear should complement the LOGO process. A minimalist design might benefit from laser engraving, while a bold, colorful style could be enhanced with heat transfer printing.

Consideration | Best LOGO Process |

Luxury Branding | Gemstone Inlay, Metal Inlay, Electroplated LOGO |

Cost-Effective Solutions | Screen Printing, Adhesive Labels |

Multi-Material Use | UV Printing, Plastic Inlay |

High-Volume Production | Automated Spray LOGO, Screen Printing |

| Description | Applicable Materials | Advantages | Common Applications |

Silk Screen Printing | Uses a mesh stencil to apply ink to the surface of materials, allowing for multi-color designs | Plastic, metal, wood, lenses, etc. | Vibrant colors, suitable for mass production, clear patterns | Custom patterns, brand logos, decorative designs |

Hot Stamping | Uses heated molds to press metallic foil or plastic film onto the material surface for a glossy effect | Plastic, metal, leather, etc. | High-end visual effect, strong durability, suitable for premium branding | High-end eyewear logos, decorative designs, special pattern treatments |

Laser Engraving | Uses lasers to precisely engrave patterns or text on various materials, often for high-precision customization | Metal, wood, plastic, lenses, etc. | High precision, long-lasting, wear-resistant | High-end brand logos, personalized customization, intricate patterns |

Metal Logo Implementation | Embeds metal logos into the eyewear frame or temples, enhancing brand recognition and premium feel | Plastic, metal, wood | Strong premium feel, enhances brand value, outstanding visual effect | High-end brand eyewear, special edition products |

UV Patch | Uses UV printing technology to apply multi-color patterns to eyewear surfaces, suitable for complex designs and gradients | Plastic, metal, wood | Multi-color printing, fine patterns, suitable for complex designs | Custom patterns, brand logos, artistic designs |

Crystal Gel Lettering | Uses transparent crystal gel to apply three-dimensional letters or logos to the eyewear surface, enhancing visual effects | Plastic, metal, wood | Strong 3D effect, good transparency, adds texture | High-end brand logos, special custom eyewear |

3D Printing | Uses 3D printing technology to directly manufacture frames or parts, suitable for complex shapes and unique designs | Plastic, resin | High design freedom, suitable for customized production, rapid prototyping | Custom designs, prototyping, personalized eyewear |

This table helps custom eyewear and wholesale customers quickly understand the characteristics and application scenarios of various printing and marking technologies, enabling better choices for product customization and branding.

10. Conclusion

The LOGO on your eyewear is a crucial part of your brand’s identity. It’s what your customers will see and remember, so it’s essential to choose the right process to apply it. From engraving and printing to more luxurious methods like gemstone inlay, each LOGO application process has its own unique benefits and is suited to different brand positions and product types.

By collaborating closely with your manufacturer and considering factors like budget, material, and brand positioning, you can select the LOGO process that best reflects your brand’s values and enhances the appeal of your products. With the right LOGO process, your private label eyewear will stand out in a competitive market, making a lasting impression on customers and building a strong brand identity.

When considering private labeling eyewear with your brand’s LOGO, understanding the associated costs is crucial. Depending on the method, materials, and complexity, the cost can vary significantly. For instance, a basic screen-printed LOGO on plastic frames might cost you between $0.5 to $1 for each pc, whereas more intricate processes like gemstone inlay on luxury frames can exceed $1. On average, a standard private label LOGO application, such as laser engraving on metal frames, might cost around $5,0-$1000. Knowing these figures is essential to plan your branding strategy effectively and optimize your LOGO design from the start.

What Factors Will Affect the Cost of Private Labeling Eyewear LOGOs?

The cost of applying a private label LOGO to eyewear can range from $1,000 to over $10,000, depending on various factors. Here are some key elements that can influence the cost:

LOGO Size and Complexity: Larger and more intricate LOGOs require more detailed work, which increases the cost.

Material Selection: The type and quality of the frame and LOGO materials can impact the cost. For example, high-end metals or gemstones will be more expensive than plastic or standard inks.

LOGO Application Method: Different processes, such as laser engraving, screen printing, or metal inlay, vary in cost depending on the technology and labor involved.

Production Volume: Higher production volumes can reduce the per-unit cost but may involve a higher initial investment.

Location and Supplier: The cost of LOGO application can vary significantly depending on where it’s done. For example, production in China might be more affordable than in the US or Europe due to lower labor and material costs.

Additional Features: Extras like multi-color printing, UV protection, or hand-painted finishes can increase the overall cost.

Breakdown of Cost Factors

Factor | Description | Percentage Share |

LOGO Size and Complexity | Larger and more complex LOGOs require more material and labor, increasing the cost. | 20% |

Material Selection | High-quality materials like titanium or gemstones are more expensive than basic plastics or inks. | 20% |

LOGO Application Method | The choice of method, from simple printing to advanced inlay, significantly affects the cost. | 20% |

Production Volume | Higher volumes reduce the per-unit cost but require more upfront investment. | 10% |

Location and Supplier | Production costs vary by region, with lower costs often found in countries with cheaper labor. | 10% |

Additional Features | Special features like multi-color or UV printing add to the overall cost. | 10% |

Profit Margins | Manufacturers include a profit margin in their pricing, which contributes to the final cost. | 10% |

How to Get an Accurate LOGO Application Quote?

To get an accurate quote for applying your private label LOGO on eyewear, follow these steps:

Start by giving the supplier a clear description of your LOGO—its size, colors, and materials. Specify the type of frames you want the LOGO on, whether plastic, metal, or a combination of materials.

Explain the type of LOGO you want: engraved, printed, inlaid, etc. Specify any desired finishes, such as polished, matte, or brushed, and any special requirements like UV protection or waterproofing.

Tell the supplier how many units you plan to produce and your desired timeline. This helps them estimate how long the process will take and when maintenance or additional orders might be necessary.

Provide a 3D file or design sketches of your LOGO. Make sure to communicate any specific requirements, such as limited space on the frame or material restrictions.

Give the supplier precise dimensions and tolerances for your LOGO placement. This ensures that the design is applied correctly and meets your standards.

Ask the supplier for a quote that breaks down the costs, including:

Design and application fees

Tooling costs (e.g., molds, stencils, or engraving tools)

Per-unit production costs (e.g., labor, materials, overhead)

Any additional costs (e.g., maintenance, repairs)

Examine the quote carefully to ensure it includes everything you need and meets your budget. If something isn’t clear, ask the supplier for clarification.

Before committing to a large order, request a sample or prototype to verify that the LOGO is applied correctly and meets your expectations.

Discuss the quote with the supplier and negotiate the terms if necessary to ensure both parties are on the same page.

Research the supplier’s reputation and experience in applying LOGOs to eyewear. Ensure they have experience with similar materials, production volumes, and design specifications.

By following these steps, you can obtain an accurate and comprehensive quote for your LOGO application, ensuring it aligns with your brand’s needs and budget.

6 Information You Need for an Accurate LOGO Application Quote

When requesting a quote, it’s important to provide detailed information to ensure accuracy. Here’s what you should be ready to provide:

Quotation Accuracy

The more detailed the information, the more accurate the quote will be. Make sure to include:

Information | Details Required |

LOGO Design | Provide a LOGO design file in PDF or AI format |

Material | Specify the logo solutions, which will decide the logo materails |

Production Volume | Provide exact quantities, like 300 units per order. |

Color | Use Pantone to specify the exact color. |

Surface Treatment | Indicate the desired finish, such as laser, Laser with oil, 3D hot stamping,Screen Printing,Metal Logo, and so on. |

LOGO Design | Material | Production Volume | Color | Surface Treatment |

AI/PDF | Logo Solutions | 300pcs /Modle | Pantone Color Code | Laser or others |

Sample Provided | Stainless Steel | Units Per Year | RAL Color Code | Laser or Others |

Why Are Some LOGO Processes More Expensive Than Others?

The cost of applying a LOGO to eyewear varies due to several factors, including the complexity of the process, the materials used, and the level of detail required. Here’s a breakdown of why some LOGO processes are more expensive than others:

Factors That Influence LOGO Application Costs

Factors | Description | Percentage Share |

Material Costs | High-quality materials like metal or gemstones are more expensive than basic plastics. | 20% |

Design and Development | Creating intricate LOGO designs requires skilled labor and advanced technology. | 15% |

Application Process | Processes like gemstone inlay or metal engraving are more labor-intensive and time-consuming. | 20% |

Labor Costs | Skilled workers are required for detailed processes, driving up costs. | 10% |

Testing and Validation | Ensuring the LOGO meets quality standards involves additional testing, which can increase costs. | 10% |

Complexity | More complex LOGOs with multiple colors or materials take longer to produce, increasing costs. | 15% |

Lead Time | Rush orders or tight deadlines may require expedited production, adding to the cost. | 5% |

Quality Contr | High-quality LOGOs require thorough quality checks, adding to the overall cost. | 5% |

| LOGO Process | Key Cost Factors | Applicable Materials | Advantages | Disadvantages | Cost Percentage | Overall Cost Assessment |

|---|---|---|---|---|---|---|

| Laser Engraving | High equipment cost, suitable for various materials, fast processing speed, design complexity affects cost | Metal, plastic, wood | High precision, durable, suitable for various materials | High initial equipment investment | Equipment investment 40%, Material compatibility 20%, Processing speed 20%, Design complexity 20% | Low to Medium |

| Mechanical Engraving | High equipment and labor costs, suitable for metal, low production efficiency | Metal | Traditional craftsmanship, tactile feel, suitable for high-end products | High cost, not suitable for mass production | Equipment investment 30%, Labor cost 40%, Material limitation 10%, Production efficiency 20% | High |

| Screen Printing | Low stencil cost, suitable for various materials, fast production speed | Plastic, metal | Cost-effective, suitable for mass production, vibrant colors | Complex designs increase time and cost | Stencil production 30%, Material cost 20%, Processing speed 30%, Design complexity 20% | Low to Medium |

| Heat Transfer Printing | High film production and equipment costs, suitable for complex patterns and multi-color designs | Plastic, metal | Ideal for complex designs, multi-color LOGOs, durable | High initial investment and film cost | Film production 35%, Equipment investment 25%, Material compatibility 20%, Design complexity 20% | Medium to High |

| Electroplated LOGO | High-quality metal materials, complex electroplating process | Metal | Enhanced visual appeal, high durability, improved brand recognition | High cost, complex process | Material cost 40%, Process complexity 30%, Environmental requirements 15%, Quality control 15% | High |

| Metal Inlay LOGO | High material and process costs, suitable for high-end designs | Metal, plastic | Luxurious feel, ideal for high-end and luxury brand designs | High production cost, complex process | Material cost 35%, Process complexity 40%, Design requirements 25% | High |

| Hand-Painted LOGO | High labor cost, high material cost, strong uniqueness | Any material | Unique, artistic, suitable for limited editions | High cost, not suitable for mass production | Labor cost 50%, Material cost 30%, Uniqueness 20% | High |

| Automated Spray LOGO | High equipment cost, high production efficiency, suitable for mass production | Plastic, metal | High efficiency, consistency, suitable for mass production | High initial investment, design complexity affects cost | Equipment investment 35%, Processing speed 40%, Quality control 25% | Medium |

| UV Printing | High equipment cost, suitable for various materials, fast processing speed | Metal, plastic, wood | Ideal for complex designs, accurate color, suitable for various materials | High initial investment | Equipment cost 35%, Material compatibility 30%, Processing speed 35% | Medium to High |

This table summarizes the key cost factors, applicable materials, advantages, disadvantages, and specific cost percentages for each LOGO process, providing a clear overview of the cost structure for making informed decisions.

Finding Ways to Reduce Costs

To manage costs effectively, consider simplifying the LOGO design, choosing cost-effective materials, and planning production schedules well in advance to avoid rush fees.

Conclusion

Branding your eyewear with a private label LOGO is a powerful way to establish your brand in the market. However, it’s essential to understand the various factors that influence the cost of LOGO application and to choose a process that aligns with your budget, materials, and branding goals. By providing detailed information to your supplier and carefully reviewing quotes, you can ensure that your LOGO not only looks great but also adds value to your products.

Whether you opt for a simple screen-printed LOGO or a luxurious gemstone inlay, the right choice will help your brand stand out in a competitive market, making your eyewear instantly recognizable to your customers.

Starting a private label eyewear business can be an exciting and lucrative venture, especially in today’s booming eyewear market. Whether you’re considering creating custom designs or leveraging existing stock frames with your logo, private labeling offers a flexible and cost-effective way to build a brand. However, the path to success involves navigating a series of critical decisions, from selecting the right manufacturer to ensuring legal compliance. This guide will walk you through the essential steps of launching your private label eyewear business, covering everything from design to marketing strategies.

What Is Private Label Eyewear and Why Consider It?

Private label eyewear involves either creating a custom line of eyewear products under your brand or purchasing pre-designed frames and adding your logo to them. This business model allows you to enter the market with a unique product offering without the need to invest heavily in design or manufacturing infrastructure.

Key Benefits and Potential Challenges of Private Label Eyewear

Benefits | Challenges |

|---|---|

Cost Efficiency: Lower production costs. | Quality Control: Ensuring consistent product quality. |

Brand Control: Maintain a unique brand identity. | Supply Chain Management: Managing third-party partners. |

Quick Market Entry: Faster launch using stock frames. | Brand Differentiation: Standing out in a crowded market. |

Choosing the Right Manufacturer for Private Label Eyewear

The success of your private label eyewear business largely depends on your choice of manufacturer. Whether you’re looking for a partner to produce custom designs or supply high-quality stock frames for branding, selecting a reliable manufacturer is crucial.

Factors to Consider When Choosing a Manufacturer

Criteria | Description |

|---|---|

Production Capacity | Can the manufacturer meet your demand and scale with your business? Check for minimum order quantities (MOQs) and lead times. |

Quality Standards | Verify the manufacturer’s track record with quality through samples, certifications, and possibly factory visits. |

Reputation | Research industry reviews and testimonials to gauge reliability and trustworthiness. |

Customization Options | Ensure the manufacturer can offer logo placement, packaging, and other customization needs, especially if using stock frames. |

Logistics and Location | Consider the location for shipping efficiency and cost. A nearby location to your market can reduce lead times and logistics expenses. |

Designing Your Private Label Eyewear Collection

Design plays a critical role in defining your brand’s identity. Whether you’re creating custom designs or selecting stock frames to brand, the choices you make in design will influence how your products are perceived in the market.

Key Steps in Designing Your Eyewear Collection

Trend Research: Monitor fashion trends, shows, and social media to ensure your designs resonate with current market preferences.

Customer Preferences: Tailor your designs to fit your target market’s tastes, whether they lean towards classic or trendy styles.

Unique Features: Incorporate distinctive elements, such as unique materials or color combinations, to set your brand apart.

Prototyping: Develop prototypes to refine your designs and ensure they meet your quality and aesthetic standards.

Material Selection for Private Label Eyewear: What Works Best

The materials used in your eyewear frames and lenses will have a significant impact on the product’s quality, durability, and aesthetics. Whether you’re selecting materials for custom designs or choosing stock frames, it’s essential to understand the properties of different materials.

Comparison of Common Materials for Eyewear Frames

Material | Properties | Common Uses |

|---|---|---|

Acetate | Durable, flexible, wide color range, hypoallergenic | High-end eyewear, custom and stock frames |

Metal | Strong, sleek, lightweight (titanium), corrosion-resistant | Premium eyewear, sports eyewear |

Plastic | Lightweight, affordable | Budget-friendly eyewear, children’s frames |

Wood and Bamboo | Unique aesthetic, eco-friendly | Niche markets, eco-conscious brands |

Lens Material Options

Lens Material | Advantages | Best For |

|---|---|---|

CR-39 | Good optical clarity, lightweight | Prescription lenses |

Polycarbonate | Impact-resistant, durable | Sports eyewear, children’s frames |

Trivex | High optical clarity, impact-resistant | High-performance lenses |

High-Index Plastic | Thinner and lighter than standard plastic lenses | Strong prescriptions, lightweight eyewear |

Customizing Eyewear Frames: Colors, Shapes, and Finishes

Customization allows you to differentiate your products in a crowded market. Whether you’re designing from scratch or branding stock frames, offering a variety of customization options can help you meet diverse customer preferences.

Customization Options

Customization Type | Description |

|---|---|

Colors | Develop custom colors that align with your brand’s aesthetic, offering a mix of classic and trendy options to attract a wider audience. |

Shapes | Offer a range of shapes, including round, square, aviator, and cat-eye, to cater to different style preferences and face shapes. |

Textures and Finishes | Add unique textures and finishes such as matte, glossy, brushed metal, or wood grain to enhance the visual and tactile appeal of your eyewear frames. |

Lens Options for Private Label Eyewear: UV Protection, Polarization, and More

Lenses are a key component of any eyewear product, affecting both its functionality and appeal. Offering a variety of lens options can enhance the value of your products and meet the diverse needs of your customers.

Types of Lens Options

Lens Type | Benefits | Ideal For |

|---|---|---|

UV Protection | Protects eyes from harmful ultraviolet rays | Sunglasses, outdoor eyewear |

Polarized Lenses | Reduces glare from reflective surfaces | Outdoor activities, driving |

Photochromic Lenses | Automatically darken in sunlight | Transitioning between indoor and outdoor settings |

Blue Light Blocking Lenses | Reduces eye strain from screens, improves sleep | Computer use, digital device users |

Mirrored Lenses | Reflects light, reduces glare, stylish appearance | Fashion-forward sunglasses, outdoor eyewear |

Anti-Reflective Coatings | Reduces reflections, improves clarity | Night driving, prescription eyewear |

Branding and Packaging: Making Your Private Label Stand Out

Effective branding and packaging are critical for creating a memorable and attractive product that resonates with customers. Your brand identity should be reflected in every aspect of your product, from the logo on the frames to the packaging design.

Key Aspects of Branding and Packaging

Aspect | Description |

|---|---|

Logo Placement | Choose subtle yet visible locations such as the temple, inside the temple arms, or on the lens for logo placement. |

Brand Story | Develop a compelling narrative that communicates your brand’s mission, values, and unique selling points. |

Packaging Design | Use high-quality materials and design elements that reflect your brand’s identity, enhancing the unboxing experience. |

Offering Stock Eyewear with Logo Customization

In addition to custom-designed eyewear, offering stock frames with your logo can be an efficient way to expand your product line. This approach allows you to quickly enter the market with a diverse range of products while maintaining brand consistency.

Benefits of Stock Eyewear with Logo Customization

Benefit | Description |

|---|---|

Faster Time to Market | Utilize pre-designed frames to reduce production time and quickly launch your branded product line. |

Lower Costs | Save on design and prototyping costs by using existing frames, making it more accessible for new brands. |

Product Variety | Offer a range of styles under your brand, catering to different customer preferences with stock frames. |

Scalability | Easily reorder popular styles to meet demand without long lead times. |

Navigating Quality Control in Private Label Eyewear Production

Maintaining consistent quality across your product line is essential for building a trusted brand. Quality control should be integrated into every stage of the production process, whether you’re working with custom designs or stock frames.

Quality Control Best Practices

Stage | Quality Control Practice |

|---|---|

Material Inspection | Ensure raw materials meet quality standards by checking for defects before they enter production. |

In-Process Inspections | Conduct regular checks during production to catch and correct issues early, such as frame accuracy. |

Final Product Testing | Perform thorough testing, including drop and stress tests, before packaging and shipping products. |

Third-Party Audits | Consider using independent inspectors to audit the manufacturing process and ensure consistent quality. |

Legal Aspects of Private Labeling: Trademarks and Compliance

Understanding the legal landscape of private labeling is crucial to protecting your brand and avoiding potential legal pitfalls. This involves securing trademarks, ensuring compliance with industry regulations, and protecting your intellectual property.

Legal Considerations

Aspect | Description |

|---|---|

Trademark Protection | Register your brand’s name, logo, and designs as trademarks to protect against intellectual property theft. |

Compliance | Ensure your products meet safety and regulatory standards in all markets you plan to operate in. |

Contractual Agreements | Establish clear contracts with manufacturers, covering confidentiality, quality expectations, and timelines. |

Marketing Strategies for Launching a Private Label Eyewear Line

Marketing is a critical component of launching your private label eyewear business. An effective marketing strategy will help you reach your target audience, build brand awareness, and drive sales.

Marketing Tactics

Tactic | Description |

|---|---|

Online Presence | Build a strong online presence through a professional website and active social media engagement. |

Influencer Partnerships | Collaborate with influencers who align with your brand to reach a broader audience. |

Content Marketing | Create educational and inspirational content, such as blogs, videos, and style guides, to engage customers. |

Email Marketing | Use personalized email campaigns to keep customers informed about new products and promotions. |

Trade Shows and Events | Participate in industry events to showcase your products and network with potential buyers and partners. |

Conclusion

Starting a private label eyewear business offers numerous opportunities to build a successful brand, whether through custom designs or branding existing stock frames. By focusing on quality, customization, and effective marketing, you can create a product line that resonates with your target audience and stands out in a competitive market. With the insights provided in this guide, you’re well-equipped to take the first steps toward launching your own private label eyewear brand.

HAVE A LOOK AT OUR KNOWLADGE CENTER

We have found that many people would like to learn about the full and professional knowledge of eyewear industry, but do not have suitable materials to read. Our team of engineers constantly exports technology on our download page and blog, which you can download for free. In the meantime, if you have a better idea or a case you would like to share, feel free to send it to us. We will contact you as soon as possible and update information or case studies on the website.

In a Mass-Produced World, Handmade Still Stands Apart When it comes to eyewear, there’s something undeniably…

Introduction: Beautiful Materials Alone Aren’t Enough You’ve probably heard the phrase tossed around: “We use Mazzucchelli…

Let’s Be Honest: It’s the Finish That Makes You Fall in Love If you’ve ever picked…

Introduction: Craftsmanship in Every Curve In a world where speed and automation dominate production, handmade acetate…

Denmark is widely recognized for its clean lines, minimalism, and mastery of balance. From architecture and…

Introduction: Confidence Begins with Understanding Your Features Let’s get one thing clear from the start: your…

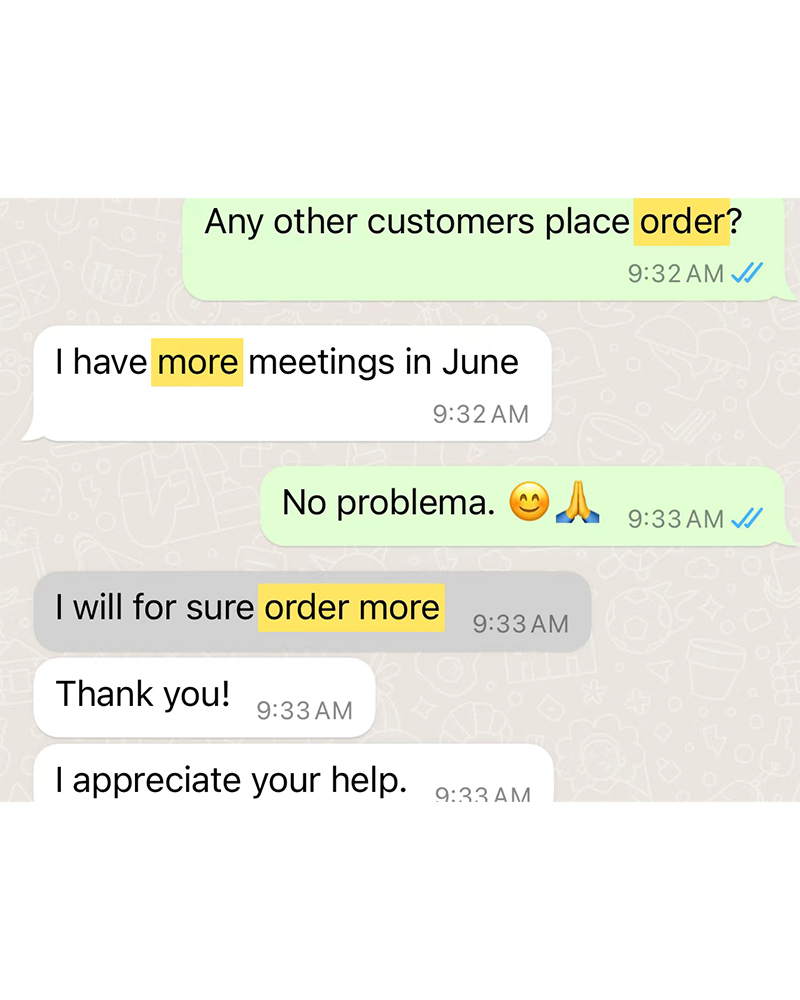

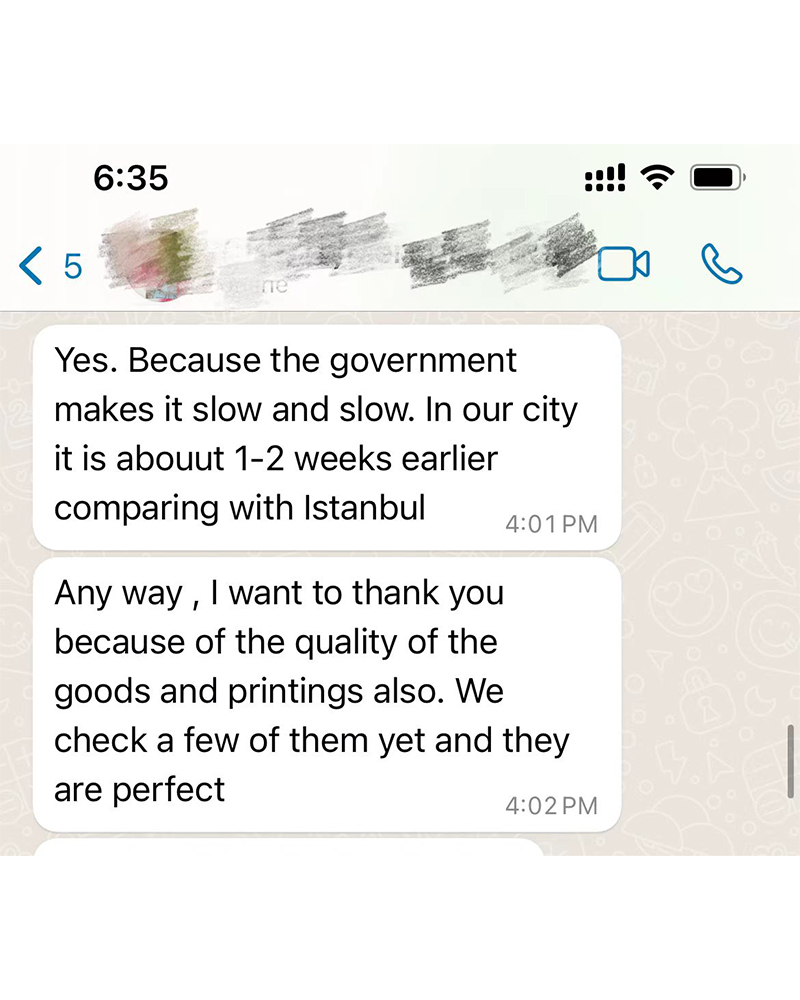

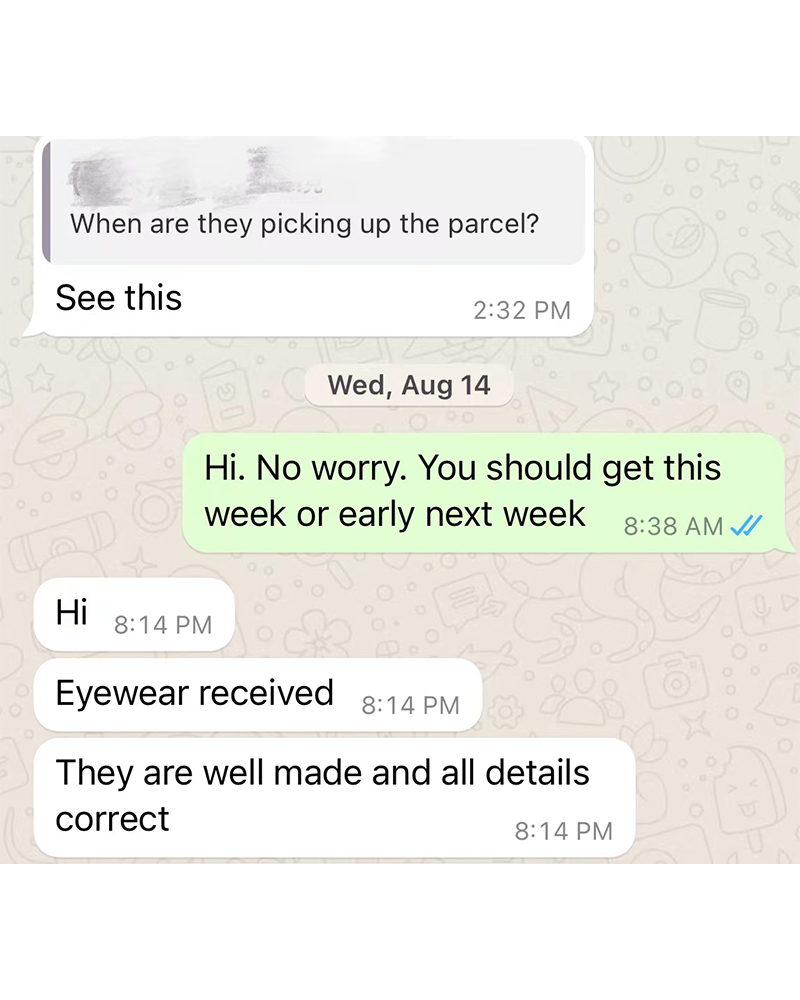

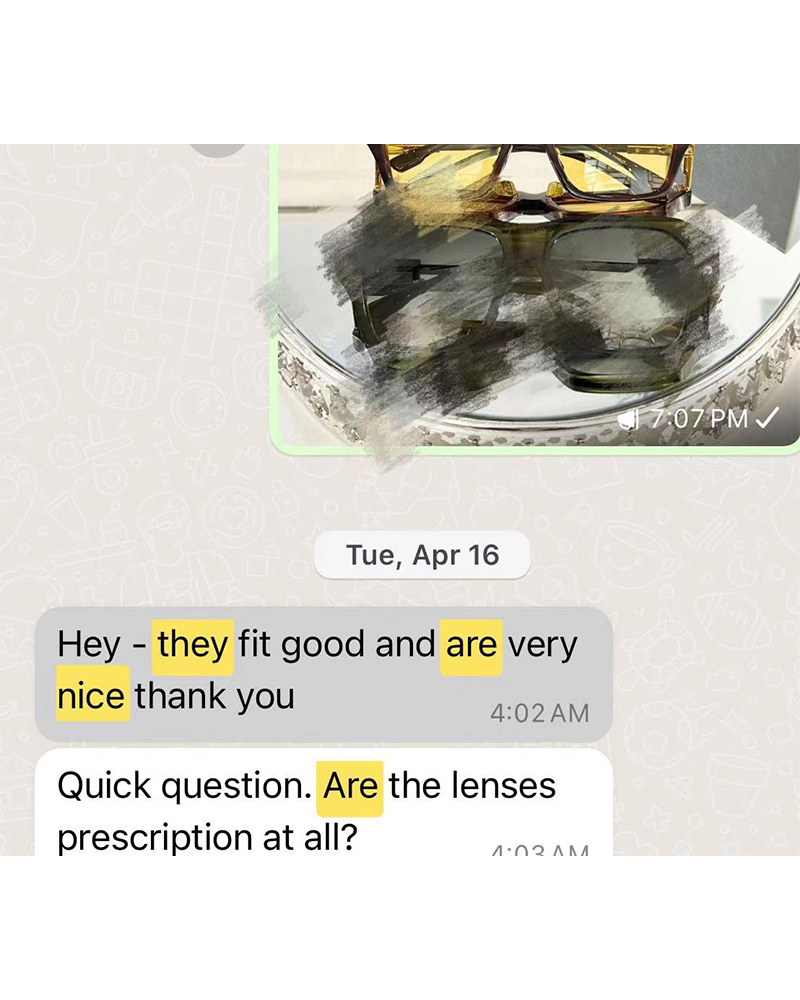

Here are reviews from various countries and perspectives, featuring feedback from eyewear wholesalers, eyewear store owners, and custom eyewear brands. We are grateful for our customers’ reviews. Your positive feedback motivates us to continue striving for excellence. We are committed to earning your trust and exceeding your expectations at every step of the way.

These are the most frequently asked questions. If you cannot find an answer here, please contact us via email at eyewearbeyondofficial@gmail.com

Answer: For our regular series, the MOQ is 10 pieces per color. For our high-end series, you can mix different models as long as the total order reaches 35 pieces.

Answer:

Yes, we offer a variety of logo customization options, including:

Answer: Our eyewear stocks include acetate, metal, and TR90 , wooden , buffalo horn ,as well as Italy Acetate for frames, and polycarbonate, CR39, and high-index lenses, ensuring durability and style.

Answer: It Depends on orders details as quantity ,stock info, normlly 3-7 days to ship. if do logoes or in high season will take longer.

Answer: Our eyewear products are manufactured to meet rigorous international standards, ensuring safety and quality. We hold several certifications, including CE certification for the European market, FDA certification for the United States, and ISO certifications for quality management systems. These certifications validate our commitment to producing high-quality eyewear that complies with global safety and performance standards.

Answer: Yes, We offer competitive wholesale discounts for bulk orders. Our discount structure is designed to provide better pricing as the order quantity increases. The exact discount rates depend on the volume of your order and the specific customization options you choose. We aim to support our clients with cost-effective solutions without compromising on quality. For detailed information on our wholesale pricing and to discuss your specific needs, please contact our sales team directly. We are committed to offering the best value to our wholesale partners.

Answer:Yes, we provide samples to help you evaluate the quality of our products before committing to a bulk order. Please note that sample fees may apply.

Answer: Yes, most of the styles we offer as samples will remain in stock. If any styles are discontinued, we will notify you in advance and provide similar alternatives. we will restock most of our eyewear modles

Answer:We regularly update our inventory with new styles every month. Stay connected with us to receive updates on the latest trends and fresh designs.

Before we begin crafting your wholesale eyewear collection, we need specific details about your order requirements. Please complete the form below with your design preferences and quantities. We’ll promptly review your submission and provide a quote along with the next steps to get your order started.

Follow Us:

Set your brand apart with custom-designed eyewear! At Eyewearbeyond, we specialize in tailor-made eyeglasses and sunglasses that fit your specifications. Request a quote and start designing now!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Ready to bring your unique eyewear designs to life? Start your journey to custom eyewear today—request your free quote now!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Looking for the perfect custom eyewear to represent your brand?

Our experts can help you find the perfect eyewear solution tailored to your requirements!

You have successfully subscribed to the newsletter

There was an error while trying to send your request. Please try again.