How to Design a Unique Eyewear Logo?

Standing out in the eyewear industry, where competition is fierce, can be quite a challenge. Many…

Explore our variety of premium eyewear logo branding options custom process. Discover successful private lable solution to make your eyewear brand unique.

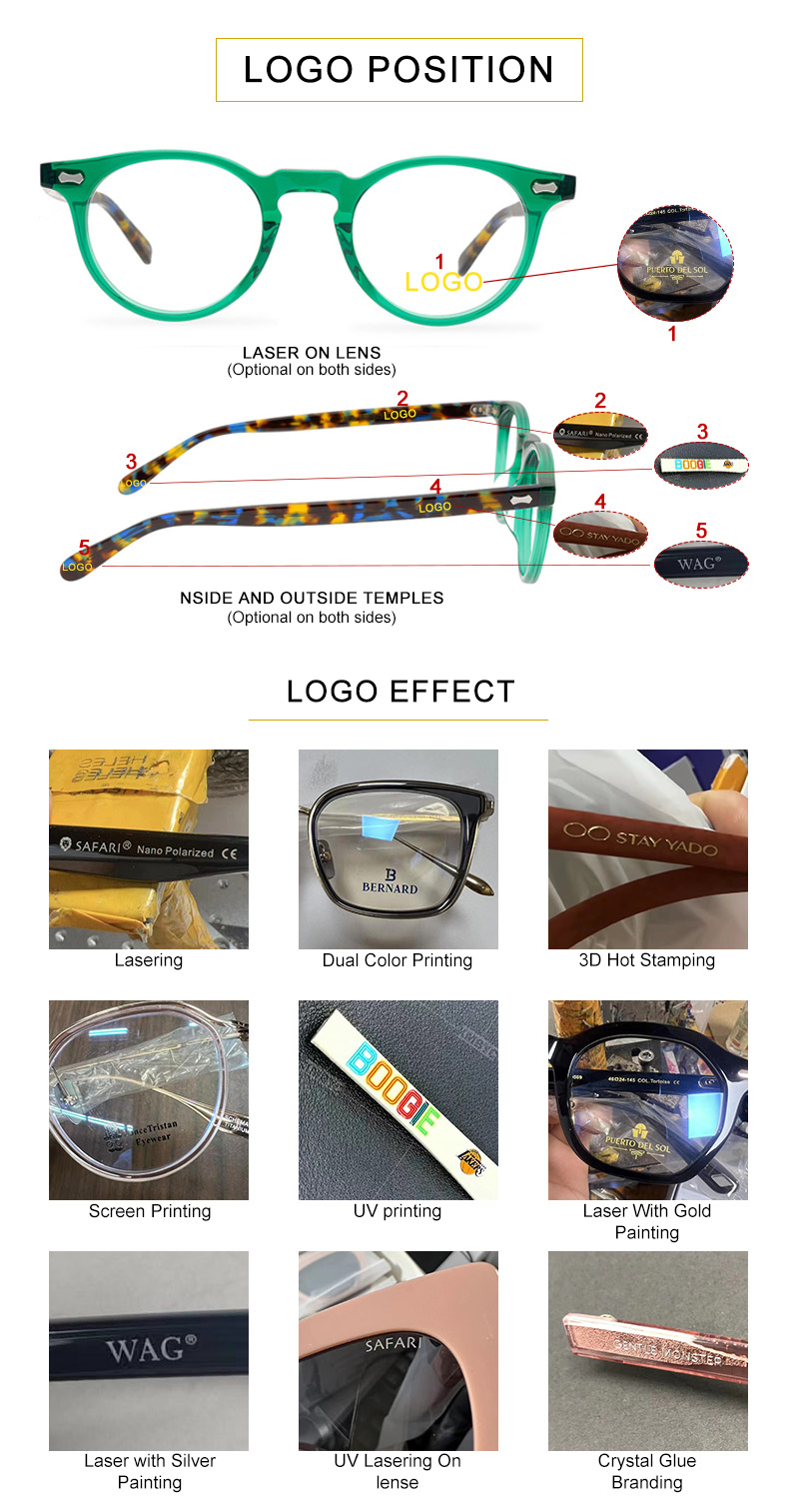

Private Label Eyewear – Amplify Your Brand with Superior Logo Customization. Our private label eyewear collection offers an extensive range of over 10 high-quality logo customization options, from sleek laser engraving to bold metal inlays and vibrant UV printing. These premium logo applications not only enhance the visual appeal of your eyewear but also strengthen your brand’s presence in the market. Perfect for eyewear brands, wholesalers, and independent labels, our customizable logos ensure that your brand stands out, drives recognition, and leaves a lasting impression on your customers.

Remove the surface color to see the base color

Application: (single or double color)metal and plastic temple outside/sunlenses

High power laser to engrave logo and can print with color

Application: mainly in metal

Gold or silver color. Logo protrude and not in the same surface with temple surface

Application: injection and acetate frames

Logo already in the mold.

Application: injection and metal frames

Engrave a groove and lay in the metal doco

Application: injection/wood/acetate frames

Application: injection/metal/acetate frames

Logo in the same surface with temple. Gold/Silver

Application: acetate frames

Application: acetate frames

Engrave a groove, lay in the small logo metal piece, then cover with epoxy glue. Polishing after drying.

Application: acetate frame

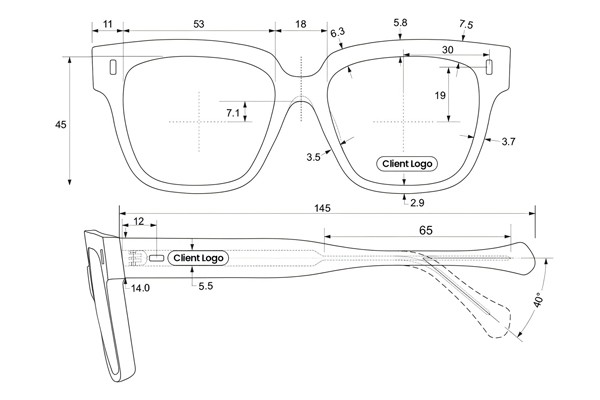

Our eyewear logo customization service allows you to place your brand’s logo on any part of the glasses, ensuring maximum visibility and impact. From the temples and nose bridge to the inner arms and lens corners, we offer precise application methods like laser engraving, metal inlays, and UV printing. Each logo is meticulously crafted and positioned to perfectly reflect your brand’s identity, making every pair of eyewear a true representation of your unique style.

Surface Lasering: Precision in Branding

Surface lasering is a meticulous process where the top layer of material on the eyewear is carefully removed to reveal the base color beneath. This technique creates a sharp contrast between the surface and the underlying layer, resulting in a distinctive and durable logo or design.

Application:

This method ensures that your logo is not only eye-catching but also resistant to wear and fading, making it a long-lasting branding solution.

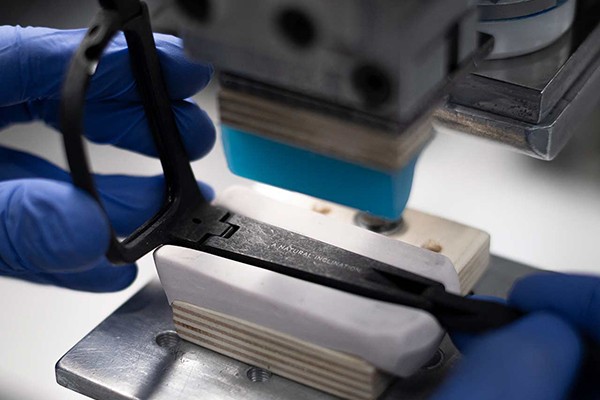

Deep Lasering: Engrave with Depth and Color

Deep lasering is a high-precision process that uses powerful lasers to engrave logos deeply into the material, creating a permanent and tactile design. Unlike surface lasering, deep lasering penetrates the material, allowing for a more pronounced and durable mark. After engraving, the recessed area can be filled with color, enhancing the logo’s visibility and aesthetic appeal.

Application:

Deep lasering ensures that your logo is not only visually striking but also highly resistant to wear and corrosion, making it an excellent choice for premium eyewear branding.

3D hot stamping is a premium branding technique where your logo is embossed onto the surface of the eyewear, creating a raised, three-dimensional effect. This method combines heat and pressure to permanently stamp the logo onto the material, resulting in a design that is both durable and visually striking. The added depth gives the logo a tactile quality, enhancing the luxury feel of the eyewear.

Application:

The 3D hot stamping technique is perfect for high-end brands looking to create a luxurious and durable logo that stands out on their eyewear, offering a distinctive touch of sophistication that customers can see and feel.

Integrated Metal Logo: Seamless and Durable Branding

The integrated metal logo is a process where the logo is embedded directly into the mold during the manufacturing of eyewear frames. This ensures that the logo is an inherent part of the frame, offering a sleek, seamless look with exceptional durability. The logo becomes a permanent fixture of the eyewear, standing out with a polished metal finish that enhances the frame’s overall design.

Application:

This method is ideal for brands seeking a durable and refined logo that is seamlessly integrated into the design of their eyewear, offering a premium and long-lasting branding solution.

Grooved Engraving with Inlaid Metal Logo: Precision and Luxury

This technique involves engraving a precise groove into the surface of the eyewear frame and then inlaying a metal logo into the groove. The result is a sleek, flush design where the metal logo sits perfectly within the frame, offering a sophisticated and durable branding element. This method combines the precision of engraving with the elegance of a metal inlay, creating a logo that is both visually striking and tactile.

Application:

This method is ideal for brands looking to create a luxurious, detailed logo that is securely embedded in the frame, ensuring longevity and a refined appearance that resonates with quality and elegance.

Screen Printing: Vibrant and Versatile Logo Application

Screen printing is a versatile technique that applies logos and designs onto eyewear frames with precision and vivid color. This process involves creating a stencil (or screen) and using it to layer ink onto the frame’s surface. The result is a sharp, high-contrast logo that is both durable and visually appealing.

Application:

Screen printing is perfect for brands seeking a cost-effective and flexible method to add detailed logos to their eyewear, ensuring a bright, durable finish that maintains its quality over time.

UV Sticker Logo: Sleek and Shiny Surface Branding

The UV sticker logo method applies a glossy gold or silver sticker directly onto the surface of acetate frames, creating a sophisticated and high-end branding effect. Utilizing UV curing technology, the sticker adheres seamlessly to the temple surface, ensuring a smooth, flush finish that enhances the frame’s aesthetic without disrupting its sleek design.

Application:

This technique is ideal for brands seeking an elegant and durable logo solution that enhances the appeal of acetate frames with a polished and professional finish.

Cutting/Engraving Logo with Premium Colors: Precision and Luxury

Cutting/engraving with premium colors is a refined process that involves engraving your logo onto acetate, plastic, or TR90 materials, followed by the application of luxurious color fills like gold, silver, or white. This technique not only creates a detailed and permanent design but also adds an element of sophistication and elegance to your eyewear.

Application:

This method is perfect for high-end eyewear brands looking to make a lasting impression with a logo that is not only visually stunning but also exudes a premium feel, enhancing the brand’s identity.

Metal Foil Sticker: Embedded Elegance with a Polished Finish

The metal foil sticker technique is a meticulous process where a groove is engraved into the acetate frame, and a small metal logo piece is carefully inlaid into this groove. The logo is then sealed with a layer of clear epoxy glue, ensuring it is securely embedded. After the epoxy dries, the surface is polished, resulting in a smooth, glossy finish that highlights the logo’s metallic shine.

Application:

This technique is perfect for brands looking to create a refined, luxurious logo on acetate frames, combining the elegance of metal with the durability and gloss of epoxy for a premium branding solution.

By choosing Eyewearbeyond, you not only receive top-tier product quality but also benefit from our extensive experience in customizing logos for a diverse range of clients worldwide. With a broad customer base spanning across different continents, we understand the unique branding needs of various markets. Our expert team uses state-of-the-art laser engraving and UV printing technology to apply your logo with precision, ensuring it stands out on each pair of glasses. Leveraging our experience and advanced techniques, we guarantee that your customized logo is durable, vibrant, and perfectly aligned with your brand’s identity.

Imagine your logo, expertly crafted and shining on every pair of glasses, capturing attention and leaving a lasting impression.

With over 200 successful brand collaborations in 50 countries, we understand what it takes to create eyewear that resonates globally.

Our cutting-edge facilities, equipped with 10 advanced laser engraving and UV printing machines, ensure your logo is applied with unmatched precision every time.

Choose from over 500 eyewear styles and customize them with 100+ options to perfectly reflect your brand’s identity.

Need help with your logo? Our design team offers 20+ logo templates and custom design support to bring your vision to life.

We value your time—expect your custom logo eyewear to be delivered in just 2 weeks, even for orders exceeding 1,000 pairs.

Save 30% more than the industry average without compromising on the quality and impact of your eyewear.

With 10+ years of expertise, our team is dedicated to ensuring your brand stands out and leaves a lasting impression.

Whether you’re a startup or an established brand, we’re ready to help you create unforgettable, custom-branded eyewear that elevates your business.

Overview of how the entire process works In this section. The custom eyewear manufacturing process involves several key steps, each crucial to ensuring both the quality and uniqueness of the final product.

The realm of eyewear has witnessed a revolutionary shift, thanks in part to the advancements in glasses printing technologies. Today, the spectacles we wear are not just vision aids but a statement of personal style, made possible through various printing technologies. This section delves into the evolution and role of these technologies in modern eyewear.

You can freely choose logos such as patterns, text, symbols, etc.

Is there a limit to the size of the logo?

We will not limit the size of your logo. But you need to send us the pattern of your logo and the required size. We need to make sure that the logo can be made in the right place.

In eyewear design, there are several strategic spots where a logo can be placed to enhance brand visibility and recognition. Here are some common options:

Temples (Arms): This is the most popular location for placing a logo. It’s visible when the eyewear is worn and also when it’s placed on a table or hung from a shirt. Logos can be engraved, printed, or embossed here.

Lens: Branding on the lens is typically subtle, such as a small logo etched at one corner. This placement is discreet yet visible up close, offering a premium look.

Nose Pads: Logos on nose pads are an understated choice, usually visible only during close inspections or when the eyewear is not being worn. It’s a detail that adds a touch of luxury and exclusivity.

Temple Tips: Some brands choose to include their logo on the inside or outside of the temple tips. This is less visible during wear but can be a detail that catches the eye when the eyewear is removed or being adjusted.

Front Frame: Placing a logo on the upper corner or the center of the front frame is another option. It’s more prominent and often used in statement pieces.

End Pieces: The small section that connects the lenses to the arms can also feature small logos. This is a subtle placement but adds a professional touch.

Each location offers different visibility and contributes to the eyewear’s overall aesthetic. The choice depends on how prominently you want the brand featured and the design of the eyewear itself.

3.1 Laser

After adjusting the position of the temples, start the laser engraving machine. Create the corresponding logo by burning the surface of the material.

This method is relatively cheap and has a short production time. But the color is relatively single, so you can’t make too complex logos (very small and dense patterns)

3.2 Laser spot paint

On the basis of the laser method, we also added a coloring process.

In this way, we can make a single logo color into Pantone color. But because the basis of this method is a laser. Therefore, it also cannot avoid the disadvantage of not being able to make an overly complex logo.

3.3 screen Printing

First, make a printed version of the logo. Then infiltrate the prepared ink into the screen printing plate to obtain the corresponding logo mark.

The logo color is very rich. Preparatory work such as the screen template and ink preparation takes a long time.

3.4 UP Metal Tag

Compared with other logo-making methods, metal labels are the most expensive.

The reason is that this method has strict production technology, high selection standards, and long mold design time.

At the same time, for these reasons, the metal logo has a distinct three-dimensional effect. At the same time, the logo has a very bright luster, and abrasion resistance is also very good.

3.5 Crystal glue

This is a colloidal logo with a flat structure. It can have a variety of colors. And it has relatively good wear resistance, this kind of logo can usually be used for 2-3 years. But the impact resistance of this logo is not very good. (Normal use, touching, or dropping the glasses will not affect it)

3.6 Hot Stamping

Hot stamping, a distinct method in the world of eyewear printing, brings its unique charm and functionality.

3.7 Metal Logo

Metal logos represent a sophisticated aspect of eyewear branding, offering a distinct and luxurious touch. This section delves into the methods of crafting and affixing metal logos and their implications for eyewear design.

| Description | Applicable Materials | Advantages | Common Applications |

Silk Screen Printing | Uses a mesh stencil to apply ink to the surface of materials, allowing for multi-color designs | Plastic, metal, wood, lenses, etc. | Vibrant colors, suitable for mass production, clear patterns | Custom patterns, brand logos, decorative designs |

Hot Stamping | Uses heated molds to press metallic foil or plastic film onto the material surface for a glossy effect | Plastic, metal, leather, etc. | High-end visual effect, strong durability, suitable for premium branding | High-end eyewear logos, decorative designs, special pattern treatments |

Laser Engraving | Uses lasers to precisely engrave patterns or text on various materials, often for high-precision customization | Metal, wood, plastic, lenses, etc. | High precision, long-lasting, wear-resistant | High-end brand logos, personalized customization, intricate patterns |

Metal Logo Implementation | Embeds metal logos into the eyewear frame or temples, enhancing brand recognition and premium feel | Plastic, metal, wood | Strong premium feel, enhances brand value, outstanding visual effect | High-end brand eyewear, special edition products |

UV Patch | Uses UV printing technology to apply multi-color patterns to eyewear surfaces, suitable for complex designs and gradients | Plastic, metal, wood | Multi-color printing, fine patterns, suitable for complex designs | Custom patterns, brand logos, artistic designs |

Crystal Gel Lettering | Uses transparent crystal gel to apply three-dimensional letters or logos to the eyewear surface, enhancing visual effects | Plastic, metal, wood | Strong 3D effect, good transparency, adds texture | High-end brand logos, special custom eyewear |

3D Printing | Uses 3D printing technology to directly manufacture frames or parts, suitable for complex shapes and unique designs | Plastic, resin | High design freedom, suitable for customized production, rapid prototyping | Custom designs, prototyping, personalized eyewear |

This table helps custom eyewear and wholesale customers quickly understand the characteristics and application scenarios of various printing and marking technologies, enabling better choices for product customization and branding.

From silk screen printing that offers a rich color palette to laser engraving for precise detailing, each technology has its unique advantages and applications. As we explore these technologies further, it becomes evident how they have transformed eyewear into a canvas for artistic expression and personal branding.

Silk Screen Printing stands as one of the most prevalent and versatile methods for eyewear decoration. This section provides an overview of the process, along with its unique advantages and limitations, illustrating why it remains a popular choice in the eyewear industry.

Process Overview

The process of silk screen printing on eyewear frames begins with the creation of a stencil or a screen, which is essentially a fine mesh stretched over a frame. The desired design or text is imprinted on this mesh. During the printing process, ink is pushed through the stencil onto the surface of the eyewear frame. This technique allows for the application of intricate designs and texts on various parts of the frame, including areas that are not entirely flat, like curved or slightly uneven surfaces.

The process typically involves several steps, starting with the preparation of the screen, followed by the application of the ink, and then the drying or curing of the ink to ensure durability. It’s a method that requires precision and skill, as the alignment of the screen and the amount of ink applied can significantly affect the quality of the final product.

Advantages and Limitations

One of the key advantages of silk screen printing is its versatility in color. It can produce vibrant, opaque colors that are perfect for branding and making a bold statement. The technique allows for the application of very small text and detailed designs, which is crucial for branding and customization purposes. Additionally, due to the flexibility of the rubber squeegee used in the process, silk screen printing is effective on slightly irregular surfaces, a common characteristic in eyewear frames.

However, there are some limitations to this technique. One major drawback is the adherence of the ink. In some cases, the printed design may have average adhesion, necessitating the use of hardening agents to improve durability. Moreover, the process is more labor-intensive compared to other printing methods, which can be a consideration in terms of production time and cost.

Despite these limitations, silk screen printing remains a popular choice due to its ability to produce rich colors and intricate designs, adding significant aesthetic value to eyewear products.

Hot stamping, a distinct method in the world of eyewear printing, brings its unique charm and functionality.

Technique and Applications

Hot stamping in eyewear involves the application of foil or pre-dried ink to the frame using high temperatures and pressure. The process begins with the creation of a stamp or die, often made of metal, which is engraved with the desired design. This die is then heated and pressed against a foil or ink layer placed on the eyewear frame. The heat and pressure transfer the design from the foil to the frame, leaving a crisp, clean imprint.

This technique is particularly popular with acetate, TR90, and injection-molded eyewear frames, where the smooth surface is ideal for the transfer of the foil or ink. Hot stamping is often used for adding brand logos, decorative patterns, or textual information like model numbers and sizes on the inside of the frame or on the temples. The resultant print has a unique metallic sheen, lending a premium look to the eyewear.

Advantages and Limitations

One of the main advantages of hot stamping is the luxurious finish it provides. The metallic sheen of the foil adds an element of sophistication and high-end appeal to eyewear. The technique also allows for a certain degree of textural contrast, as the stamped design can be slightly raised or recessed, depending on the type of die used.

However, hot stamping does have its limitations. The color palette is relatively limited, typically confined to metallic hues like gold, silver, and gunmetal. Additionally, the size of the text or design is constrained; overly small or intricate details may not transfer effectively. The technique is also best suited for flat or gently curved surfaces, limiting its application on more complex frame shapes.

Laser engraving has emerged as a highly precise and versatile technology in the realm of eyewear customization.

Methodology Explained

Laser engraving utilizes the power of laser beams to etch designs or text onto eyewear frames. This process involves directing a concentrated beam of light onto the surface of the glasses, which precisely removes or vaporizes the material’s surface layer, leaving a permanent mark. The precision of the laser allows for intricate and detailed designs, which can be customized to a high degree.

This method is adaptable to various materials used in eyewear manufacturing, such as acetate, metal, titanium, and even more exotic materials like buffalo horn. It’s particularly favored for its precision and ability to create detailed and durable designs that are resistant to wear and fading.

Diverse Applications in Eyewear

Laser engraving in eyewear can take several forms, each suited to different design needs and aesthetic preferences. Some common forms include:

Shallow Engraving: This technique involves lightly etching the surface of the frame to create subtle designs. It’s commonly used for adding branding elements like logos, model names, or size specifications without altering the frame’s structure significantly.

Deep Engraving: For a more pronounced effect, deep laser engraving carves out a noticeable groove in the frame. This technique can be combined with color filling, where the engraved area is filled with colored ink or paint, enhancing the visibility and contrast of the design.

Metal Frame Engraving: There are specific approaches for metal frames, such as engraving post-plating, which involves engraving through a plated layer to reveal the underlying metal, creating a contrasting effect. Pre-plating engraving is also common, where the frame is engraved first and then plated, resulting in a more subtle design integration.

Laser engraving is celebrated for its precision and versatility, allowing for both subtle and bold customizations on eyewear. It offers designers and manufacturers the ability to create detailed, durable designs that can withstand the rigors of daily use without fading or wearing away.

Metal logos represent a sophisticated aspect of eyewear branding, offering a distinct and luxurious touch. This section delves into the methods of crafting and affixing metal logos and their implications for eyewear design.

Crafting and Affixing Metal Logos

Creating a metal logo for eyewear involves several intricate steps. The process typically starts with designing the logo, which is then transformed into a physical form through methods such as wire cutting, embossing, or casting. These logos can be made from various metals, including lightweight options like aluminum for comfort.

Once the metal logos are crafted, they are attached to the eyewear frames. This attachment can be achieved through different methods, such as welding, soldering, or using adhesives, depending on the material of both the logo and the frame. The logos are often placed strategically on the temples or the front of the frame, serving as a prominent branding element.

The logos might also undergo additional processes like polishing, painting, or plating to enhance their appearance and durability. This not only improves the aesthetic appeal but also protects the logo from wear and tear, ensuring it remains a lasting part of the eyewear.

Implications for Eyewear Design

The use of metal logos in eyewear design has several implications. Firstly, it adds a sense of luxury and exclusivity to the product. A well-designed metal logo can elevate the perceived value and brand prestige of a pair of glasses.

Moreover, metal logos offer a tangible texture contrast to the frame, whether it’s made of acetate, metal, or other materials. This contrast can enhance the tactile experience for the wearer and add depth to the eyewear’s design.

However, the incorporation of metal logos also presents challenges, such as ensuring the logo’s weight does not compromise the comfort and balance of the glasses. Designers must carefully consider the size, placement, and material of the logo to maintain the eyewear’s functionality and comfort.

In conclusion, metal logos are more than just a branding tool; they are a design element that can significantly impact the overall look and feel of a pair of glasses, offering a blend of aesthetics and tactile experience.

UV Patch technology is a relatively novel and innovative method in eyewear customization, offering unique aesthetics and durability. This section delves into the process of UV Patch application and its impact on eyewear design.

Process and Application

UV Patch technology involves creating thin, metallic or decorative patches that are adhered to the eyewear frames using UV-sensitive glue. The process begins with designing and manufacturing the patch, often featuring intricate designs, logos, or text. The patch is then meticulously placed on a predetermined area of the eyewear frame.

Once positioned, UV-sensitive adhesive is applied, and the patch is exposed to ultraviolet light. This exposure causes the adhesive to cure rapidly, creating a strong bond between the patch and the frame. The precision of this method allows for the placement of detailed and delicate designs on various parts of the frame, including curved or uneven surfaces.

Durability and Aesthetic Impact

One of the key advantages of UV Patch technology in eyewear is its durability. The strong bond formed by the UV-cured adhesive ensures that the patch remains securely attached, even with regular wear and exposure to various elements. This method provides a lasting decorative feature on the eyewear without the risk of peeling or fading over time.

From an aesthetic standpoint, UV patches can significantly enhance the visual appeal of eyewear. They allow for the incorporation of metallic sheens, vibrant colors, and intricate designs that might be challenging to achieve with other printing or engraving methods. This technology can transform a standard pair of glasses into a fashion statement, reflecting personal style or brand identity.

However, the application of UV patches requires precision and care, as misalignment can affect the final appearance of the product. Additionally, the design and placement of these patches need to be carefully considered to maintain the overall balance and comfort of the eyewear.

Crystal Gel Lettering is a unique and visually striking method used in eyewear customization, known for its dimensional and glossy finish. This section examines the process of applying crystal gel lettering and its impact on eyewear aesthetics.

Process and Application

The application of crystal gel lettering on eyewear involves a detailed and meticulous process. Initially, the design, which can be a text or a pattern, is carefully engraved or molded onto the eyewear frame. This engraving creates a recessed area where the crystal gel, a type of resin with a glass-like clarity, is applied.

Once the design is engraved, the crystal gel, often mixed with colorants to achieve the desired hue, is carefully filled into the recessed areas. The gel is then allowed to cure and harden, a process that can be accelerated using UV light. The result is a raised, glossy design that stands out against the frame, adding both texture and visual interest.

Aesthetic Appeal and Durability

Crystal gel lettering adds a unique aesthetic appeal to eyewear. The glossy, raised finish of the gel creates a tactile element that is both visually attractive and pleasant to touch. This technique is particularly effective for bold designs and brand logos, making them pop and catch the eye.

In terms of durability, crystal gel lettering is quite robust. Once cured, the gel is resistant to chipping and peeling, maintaining its appearance over time even with regular use. This durability makes it an excellent choice for eyewear, which often undergoes daily wear and tear.

However, there are some considerations to keep in mind. The process of applying crystal gel lettering is labor-intensive and requires precision, which can be a factor in production time and cost. Additionally, the weight and thickness of the gel need to be carefully managed to ensure that it does not affect the comfort and balance of the eyewear.

3D printing technology, when applied to creating logos and graphics on eyewear, offers a new dimension of customization. This section explores the specific application of 3D printing for adding graphical elements to eyewear, discussing its advantages and limitations.

Method and Application

In the context of eyewear, 3D printing for logos and graphics involves using a 3D printer to apply text and image designs directly onto the surface of the glasses. This method differs from traditional 3D printing of entire objects; instead, it focuses on adding detailed graphical elements to the existing eyewear frames.

The process enables the creation of bespoke, intricate designs that can be tailored to individual preferences or brand requirements. This approach to printing allows for a high level of detail and personalization in the design, making each piece unique.

Advantages and Limitations

One of the primary advantages of using 3D printing for eyewear graphics is the ability to produce highly individualized and creative designs. This method can bring to life complex patterns and detailed images that may be challenging to achieve with conventional printing techniques.

However, there are limitations to this technology. The range of colors available in 3D printing for graphics is relatively limited, often resulting in more monochromatic designs. Additionally, the adhesion of the printed material to the eyewear frame can be a concern. Over time, the printed designs may be prone to wearing off or peeling, especially under regular use or exposure to environmental factors.

Currently, the application of 3D printing for graphics on eyewear is still in a nascent stage. While it offers unique customization possibilities, its practical use is limited by the current technology’s constraints in color variety and durability.

That’s a succinct and insightful summary of the evolving technologies in eyewear customization. It beautifully captures how advances in printing and manufacturing technologies are enhancing the way eyewear is personalized, merging functionality with fashion. As these technologies mature, they indeed promise to make eyewear an even more integral part of personal style and expression. This narrative not only emphasizes the technological strides but also aligns perfectly with consumer desires for unique and expressive accessories, reinforcing the role of eyewear as a key element in personal branding and style in the fashion industry.

HAVE A LOOK AT OUR KNOWLADGE CENTER

We understand that many eyewear and sunglass brands are keen to explore the possibilities of private labeling but often lack the in-depth knowledge needed to fully leverage this opportunity. Our dedicated team frequently updates our Private Label page and blog with expert insights and detailed information on private labeling in the eyewear industry, which you can access for free. If you have an innovative idea or a case you’d like to share, feel free to reach out. We’ll connect with you promptly and update our resources with new case studies or information to support your brand’s growth.

Standing out in the eyewear industry, where competition is fierce, can be quite a challenge. Many…

When it comes to eyewear design, the placement of your logo is a crucial element. A…

When customizing a logo on eyewear, brands often face a critical question: how can they ensure…

In the process of customizing an eyewear brand, the logo serves as much more than just…

Have you ever wondered why many high-end eyeglasses on the market feature such distinctive and long-lasting…

Quick to know about OEM eyewear with Rebornvision

These are the most frequently asked questions for Private Lable On eyewear. If you cannot find an answer here, please contact us via email at rebornvision@foxmail.com

1. What is a custom logo on eyewear?

A custom logo on eyewear refers to a personalized design, emblem, or brand name that is applied to eyeglass or sunglass frames. This logo can be placed on various parts of the eyewear, such as the temples, nose bridge, or lens corners. The purpose of a custom logo is to represent a brand or company, providing a unique identity to the product. Custom logos are essential for branding, helping companies establish a recognizable presence in the market. They also allow eyewear brands to differentiate their products from competitors by adding an exclusive touch that aligns with their brand’s image and values.

2. What are the benefits of adding a custom logo to eyewear?

Adding a custom logo to eyewear offers multiple benefits:

Brand Recognition: A visible logo on eyewear helps customers easily identify and remember your brand.

Market Differentiation: A unique logo differentiates your products from competitors, making them stand out in a crowded market.

Customer Loyalty: Branded eyewear can foster a sense of trust and loyalty among customers, as they associate the product with your brand’s quality.

Professional Appearance: A well-designed logo adds a professional touch, enhancing the overall aesthetic and perceived value of the eyewear.

Customization: Logos can be tailored to reflect your brand’s identity, allowing for creative expression and alignment with marketing strategies.

3. What materials can custom logos be applied to?

Custom logos can be applied to various materials used in eyewear manufacturing, each with its unique properties and compatible logo application techniques. Below is a table that outlines the materials, their characteristics, and suitable logo techniques:

Material | Characteristics | Suitable Logo Techniques |

|---|---|---|

Acetate | Durable, high-end finish | Laser Engraving, Screen Printing, UV Printing, Inlay |

Plastic | Lightweight, budget-friendly | Screen Printing, UV Printing, Surface Lasering |

Metal | Sleek, modern, and sturdy | Deep Lasering, Metal Inlay, Surface Lasering |

TR90 | Flexible, lightweight, and impact-resistant | Surface Lasering, UV Printing |

Wood | Eco-friendly, natural aesthetics | Engraving, Inlay, Screen Printing |

4. What are the most common methods for applying logos to eyewear?

Several techniques are used to apply custom logos on eyewear, each suited to different materials and desired effects:

Laser Engraving: Uses lasers to etch the logo into the frame’s surface; suitable for metal, acetate, and plastic.

Screen Printing: Involves transferring ink through a screen to create a vibrant, multicolor logo; ideal for plastic and acetate frames.

Deep Lasering: Engraves the logo deeply into the material, often filled with color for contrast; best for metal frames.

UV Printing: Uses UV light to cure the printed logo, resulting in a durable and high-definition finish; works well on plastic and acetate.

Metal Inlay: A metal logo is inlaid into a pre-engraved groove on the frame, creating a luxurious, embedded look.

5. Can I choose the placement of my custom logo on the eyewear?

Yes, you can typically choose the placement of your custom logo on various parts of the eyewear, depending on the design and the logo application method. Common placement options include:

Placement Option | Description |

|---|---|

Temples | Most common; ample space for logos, highly visible |

Nose Bridge | Subtle branding; best for small logos or initials |

Lens Corners | Discreet placement, commonly used on sunglasses |

Inner Arms | Hidden branding, visible when eyewear is removed |

Temple Tips | Unique option, adds branding at the end of the temple arms, less common but effective |

The placement can influence the visibility and impact of the logo, and the best choice often depends on the frame’s design and the brand’s objectives.

6. What colors are available for custom logos on eyewear?

The color options for custom logos on eyewear are extensive and can be tailored to match your brand’s palette. Common color choices include:

Metallic Finishes: Gold, silver, and bronze for a luxurious, premium look.

Solid Colors: Black, white, and other solid colors for a classic, clean appearance.

Vibrant UV Colors: UV printing allows for bright, vibrant colors like red, blue, and green, offering high visibility.

Multicolor Designs: Screen printing enables the use of multiple colors in one logo, ideal for complex brand logos.

Transparent/Matte Finishes: For a subtle, elegant branding that blends seamlessly with the frame material.

The choice of color can greatly influence the logo’s visibility and aesthetic, making it important to select colors that align with your brand’s image and the eyewear’s design.

7. What is the difference between surface lasering and deep lasering for logos?

Surface Lasering:

Technique: Involves removing the top layer of material to expose the base color underneath.

Effect: Produces a subtle, engraved look that is usually less pronounced; ideal for delicate or intricate logos.

Materials: Suitable for a variety of materials, including plastic, acetate, and metal.

Durability: While durable, it’s less resistant to wear than deep lasering.

Deep Lasering:

Technique: Uses a higher power laser to engrave deeply into the material, creating a more pronounced, tactile logo.

Effect: The logo has a 3D effect and can be filled with color to enhance visibility.

Materials: Best for metal frames; also works on certain plastics.

Durability: Highly durable, withstanding wear, fading, and corrosion over time.

The choice between surface and deep lasering depends on the desired look and the material of the eyewear.

8. How durable are custom logos on eyewear?

The durability of custom logos on eyewear depends on the application method and material used:

Laser Engraving: Offers high durability as the logo is etched into the material, making it resistant to wear and fading.

Deep Lasering: Even more durable, especially when applied to metal frames, as it creates a deeper engraving.

Screen Printing: Provides good durability but may wear off over time, particularly if exposed to harsh conditions or frequent handling.

UV Printing: Offers excellent durability, with logos that resist fading and wear due to the curing process.

Metal Inlay: Extremely durable as the metal logo is embedded into the frame, protected from external damage.

Epoxy Coating: Adds an extra layer of protection, making the logo resistant to scratches and wear.

Logos applied using durable methods like deep lasering or metal inlay are long-lasting and ideal for high-quality eyewear.

9. Can I use a multicolor logo on my eyewear?

Yes, you can use a multicolor logo on your eyewear, depending on the logo application method:

Screen Printing: Allows for precise application of multiple colors, making it ideal for logos with complex color schemes.

UV Printing: Also supports multicolor designs, with the added benefit of vibrant, long-lasting colors that resist fading.

Laser Engraving with Color Fill: Deep laser-engraved logos can be filled with different colors to create a multicolor effect, although the range of colors may be more limited compared to printing methods.

Multicolor logos are especially effective in making your brand stand out, offering a dynamic and visually appealing look that can attract more attention to your eyewear products.

10. What is the minimum order quantity for custom logo eyewear?

The minimum order quantity (MOQ) for custom logo eyewear varies by manufacturer and the complexity of the customization. Here’s a breakdown:

Order Type | Minimum Order Quantity (MOQ) | Notes |

|---|---|---|

Small-Scale Customization | 100 – 300 units | Ideal for simpler techniques like surface lasering or screen printing |

Complex Customization | 300 – 500 units | Higher MOQ for methods like deep lasering or metal inlay |

Bulk Orders | 500+ units | Cost-effective for large-scale production with potential discounts |

The MOQ is an important factor to consider when planning your custom logo eyewear production, as it impacts both cost and logistics.

11. How long does the custom logo process take?

The timeline for completing the custom logo process on eyewear depends on several factors:

Design Finalization: Finalizing the logo design and approval process can take 1-2 weeks, depending on revisions and communication speed.

Production Method: The complexity of the chosen logo application method influences the production time.

Laser Engraving: Typically takes 2-3 weeks.

Screen Printing: Around 2-4 weeks, depending on the complexity and number of colors.

Metal Inlay: May require 3-4 weeks due to the intricate process.

Order Quantity: Larger orders may require additional time, with production timelines extending by an extra 1-2 weeks for bulk quantities.

Overall, from design approval to the final product, you can expect the custom logo process to take approximately 3-6 weeks.

12. Can I see a sample before placing a bulk order?

Yes, most manufacturers offer the option to produce a sample before committing to a full production run. Here’s what you can expect:

Sample Production: Typically takes 1-2 weeks, allowing you to evaluate the quality, color, placement, and overall look of the logo on the eyewear.

Cost: A sample usually incurs an additional fee, which might be credited towards the final order if you proceed with bulk production.

Revisions: After reviewing the sample, you can request changes to the design, placement, or color before finalizing the bulk order.

Receiving a sample is a crucial step in ensuring that the custom logo meets your expectations, reducing the risk of issues in the larger production run.

13. Is it possible to have a 3D logo on eyewear?

Yes, it is possible to create a 3D logo on eyewear using specific techniques:

3D Logo Method | Description | Best Used On |

|---|---|---|

3D Hot Stamping | Embosses the logo into the frame, creating a raised, tactile effect | Plastic, acetate |

Metal Inlay | Embeds a metal logo into a pre-engraved groove, giving it a three-dimensional appearance | Acetate, wood, high-end frames |

Deep Lasering + Color Fill | Engraves deeply into the material and adds color to enhance the 3D appearance | Metal, certain plastics, acetate |

A 3D logo adds a unique, luxurious touch to the eyewear, making it a popular choice for high-end brands looking to differentiate their products.

14. What is the cost of adding a custom logo to eyewear?

The cost of adding a custom logo to eyewear varies based on several factors:

Logo Application Method: Different techniques have different costs:

Screen Printing: Generally the most affordable, ranging from $0.50 to $1 per unit.

Laser Engraving: Moderately priced, typically costing $1 to $3 per unit.

Metal Inlay or Deep Lasering: Higher-end techniques that can cost between $3 to $5 or more per unit.

Order Quantity: Larger orders usually reduce the per-unit cost due to economies of scale.

Complexity of Design: More intricate logos may require additional setup and production time, increasing the overall cost.

Custom logo costs should be factored into your overall budget, especially when planning for large-scale production.

15. Can custom logos be applied to both prescription glasses and sunglasses?

Yes, custom logos can be applied to both prescription glasses and sunglasses. Here’s how they differ:

Prescription Glasses: Logos are typically placed on the temples or inner arms to maintain a subtle, professional appearance. Techniques like laser engraving or inlaid metal logos are popular for adding a touch of sophistication without overwhelming the design.

Sunglasses: Logos on sunglasses can be more prominent, often placed on the outer temples, nose bridge, or even lens corners. UV printing and screen printing are commonly used for vibrant, eye-catching logos that stand out in outdoor settings.

Whether for prescription glasses or sunglasses, custom logos help reinforce brand identity across all product lines.

16. What file format should I provide for my logo?

When submitting a logo for customization on eyewear, it’s essential to provide the correct file format to ensure the highest quality reproduction:

Preferred Formats:

Vector Files (AI, EPS, SVG): These formats are scalable without losing quality, making them ideal for precise logo application.

Alternate Formats:

High-Resolution PNG or PDF: Acceptable if vector files are unavailable, but the logo must be at least 300 DPI for clarity.

Additional Requirements:

Outline Fonts: Convert any text in your logo to outlines to avoid font substitution issues.

Color Codes: Provide specific Pantone or CMYK color codes to ensure accurate color matching in the final product.

Providing the correct file format ensures that your logo is reproduced accurately and meets your branding standards.

17. Are there size limitations for custom logos on eyewear?

Yes, there are size limitations for custom logos on eyewear, which vary based on the placement and application method. Here’s a summary:

Placement Area | Typical Logo Size Range | Notes |

|---|---|---|

Temples | 5mm to 20mm in length | Most popular area; ample space for visibility |

Lens Corners | 2mm to 5mm | Discreet placement to avoid obstructing vision |

Nose Bridge | Typically less than 5mm | Best for small, subtle logos |

Inner Arms | Up to 15mm in length | Ideal for hidden branding; less visible but still effective |

Temple Tips | Varies, generally small; adds a unique branding touch | Uncommon placement, provides a creative branding opportunity |

The exact size limits depend on the specific frame design and the logo application technique used, so it’s important to work with your manufacturer to determine the optimal size.

18. Can I update or change my logo design after placing an order?

Updating or changing a logo design after placing an order can be challenging and often depends on the production stage:

Before Production Starts: Changes are usually possible and may involve minimal additional costs, mainly for design adjustments.

After Production Begins: Once production has started, changes become more difficult and costly, as materials may already be in use and machinery set up. Alterations might require stopping production, which could result in delays and higher expenses.

Best Practice: Finalize and confirm your logo design before placing the order to avoid the need for changes later on.

Clear communication with your supplier about any potential changes is crucial to minimize disruptions and ensure you get the desired result.

19. What is the difference between an inlaid metal logo and a UV sticker logo?

Feature | Inlaid Metal Logo | UV Sticker Logo |

|---|---|---|

Process | Metal logo piece is embedded into an engraved groove | Sticker is applied to the frame surface using UV curing technology |

Materials | Acetate, wood, plastic | Acetate |

Appearance | Luxurious, 3D effect with a tactile, embedded look | Sleek, shiny, flush with the frame surface |

Durability | Extremely durable, resistant to wear and tear | Durable but may wear off over time, especially with frequent handling |

Typical Usage | High-end, premium eyewear brands | Sleek, subtle branding on acetate frames |

Both methods offer distinct aesthetic and functional benefits, depending on the desired branding outcome.

20. What happens if the custom logo wears off or gets damaged?

The durability of your custom logo depends largely on the method used:

High-Durability Methods: Techniques like deep lasering, metal inlay, and epoxy coating are highly resistant to wear and unlikely to fade or get damaged under normal conditions.

Less Durable Methods: Screen printing and UV stickers may wear off over time, especially with frequent use or exposure to harsh conditions.

Repair Options: If a logo does wear off or get damaged, some manufacturers offer repair or re-application services, though this may incur additional costs. It’s advisable to inquire about warranty or repair policies before production.

Choosing the right logo application method and taking proper care of the eyewear can significantly extend the lifespan of the custom logo.

This comprehensive guide, incorporating tables where useful, should provide a clear and detailed understanding of the key aspects of custom logos on eyewear.

"We cater to a high-end clientele, so the logo on our eyewear needs to be not only beautiful but also sophisticated. Eyewearbeyond’s performance in logo customization was outstanding. We chose laser engraving, and the logo was seamlessly integrated into the frame, offering a discreet yet luxurious look. Communication was smooth throughout the process, delivery was on time, and the product quality was impeccable. Our customers are really impressed with these personalized glasses, and our sales have seen a significant boost."

"As an e-commerce brand focused on personalization, we wanted our products to truly reflect our brand’s unique style. Eyewearbeyond’s team provided a variety of logo customization options, from colorful printing to intricate laser engraving, and each suggestion perfectly matched our brand’s aesthetic. The final product not only looked stylish and creative but the detailed logo work made the entire product feel premium. This collaboration has greatly enhanced our brand visibility, and our customers have been giving rave reviews about the unique designs."

Before we start crafting your unique eyewear collection, we need specific details about your designs. Please complete the form below. We’ll swiftly review your submission and provide a quote and next steps.

Follow Us:

Set your brand apart with custom-designed eyewear! At Eyewearbeyond, we specialize in tailor-made eyeglasses and sunglasses that fit your specifications. Request a quote and start designing now!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Ready to bring your unique eyewear designs to life? Start your journey to custom eyewear today—request your free quote now!

Your email information will be kept strictly confidential and our business staff will ensure that your private information is absolutely safe!

Looking for the perfect custom eyewear to represent your brand?

Our experts can help you find the perfect eyewear solution tailored to your requirements!

You have successfully subscribed to the newsletter

There was an error while trying to send your request. Please try again.